Super-hydrophobic repairable aqueous coating material and preparation method thereof

A water-based coating, super-hydrophobic technology, applied in coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of complex construction of micro-nano structures, achieve recovery of super-hydrophobic properties, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A water-based coating material with repairable superhydrophobic performance, which is composed of water-based polyurethane resin with a mass fraction of 95%, 3% palygorskite and 2% polydopamine capsules coated with octadecylamine.

[0022] Above-mentioned coating material is made by following method:

[0023] (1) Add palygorskite and stearylamine to the Tris-HCl solution of dopamine hydrochloride, the pH of the Tris-HCl solution is 8.3, the concentration of dopamine hydrochloride is 0.01mg / ml, stir for 12h, and filter , washed with water, washed with ethanol, and vacuum-dried to obtain palygorskite / octadecylamine complex;

[0024] (2) Mix the palygorskite / stearylamine compound and water-based polyurethane evenly to obtain the coating material, add curing agent, and spray it on the substrate to obtain the 1# sample.

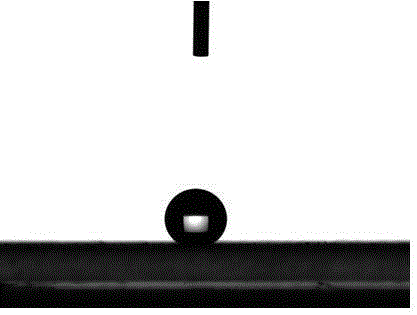

[0025] After the octadecylamine on the surface of the above-mentioned super-hydrophobic repairable coating material is treated with plasma for 5s, it is p...

Embodiment 2

[0027] A water-based coating material with repairable superhydrophobic properties, characterized in that the material is composed of 80% water-based epoxy matrix resin, 15% carbon nanotubes and 0.5% polydopamine capsules coated with perfluorooctyl alcohol composition.

[0028] Above-mentioned waterborne coating material is made by following method:

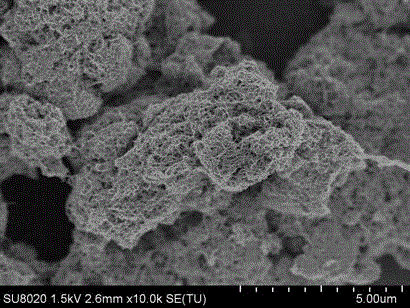

[0029] (1) Add carbon nanotubes and perfluorooctanol to the Tris-HCl solution of dopamine hydrochloride, the pH value of the Tris-HCl solution is 8.5, the concentration of dopamine hydrochloride is 1mg / ml, stir for 12h, filter, Washing with water, washing with ethanol, and drying in vacuum to obtain a carbon nanotube / perfluorooctyl alcohol composite;

[0030] (2) Mix the carbon nanotube / perfluorooctyl alcohol compound and the water-based epoxy resin evenly to get the coating material, and spray it on the substrate to get the 2# sample.

[0031] After the perfluorooctyl alcohol on the surface of the above-mentioned super-hydropho...

Embodiment 3

[0033] A water-based coating material with repairable superhydrophobic performance is characterized in that the material is composed of a water-based acrylic matrix resin with a mass fraction of 10%, carbon nanotubes of 70% and polydopamine capsules coated with perfluorooctanoic acid 20%.

[0034] Above-mentioned waterborne coating material is made by following method:

[0035] (1) Add carbon nanotubes and perfluorooctanoic acid to Tris-HCl solution of dopamine hydrochloride, the pH value of Tris-HCl solution is 8.6, the concentration of dopamine hydrochloride is 10mg / ml, stir for 12h, filter, wash with water, ethanol Wash and dry in vacuum to obtain carbon nanotube / perfluorooctanoic acid composite;

[0036] (2) Mix the carbon nanotube / perfluorooctanoic acid compound and the water-based acrylic resin evenly to obtain the coating material, and spray it on the substrate to obtain the 3# sample.

[0037] The perfluorooctanoic acid on the surface of the above-mentioned super-hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com