Dot-matrix prefabricated optical cable and manufacture method thereof

A prefabricated optical cable, lattice technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of large size of fusion box, low yield of finished products, high cost of 12 cores, high optical fiber density, low insertion loss, Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

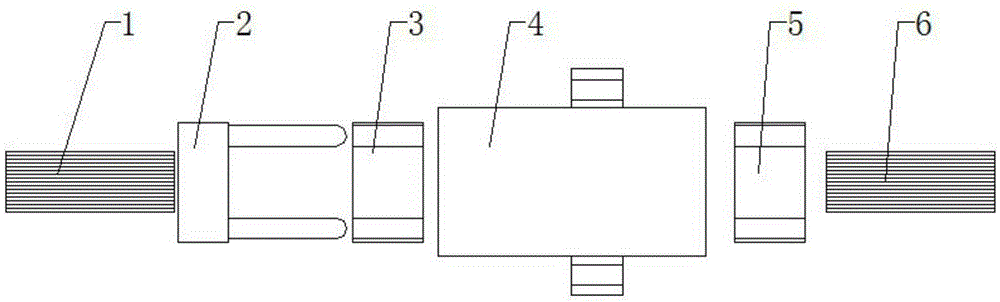

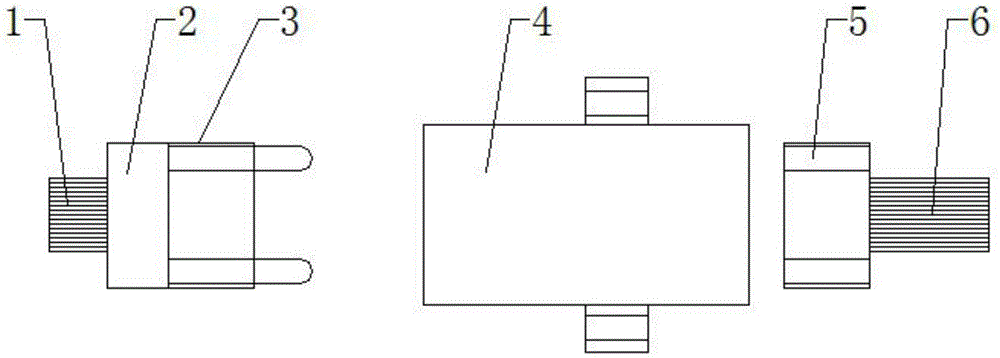

[0041] Embodiment 1: as figure 1 and figure 2 As shown, dot-matrix prefabricated optical cables, including

[0042] An optical cable, including a male-end optical fiber 1 and a female-end optical fiber 6;

[0043] Male end assembly, located at one end of the optical cable, for connection;

[0044] The female end assembly is located at the end of the optical cable away from the male end assembly and is used in conjunction with the male end assembly;

[0045] The fixing seat 4 is used for fixedly connecting the male end assembly and the female end assembly.

[0046] The male end assembly includes a positioning pin 2 and a male end ferrule 3. The male end ferrule 3 is provided with several through holes for fixing the optical cable and positioning holes for the positioning pin 2 to pass through.

[0047] The female end assembly includes a female end ferrule 5, and the female end ferrule 5 is provided with several through holes for fixing optical cables and positioning holes ...

Embodiment 2

[0058] Embodiment 2: Dot matrix prefabricated optical cable, the diameter of the through hole is 0.1256mm. All the other contents are the same as in Example 1.

Embodiment 3

[0059] Embodiment 3: Dot matrix prefabricated optical cable, the diameter of the through hole is 0.1258mm. All the other contents are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com