Wet wound dressing and preparation method thereof

A wound, wet technology, used in the field of medicine, to achieve good antibacterial properties, good application potential, and a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

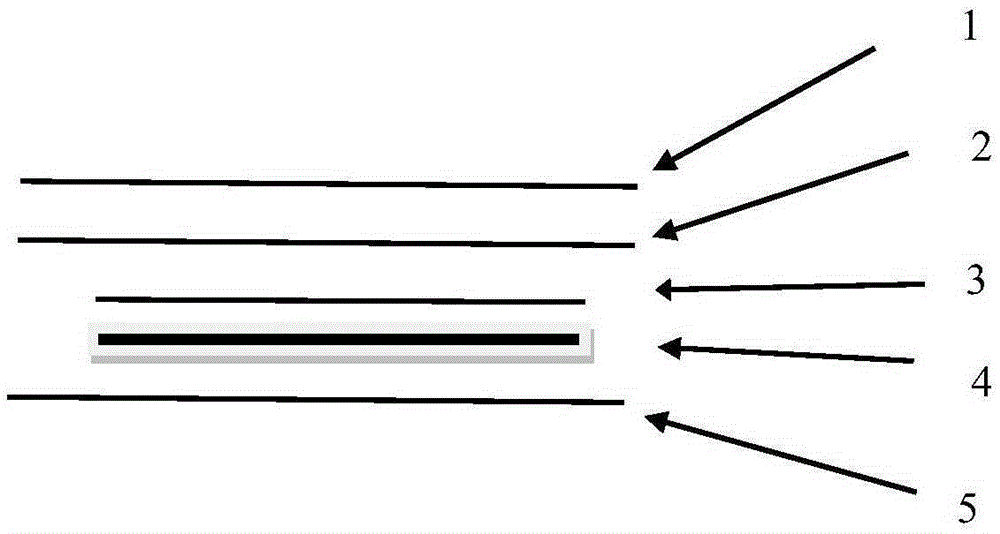

Image

Examples

Embodiment 1

[0040] Get 1,000 grams of honey and 1,000 grams of ethanol solution and mix them uniformly on a shaker (at a temperature of 37 degrees Celsius for 6 hours) to obtain the honey ethanol solution as component A; get 5 grams of vitamins, 5 grams of sodium carboxymethylcellulose, and 5 grams of growth factors 1. Add 5 grams of antibacterial agent to component A, and stir at 37 degrees Celsius for 6 hours to obtain component B by temperature-controlled electric stirring; take 300 grams of maltodextrin and 30 grams of β-cyclodextrin in component B , electronically stirred at 37 degrees Celsius for 12 hours by temperature control, and then ultrasonicated by an ultrasonic mixer for 3 hours. %, the air inlet temperature is 180 degrees Celsius, the air inlet volume is 100%, and the outlet air temperature is 85 degrees Celsius. After drying, the target object of the first product is D component; the D component is pulverized by an ultrafine pulverizer, and then filtered with a filter The ...

Embodiment 2

[0042] Get 1000 grams of honey and 2000 grams of ethanol solution and mix it uniformly for 6 hours under a shaker temperature of 37 degrees Celsius to obtain the honey ethanol solution as component A; get 10 grams of vitamins, 5 grams of sodium carboxymethyl cellulose, 10 grams of growth factors, antibacterial Add 5 grams of maltodextrin to component A, and stir at 37 degrees Celsius for 6 hours to obtain component B by temperature-controlled electric stirring; take 330 grams of maltodextrin and 30 grams of β-cyclodextrin in component B, and Temperature-controlled electronic stirring at 37 degrees Celsius for 12 hours, and then ultrasonic mixer for 3 hours, the solution after mixing evenly is C component; C component is dried by spraying, and its main process parameters are: the feed amount is 20%, The air inlet temperature is 180 degrees Celsius, the air inlet volume is 100%, and the air outlet temperature is 85 degrees Celsius. After drying, the target product of the first pr...

Embodiment 3

[0044]Get 1000 grams of honey and 3000 grams of ethanol solution and mix it uniformly for 6 hours under a shaker temperature of 37 degrees Celsius to obtain the honey ethanol solution as component A; get 5 grams of vitamins, 10 grams of sodium carboxymethyl cellulose, 5 grams of growth factors, antibacterial Add 10 grams of maltodextrin to component A, and stir at 37 degrees Celsius for 6 hours to obtain component B by temperature-controlled electric stirring; take 360 grams of maltodextrin and 30 grams of β-cyclodextrin in component B, and Temperature-controlled electronic stirring at 37 degrees Celsius for 12 hours, and then ultrasonic mixer for 3 hours, the solution after mixing evenly is C component; C component is dried by spraying, and its main process parameters are: the feed amount is 20%, The air inlet temperature is 180 degrees Celsius, the air inlet volume is 100%, and the air outlet temperature is 85 degrees Celsius. After drying, the target product of the first p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com