Novel demister

A demister, a new type of technology, applied in chemical instruments and methods, separation methods, liquid degassing, etc., can solve the problems of difficulty in reaching the concentration of fog droplets and particulate matter at the exhaust port, and low removal efficiency of small particle size droplets. To achieve the effect of flexible use, novel structure design, and reduction of secondary entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

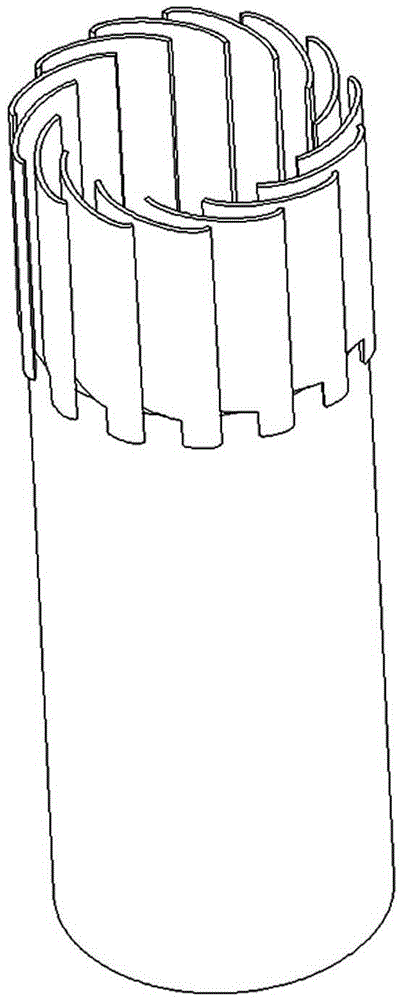

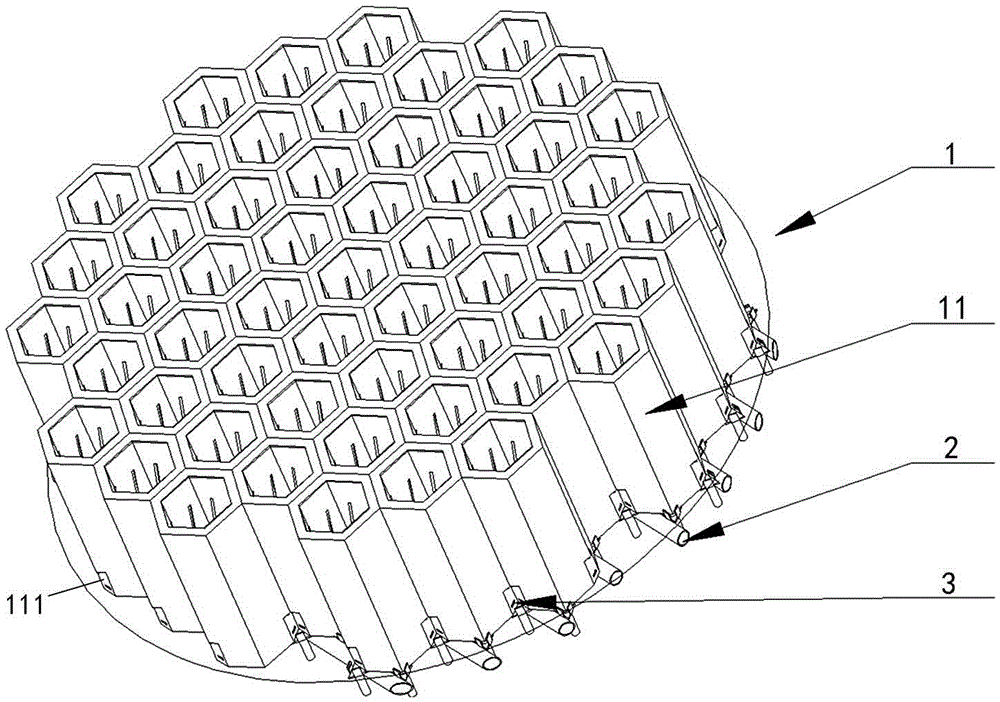

[0045] Such as figure 1 , figure 2 , image 3 , Figure 6 A new type of mist eliminator, including a plurality of demisting units 1 spliced into a honeycomb shape. At the periphery of the flow tube 12 , at least one flow guide tube 12 is arranged in a liquid collecting tube 11 . The primary swirl vane set 13 is installed in the guide tube 12 and is located at the air inlet end thereof. The side wall of the guide tube 12 is provided with a water-permeable structure, and there is a gap between the outer wall surface of the guide tube 12 and the inner wall surface of the liquid collection tube 11 to form a water-passing interlayer cavity 14, and the bottom of the interlayer cavity 14 is connected to the External drain connection.

[0046] The cylinder body of the liquid collecting cylinder 11 is preferably in the shape of a regular hexagon, which facilitates the seamless splicing of adjacent demisting units. A butterfly-shaped bottom plate is provided below the interlaye...

Embodiment 2

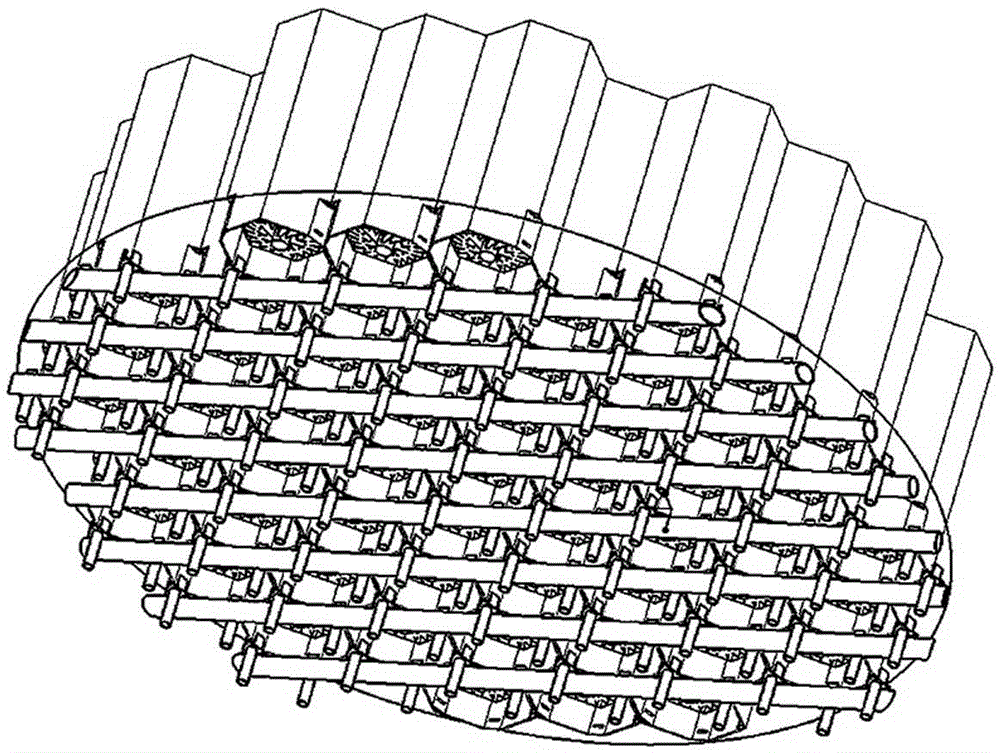

[0051] On the basis of Embodiment 1, the honeycomb structure of the liquid collection cylinder 11 can be further simplified, and the liquid collection cylinder 11 is set as Figure 4 , Figure 5 In the structural form shown, a plurality of guide tubes 12 can be arranged in each liquid collecting cylinder 11, and the cylinder wall of the liquid collecting cylinder 11 is composed of several equal-width wall plates connected in sequence, and the included angle between adjacent wall plates is 12°. °, the recess is arranged at the corner of the liquid collection tube 11, so that each guide tube 12 is at least opposite to one wall of the liquid collection tube.

Embodiment 3

[0053] When the mist eliminator is used to separate mist droplets with extremely small particle diameters, such as mist droplets of tens to hundreds of nanometers, several secondary swirl vane groups can be added in the rear section of the primary swirl vane group 13 in the draft guide tube 15. In order to avoid the increased pressure loss of the mist eliminator due to the increase in the number of layers of the blade group, the center piece 151 of the secondary swirl blade group 15 is set as a hollow cylinder, but compared with the blade air inlet of the secondary swirl blade group position, the central piece 151 will be longer on the side facing the air flow. Correspondingly, the interlayer chamber is also separated into separate chamber units, and each chamber unit collects the droplets separated by the corresponding swirl vane groups on each layer, and the drain outlet of the upper chamber unit is connected to the lower chamber unit. Connected, or connected to an external ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com