Direct current power transmission engineering valve group overhauling automation isolation realization method

A valve group maintenance isolation, direct current transmission technology, applied in the direction of electrical components, circuit devices, switchgear, etc., can solve problems such as unsafe operation, difficulty in judging and taking measures, interference with operating equipment, etc., to achieve safe and reliable operation, The effect of reducing workload and technical ability requirements and avoiding unreliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

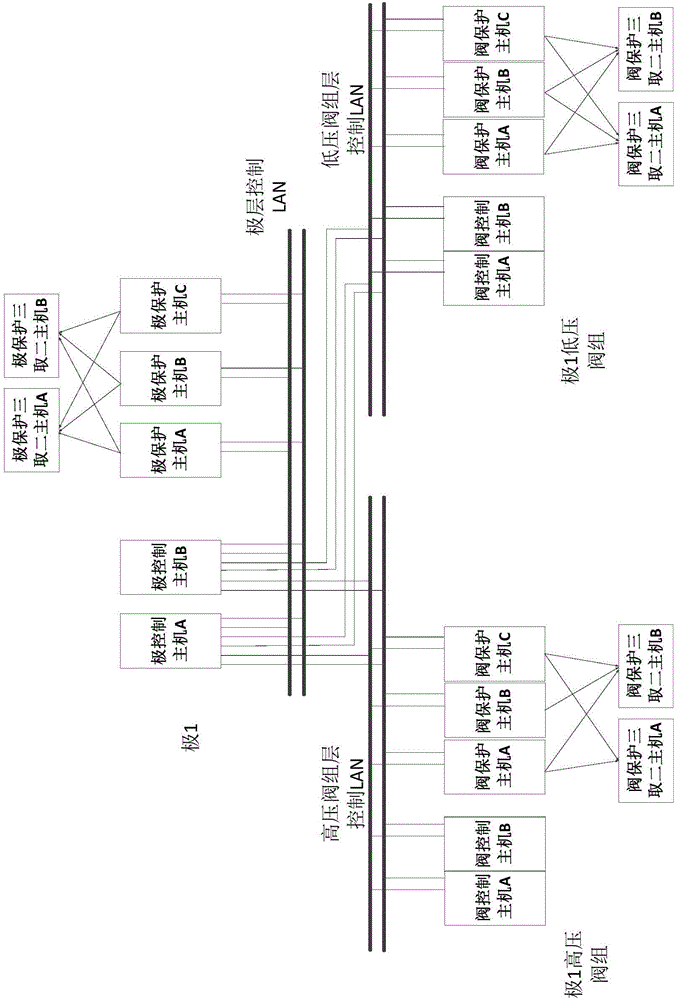

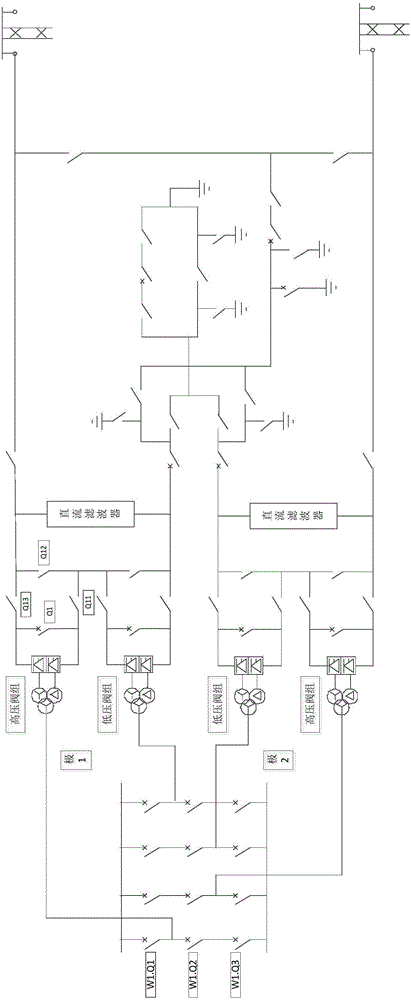

[0023] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

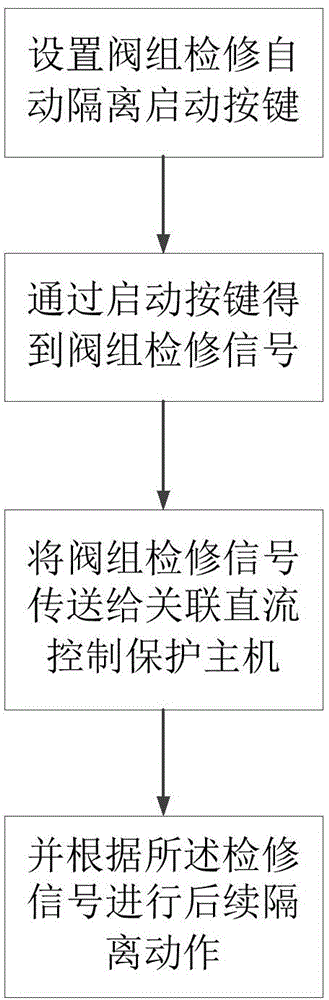

[0024] The present invention provides a method for realizing the automatic isolation function of valve group maintenance in a direct current transmission project, which includes the following steps:

[0025] (1) Set the automatic isolation start button for valve group inspection, and get the valve group inspection signal through the start button. One method is to install physical buttons, each valve group corresponds to a maintenance button, the control and protection host of the maintenance valve group, and the extreme control host obtain the valve group maintenance signal through direct collection, and the extreme control host communicates the valve group through the communication between the hosts. The inspection signal is transmitted to the main engine of extreme protection and the control and protection of the non-inspection valve grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com