A water cooling device for vacuum evaporation equipment for optical filters

A water-cooling device and optical filter technology, which is applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of device failure, device damage, and increased cost, so as to improve work efficiency, The effect of relieving high temperature and prolonging the use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

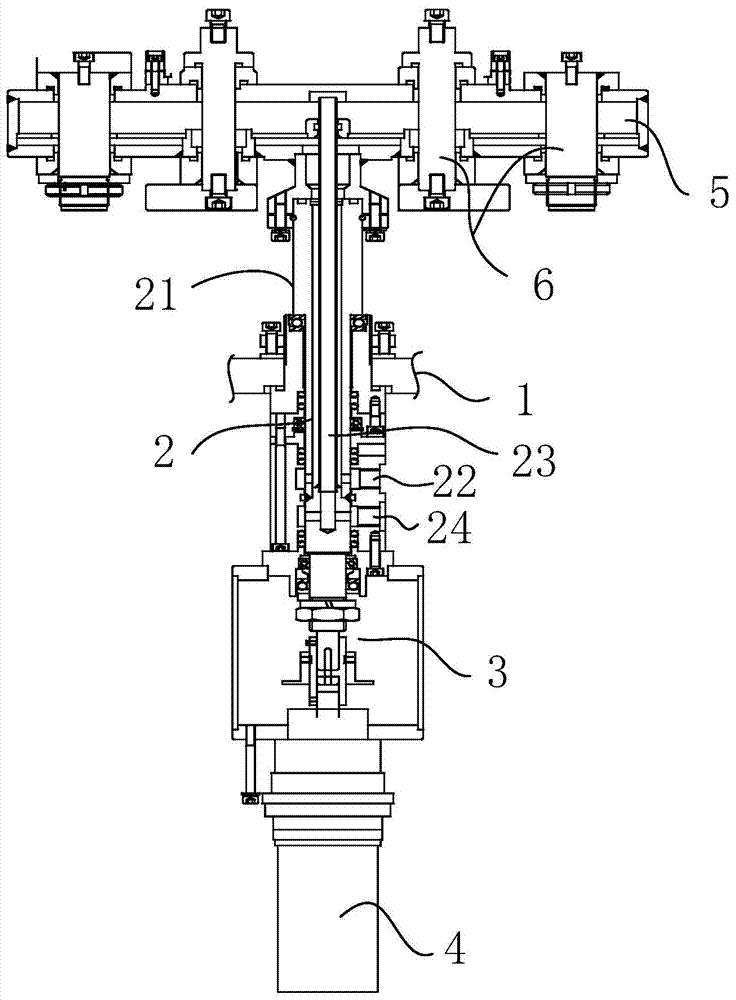

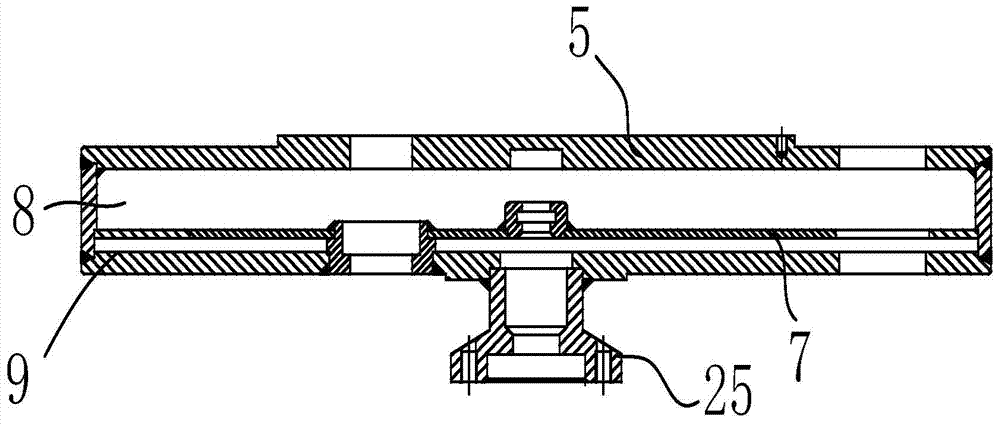

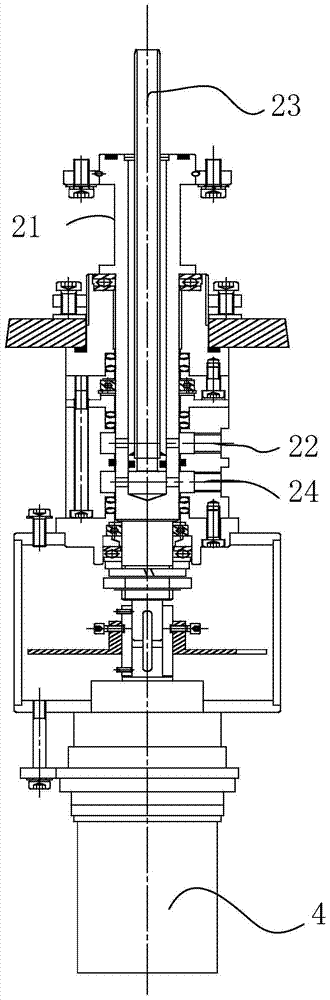

[0037]In Embodiment 1, the present invention provides a water cooling device for vacuum evaporation equipment for optical filters, including: a mounting plate 1, a rotating shaft 2 is connected to the mounting plate 1, and the rotating shaft One end of the shaft 2 is driven and connected to the motor 4 through a coupling 3, and the other end of the rotating shaft 2 is fixed to the bottom end of the water cooling plate 5; the inner cavity of the water cooling plate 5 is divided into an upper chamber layer by a partition 7 8 and the lower cavity layer 9, the partition plate 7 is provided with holes, so that the upper cavity layer 8 and the lower cavity layer 9 are communicated and arranged, and a plurality of electrode rods 6 are plugged on the water cooling plate 5, and the electrode rods 6 The upper and lower ends protrude from the upper and lower ends of the water cooling plate 5; the inner cavity of the rotating shaft 2 is inserted with a water outlet pipe 23, and one end of ...

Embodiment 2

[0039] On the basis of the first embodiment, the present invention proposes the second embodiment. The bottom end of the water-cooling plate 5 in the second embodiment is equipped with a cooling pipe joint 25, and the cooling pipe joint 25 is in a Y-shaped structure. Quick disassembly for operation and easy maintenance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com