Variable cross-section and multistage heating screw arbor for self-cooked instant noodle extrusion equipment

A technology of multi-stage heating and variable cross-section, applied in the field of food machinery, can solve problems such as difficulty in meeting the technical requirements of the degree of rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better explain the present invention and facilitate the understanding of the technical solutions of the present invention, typical but non-limiting examples of the present invention are as follows. A circular orbit industrial robot for processing large workpieces mentioned in the contents of the present invention will be described with reference to the figure, which is used for processing large aluminum castings.

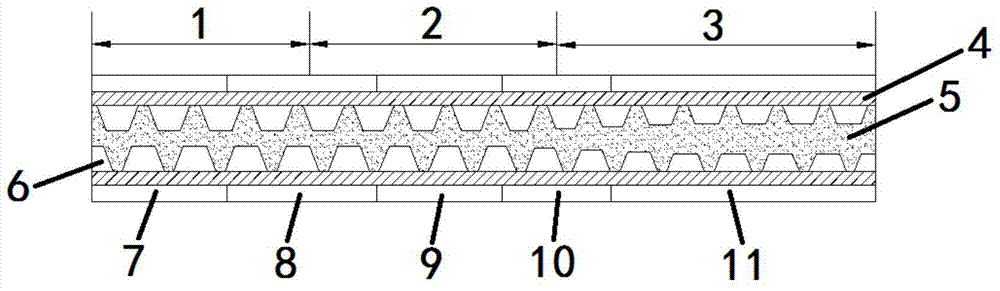

[0017] The length of the screw processing zone is 1.735m, the length of the first stage is 482mm, the length of the second stage is 548mm, and the length of the third stage is 706mm. The five-stage heating is the first stage heating zone, the first transition heating zone, the second stage heating zone, and the second stage heating zone. Second transition heating zone, third stage heating zone; use ABAQUS computer simulation software to simulate the surface processing process to determine the optimal cross-sectional area and heating temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com