Processing system and processing method of safe automatic coloring of picked fruits and vegetables

A technology of safe automation and processing system, which is applied in the field of safe automatic color conversion processing system for fruits and vegetables after harvest, can solve the problems of fruit dehydration and softening, peel damage, inaccurate control of degreening parameters, etc. The effect of improving the value of appearance goods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

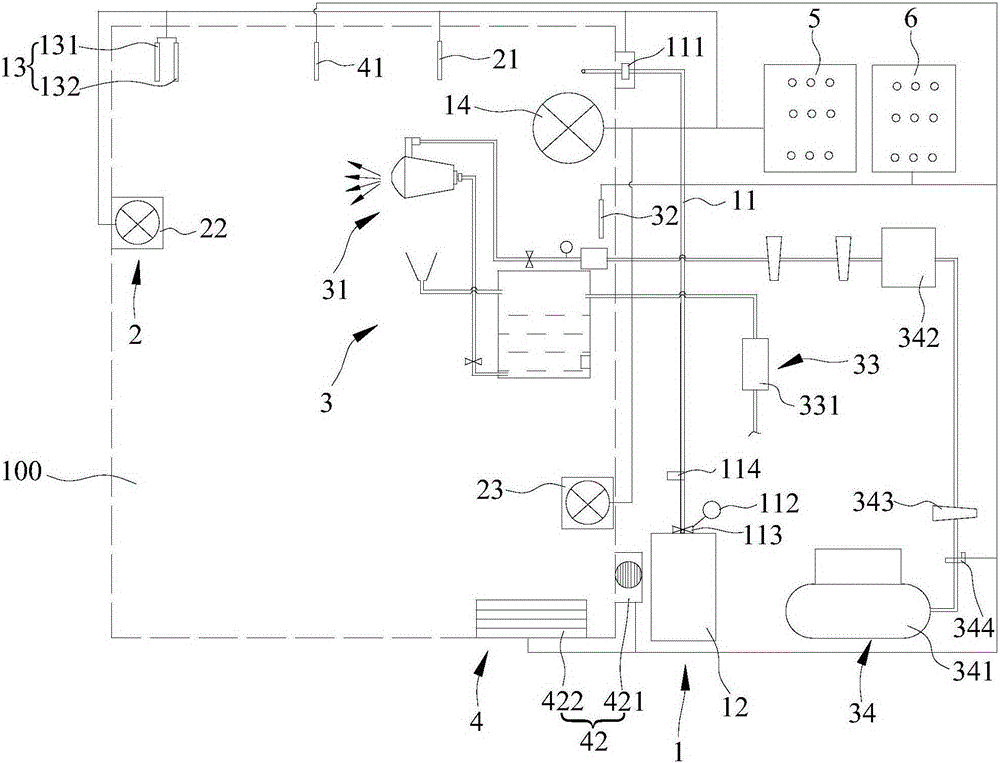

[0036] Attached below figure 1 And further illustrate the technical solution of the present invention through specific examples.

[0037] figure 1 It is a schematic diagram of a safe automatic color-changing processing system for harvested fruits and vegetables according to an embodiment of the present invention. like figure 1 As shown, a safety automatic color change processing system for harvested fruits and vegetables includes a storage warehouse 100, an ethylene control system 1 connected to the storage warehouse 100 and a CO 2 Control system 2, ethylene control system 1 includes an ethylene delivery pipe 11, the outlet end of the ethylene delivery pipe 11 is set in the storage 100, the inlet end of the ethylene delivery pipe 11 is connected to the ethylene gas tank 12, and the ethylene delivery pipe 11 is provided with a solenoid valve 111. The ethylene control system 1 further includes an ethylene sensor 13 arranged in the storage 100, CO 2 Control system 2 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com