Ceramic fiber high temperature gas filter and preparation method thereof

A ceramic fiber, high temperature gas technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve problems such as large filtration resistance and easy blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

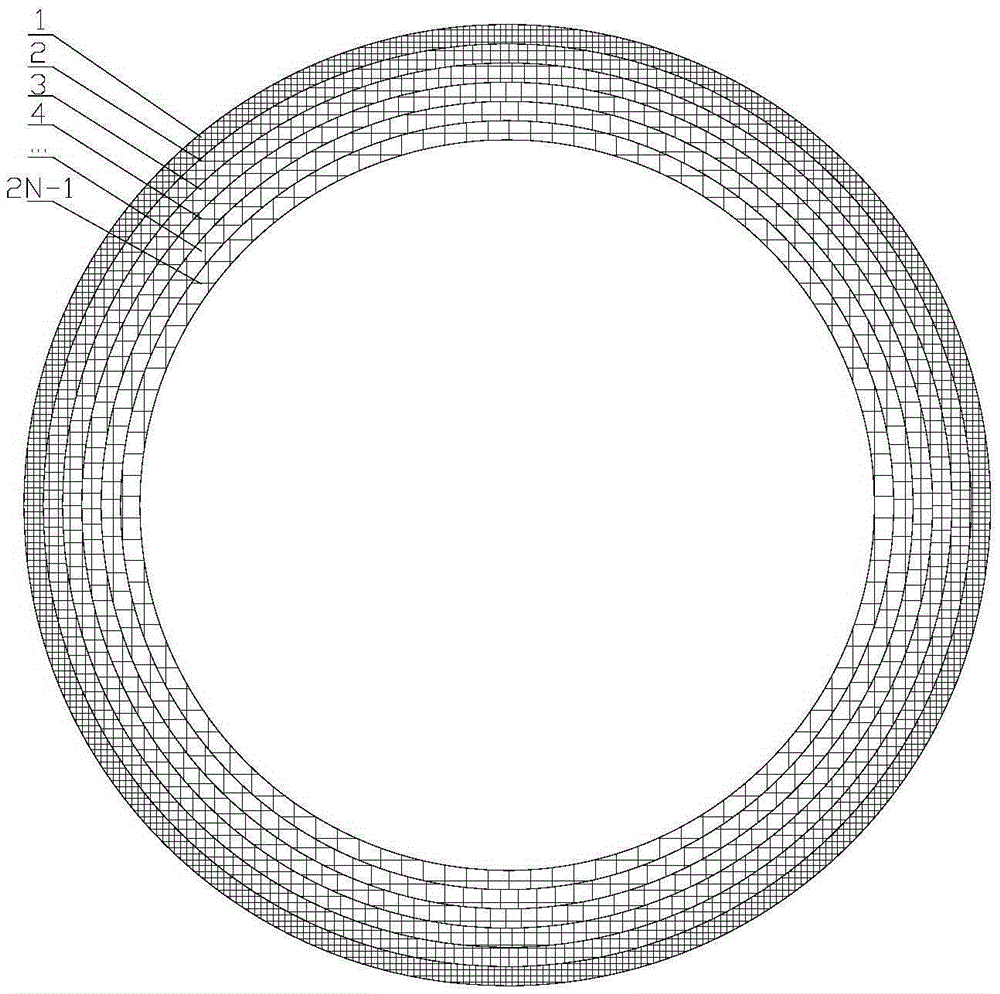

[0017] A method for preparing a ceramic fiber high-temperature gas filter material, comprising the following operations:

[0018] a. Select N kinds of ceramic fibers with different aspect ratio ranges, N≥2;

[0019] b. Mixing the above-mentioned N types of ceramic fibers with different length-to-diameter ratios with binder and dispersant respectively to obtain injection molding slurry;

[0020] c. Inject the ceramic fiber injection molding slurry with the smallest length-to-diameter ratio range into the mold and filter it. The range from small to large is poured into the mold in sequence, and is formed by suction filtration. The formed filter material is dried together with the mold, and then demolded and fired to obtain a ceramic fiber high-temperature gas filter.

[0021] The ceramic fiber is divided into several kinds of slurries with different length-to-diameter ratio ranges by the above method, and the injection molding slurries are injected into the mold according to th...

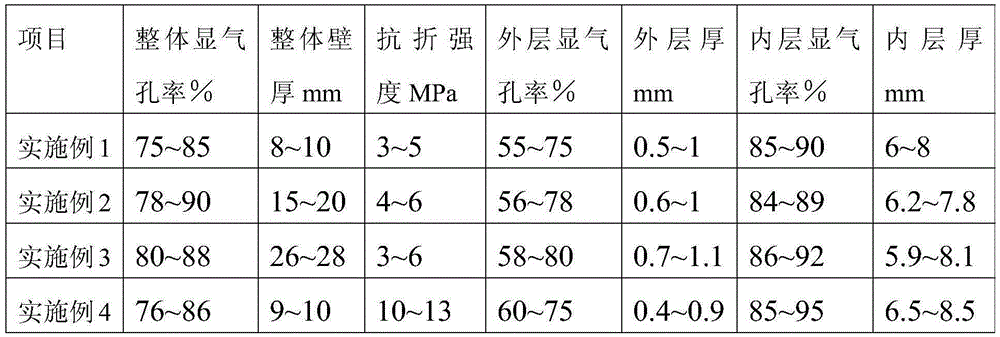

Embodiment 1

[0029] a. Choose two different ceramic fibers with aspect ratios ranging from 1 to 20 and 20 to 60; the ceramic fibers are aluminum silicate fibers.

[0030] b. Mix and stir the above two kinds of ceramic fibers with different length-to-diameter ratios with binder, dispersant, and polypropylene short fibers respectively to obtain injection molding slurry, wherein the above two kinds of ceramic fibers and binder are in mass ratio 0.3:100, 1:100; described binding agent is the mixture of water glass and water, and wherein the mass ratio of water glass and water is 0.1:10; The short fiber of polypropylene accounts for the total mass of ceramic fiber, binding agent 0.01; the short fiber diameter of polypropylene is 10-100 μm, and the fiber length is 10-1000 μm; the amount of dispersant added is 0.1 of the total mass of ceramic fiber and binder.

[0031] c. According to the range of ceramic fiber aspect ratio from small to large, firstly inject the first type of ceramic fiber injec...

Embodiment 2

[0033] a. Choose 4 kinds of high-alumina fibers with aspect ratios ranging from 1 to 20, 20 to 60, 60 to 120, and 120 to 200.

[0034] b. Mix and stir the high-alumina fibers of the above four different length-to-diameter ratio ranges with the short fibers of the dispersant and polyacrylonitrile respectively to obtain the injection molding slurry, wherein the above four kinds of ceramic fibers and the binder are in a mass ratio of 0.3: 100, 0.6:100, 1.2:100, 1.5:100; the binder is a mixture of silica sol and water, wherein the mass ratio of silica sol to water is 0.5:10; short fibers of polyacrylonitrile account for ceramic fibers, The total mass of the binder is 0.03; the short fiber diameter of polyacrylonitrile is 10-20 μm, and the fiber length is 10-1000 μm; the amount of dispersant added is 0.3 of the total mass of the ceramic fiber and the binder.

[0035] c. Inject the injection molding slurry into the mold according to the range of aspect ratio of the ceramic fiber fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com