Equipment for quickly preparing graphene and preparation method of graphene

A graphene and fast technology, which is applied in the field of rapid preparation of graphene equipment and its preparation, can solve the problems of heat loss, prolong the growth cycle, etc., achieve the effects of reducing loss and waste, improving production efficiency, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

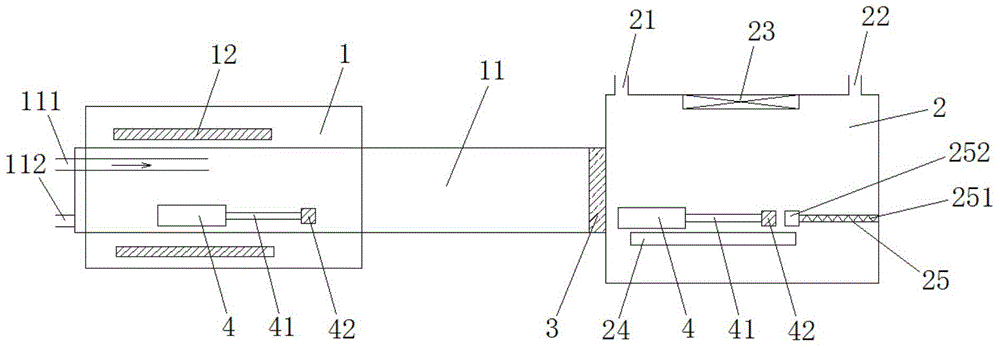

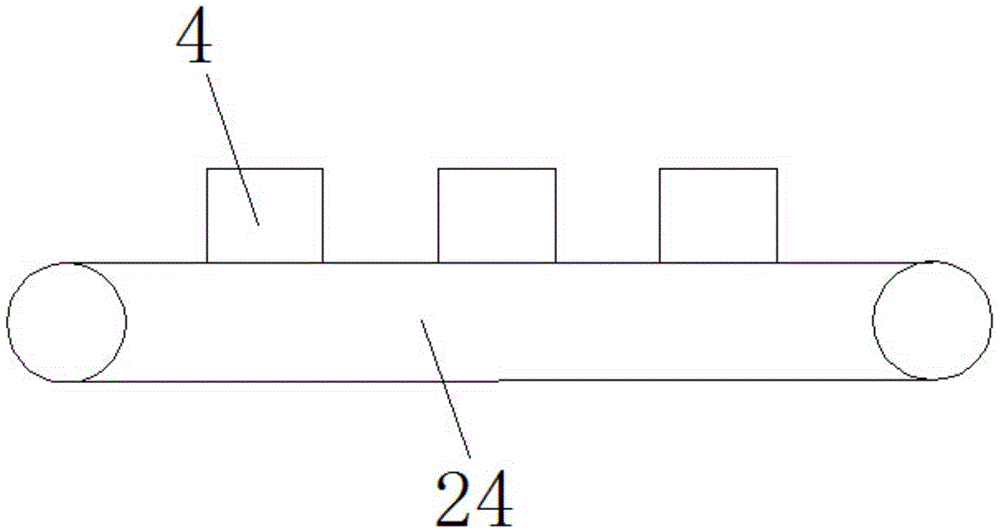

[0036] See figure 1 and figure 2 , the device for rapidly preparing graphene in this embodiment includes a tube furnace 1, a sample loading chamber 2, a vacuum valve 3 and a plurality of sample loading boats 4.

[0037]The tube furnace 1 includes a quartz tube 11, one end of the quartz tube 11 is a heating end, and the other end is connected to the sample loading chamber 2 through a vacuum valve 3, and a heating device 12 is provided outside the heating end of the quartz tube 11. The quartz tube 11 of the tube furnace 1 is provided with a first gas inlet 111 and a first gas outlet 112 . The sample loading chamber 2 is provided with a second air inlet 21 , a second air outlet 22 and a sample loading port 23 . A transposition device 24 and a moving device 25 are arranged in the sample loading cabin 2 . A plurality of sample-carrying boats 4 are placed on the transposition device 24 of the sample loading cabin 2, and the relative positions between the sample-carrying boats 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com