Patents

Literature

31results about How to "Relieve high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

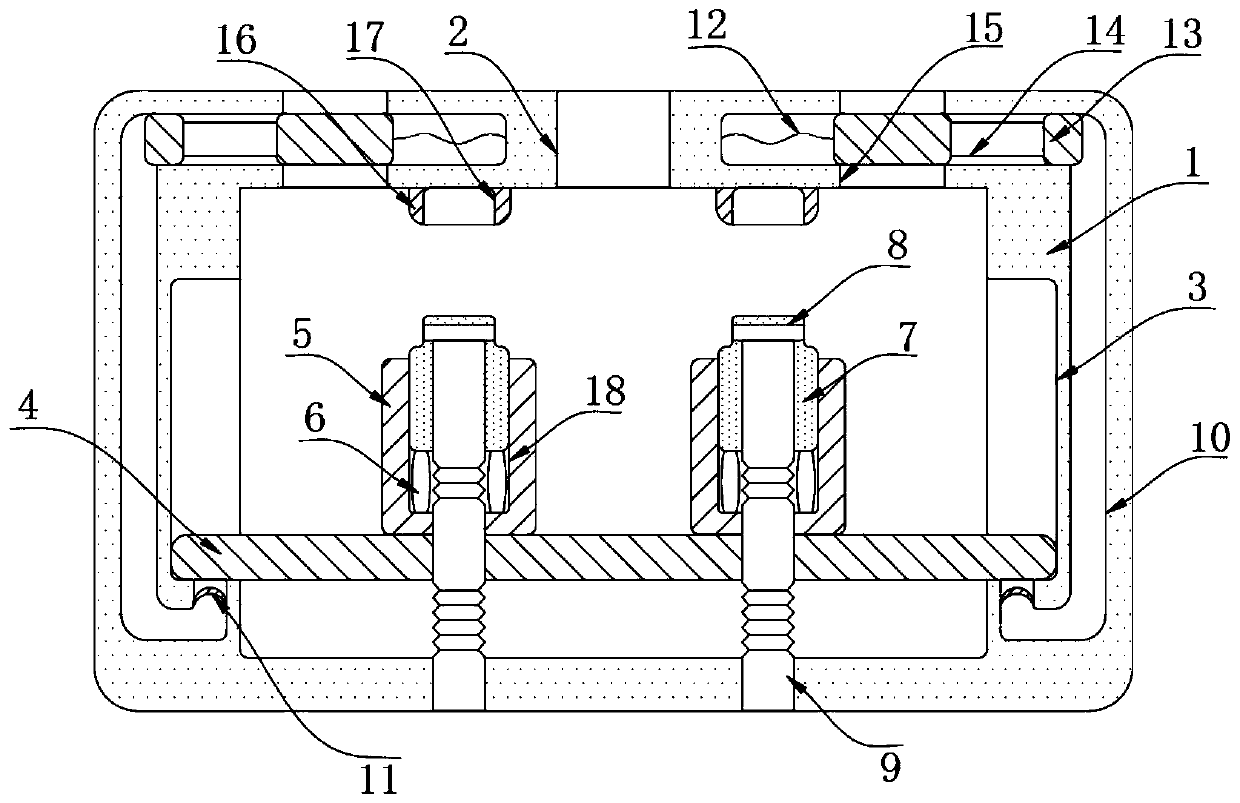

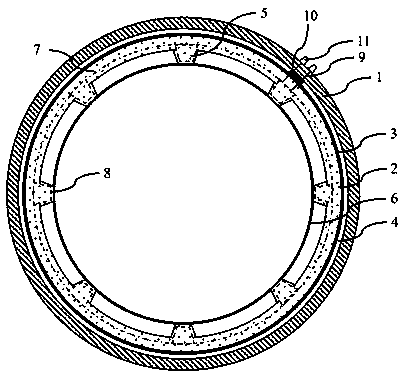

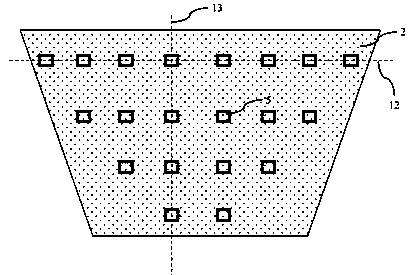

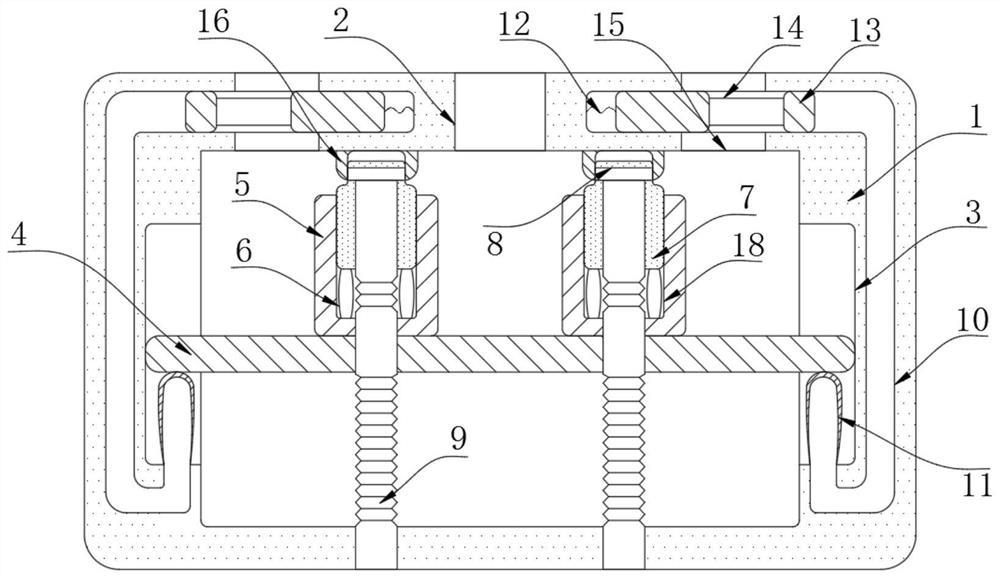

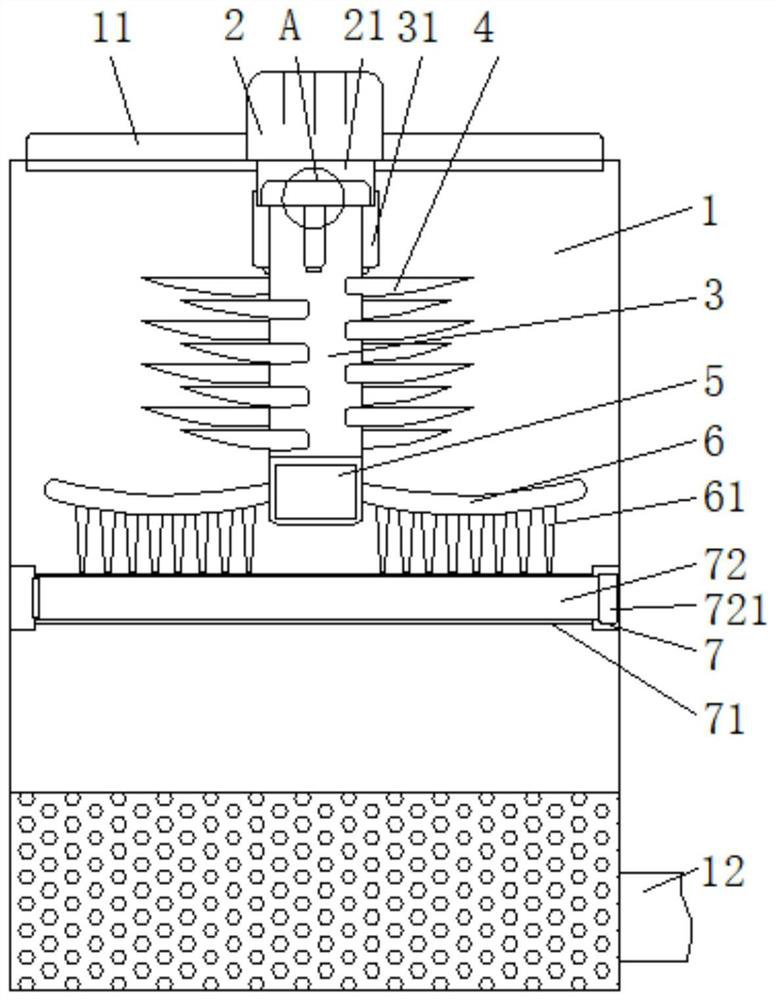

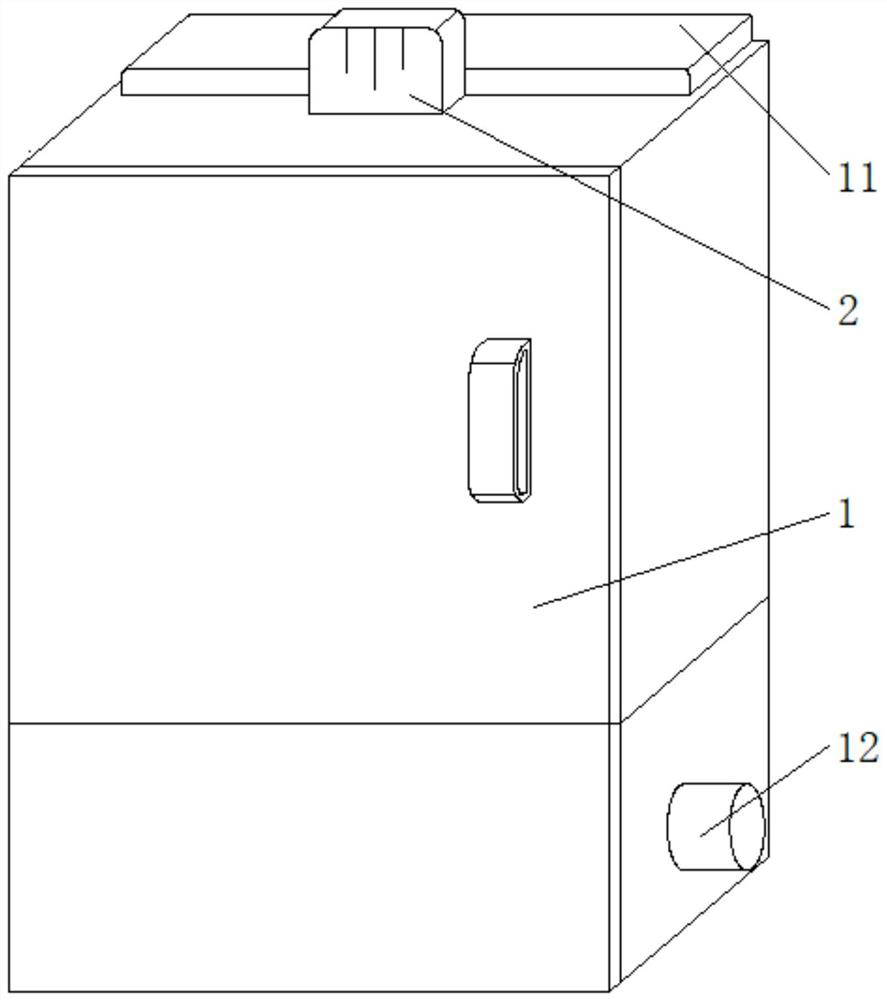

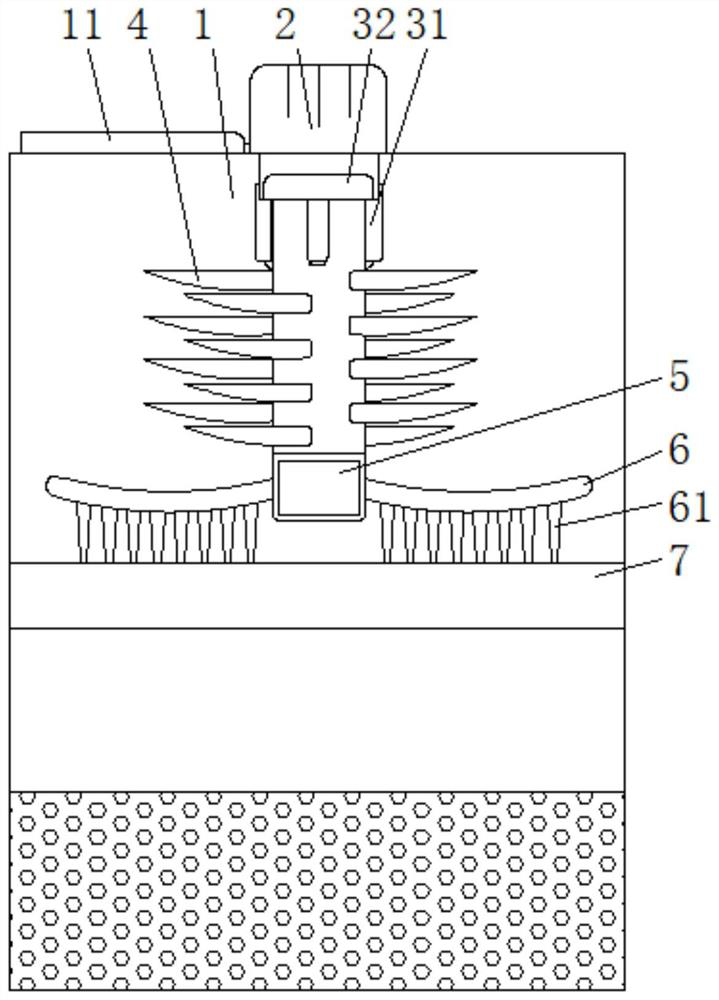

Water permeable brick for sponge city

The invention discloses a water permeable brick for a sponge city. The water permeable brick comprises a hollow brick body. A water inlet is formed in the upper end of the brick body in a penetratingmanner, two symmetrically formed lifting grooves are formed in the inner wall of the brick body, a partition plate leans against the bottoms of the two lifting grooves jointly, two ends of the partition plate are hermetically and slidably connected to the inner walls of the two lifting grooves, separately, a plurality of columns are fixed to the upper end of the partition plate, a chute is formedin the upper end of each column, and an air bag is fixed to the inner bottom of each chute. The water permeable brick has the advantages that rainwater entering the brick body through the water inletdoes not directly permeate into an underwater channel as being blocked by the partition plate but is stored in the brick body in advance, so that the rainwater can be stored to a certain extent, and therefore, accumulated water is supplied to air conveniently after rain stop, and the comfort level of the urban environment is improved; a water flow enters into a water outlet tank when too much accumulated water exits and is further drained to the underwater channel through a water falling pipe, so that normal drainage of the city is guaranteed.

Owner:湖南凯迪工程科技有限公司

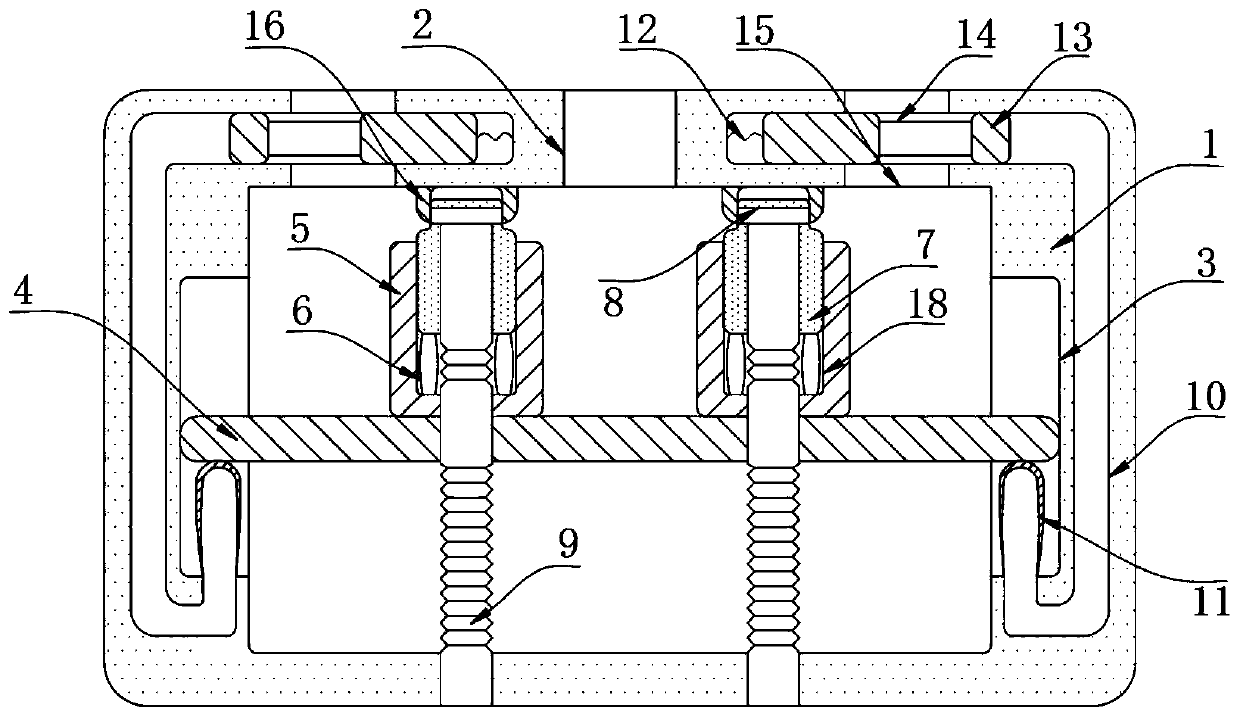

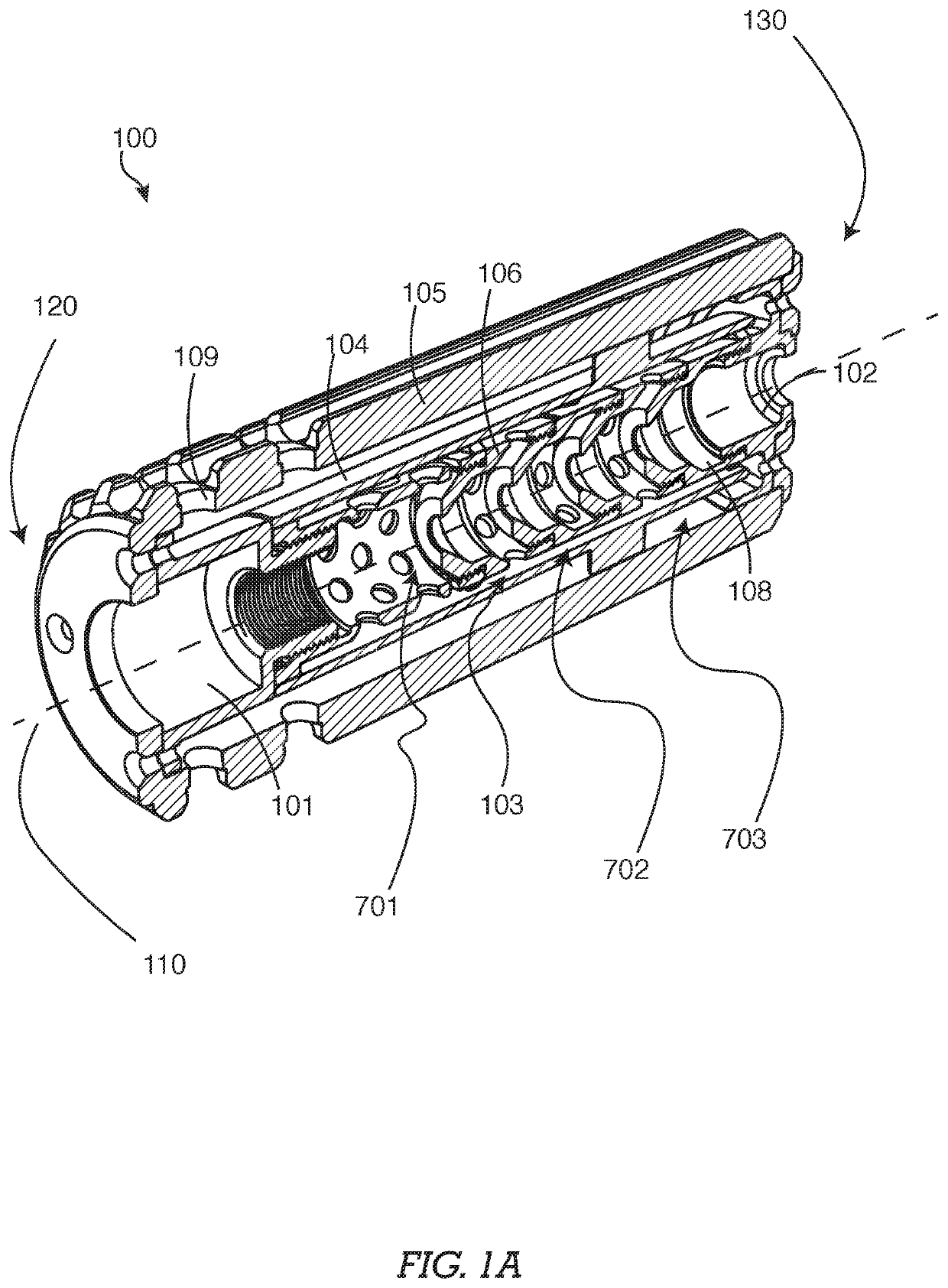

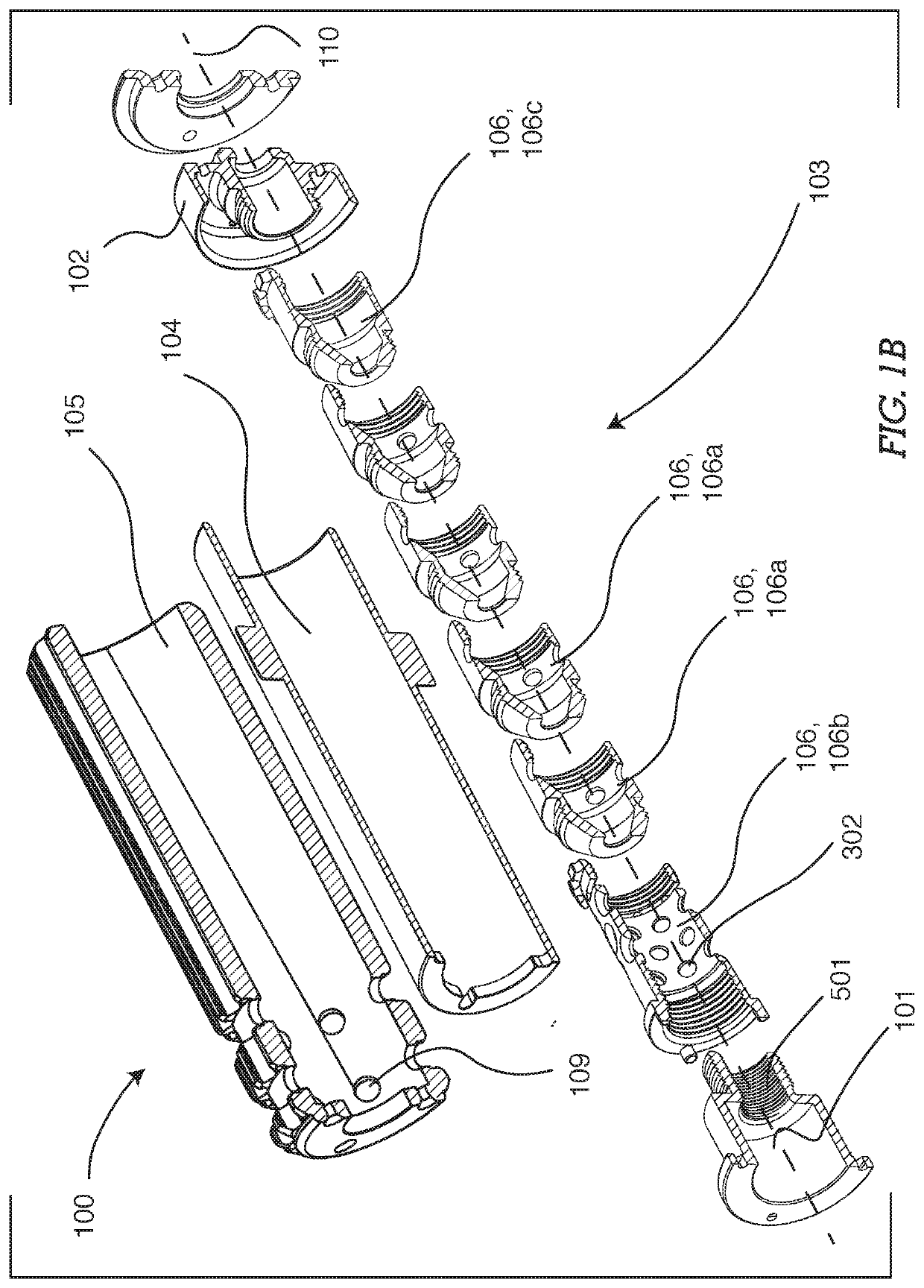

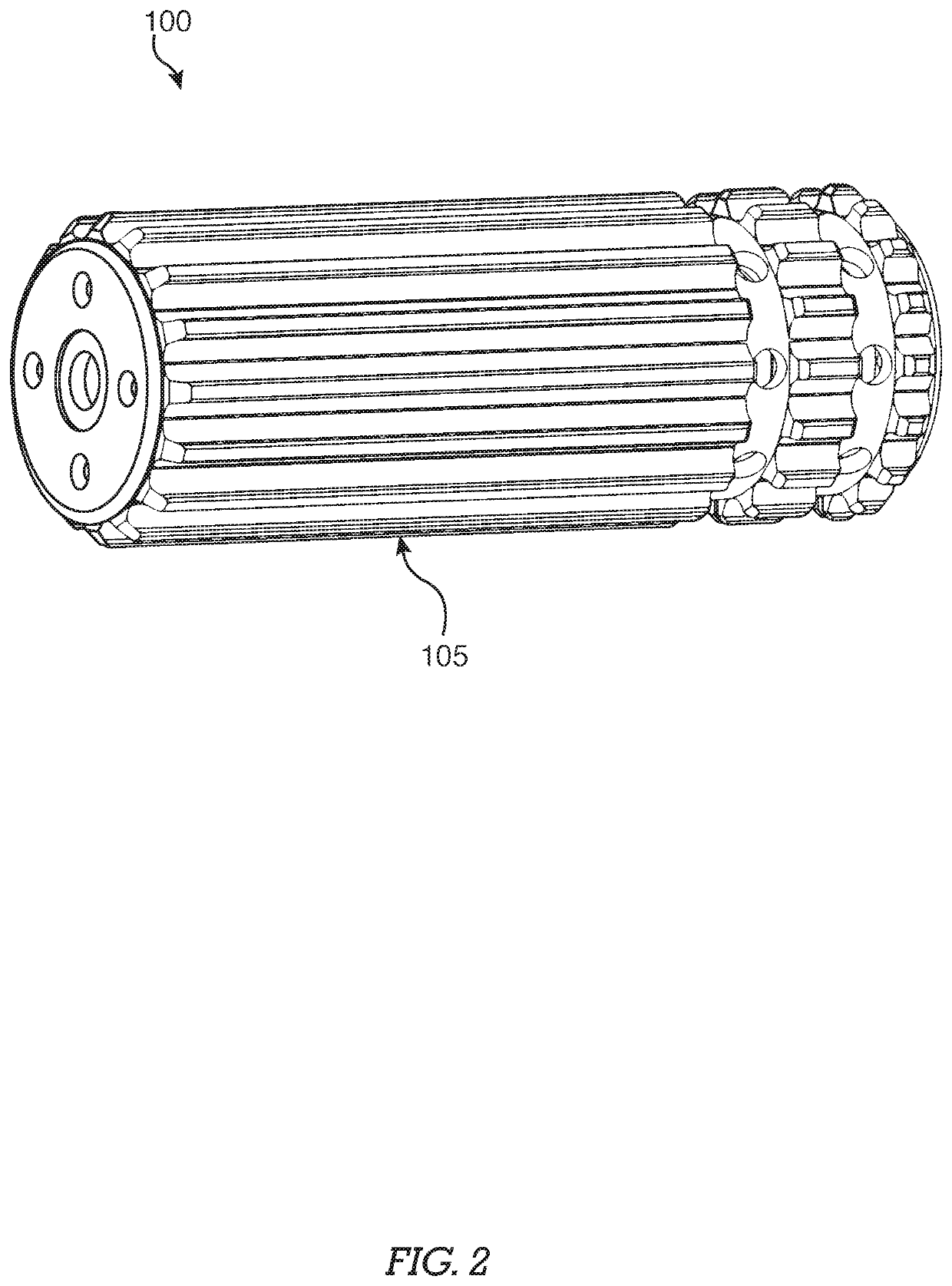

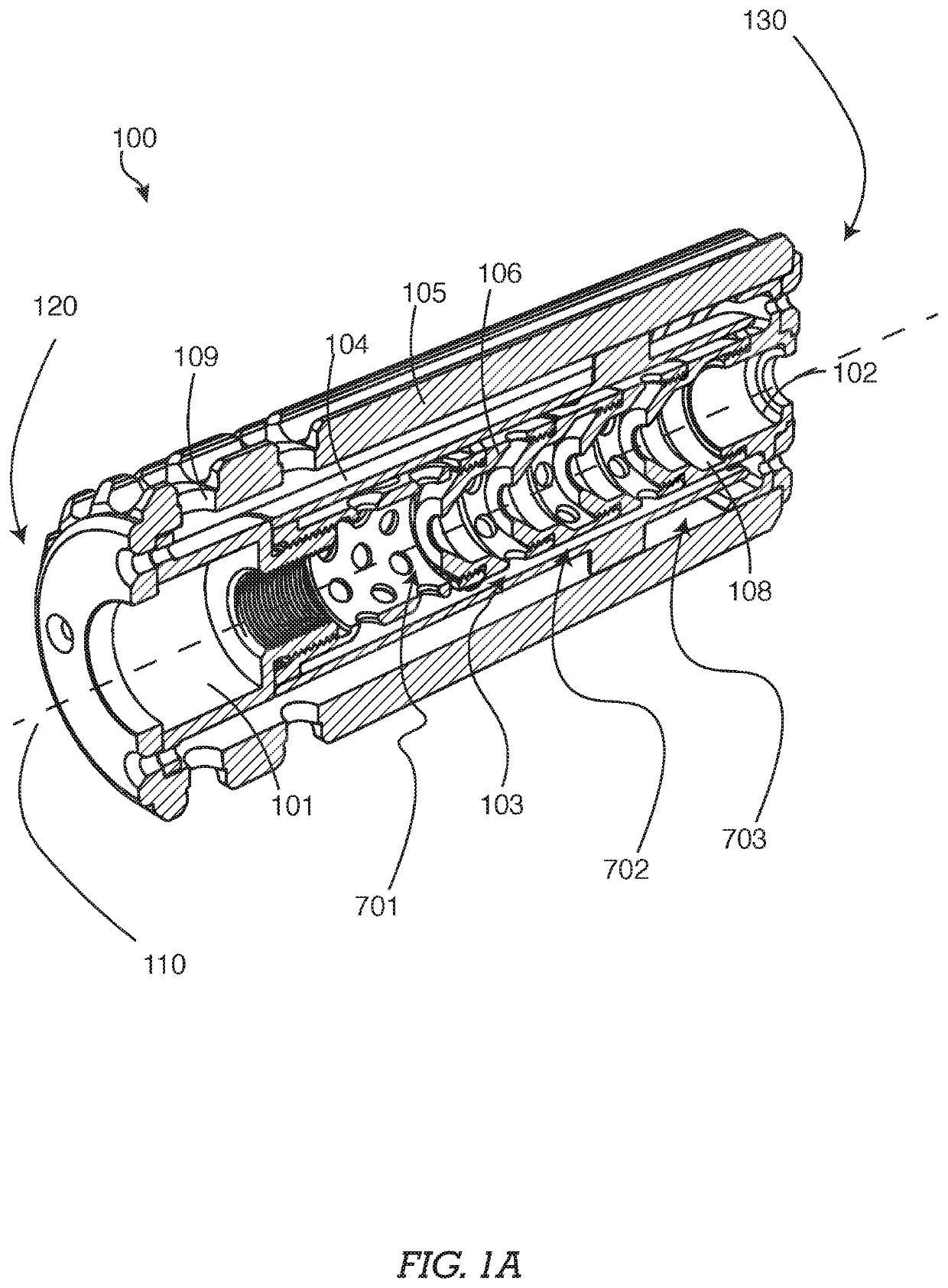

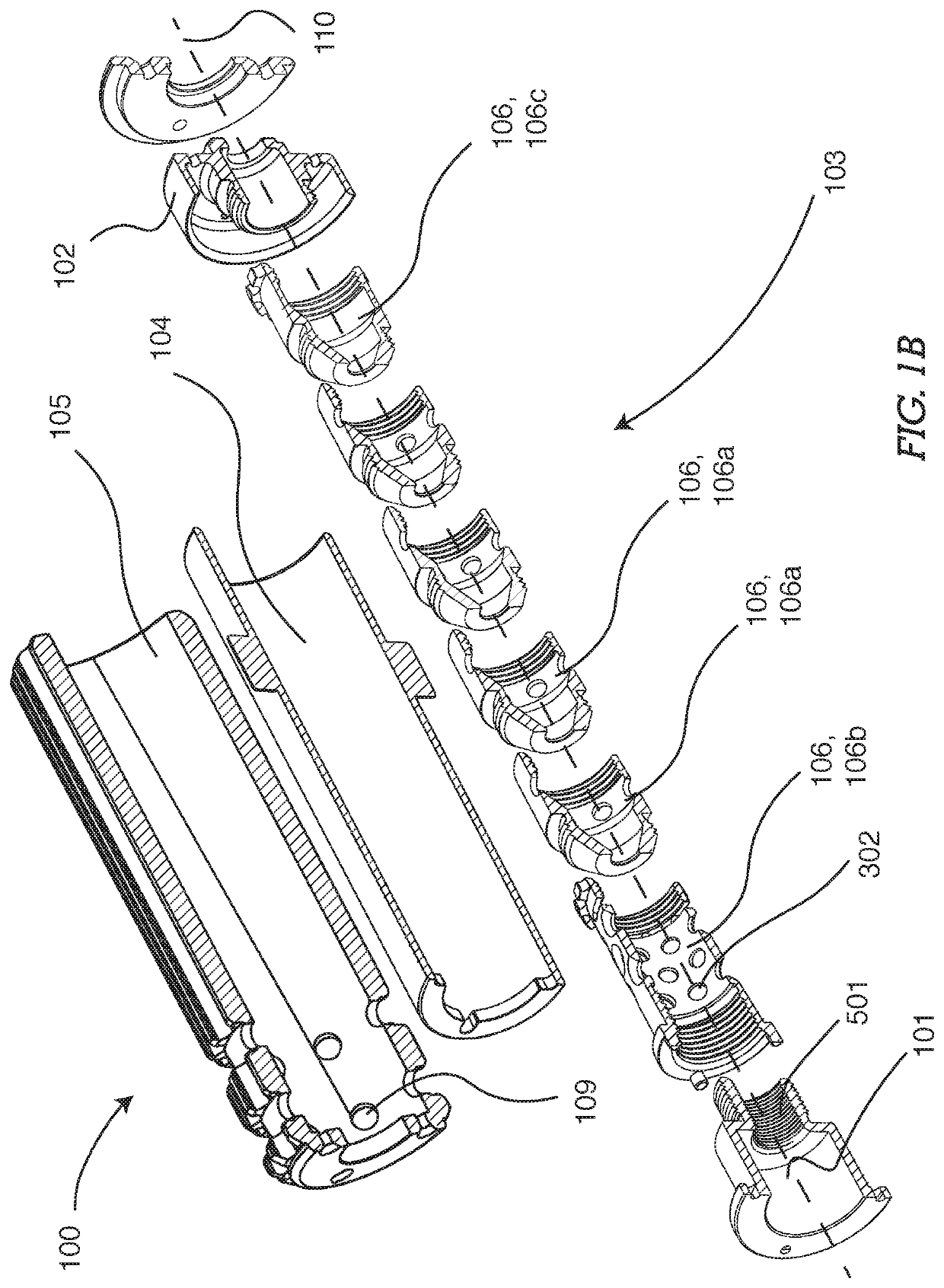

Firearm suppression device

The present invention pertains in general to a suppressing apparatus for the suppression of audible, visible and infrared profiles in the operation of firearms and weapon systems. Embodiments of the invention include the use of a substantially cylindrical component having a helical opening for the dispersion of gasses in conjunction with channels and volumes configured to carry the gasses along the length of the suppressing apparatus toward a distal aspect and toward a proximal aspect alternatively.

Owner:ASCENDANCE INT LLC

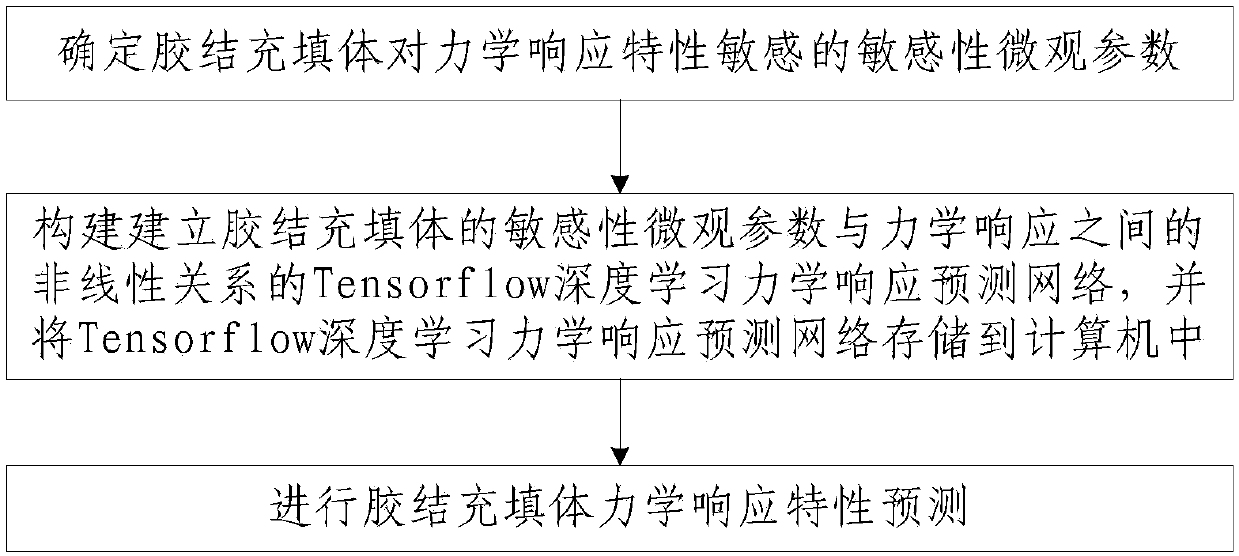

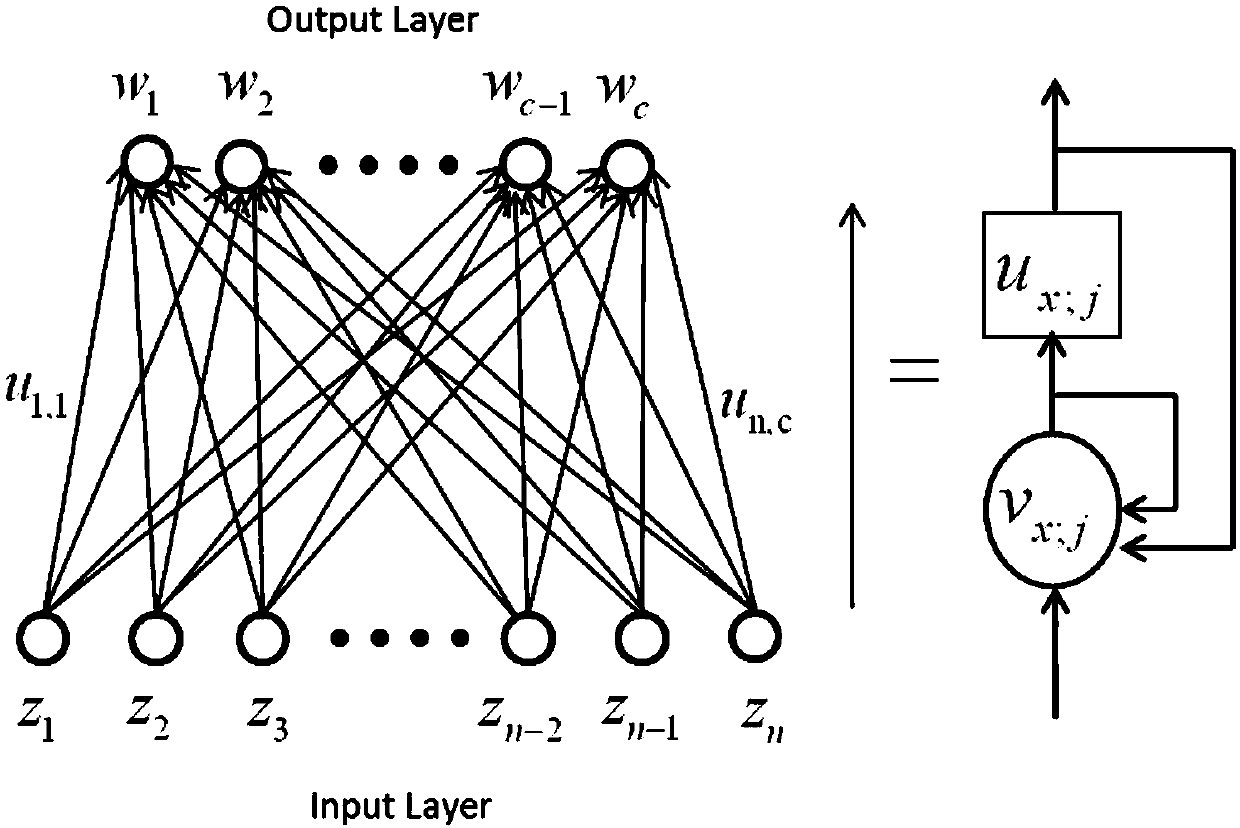

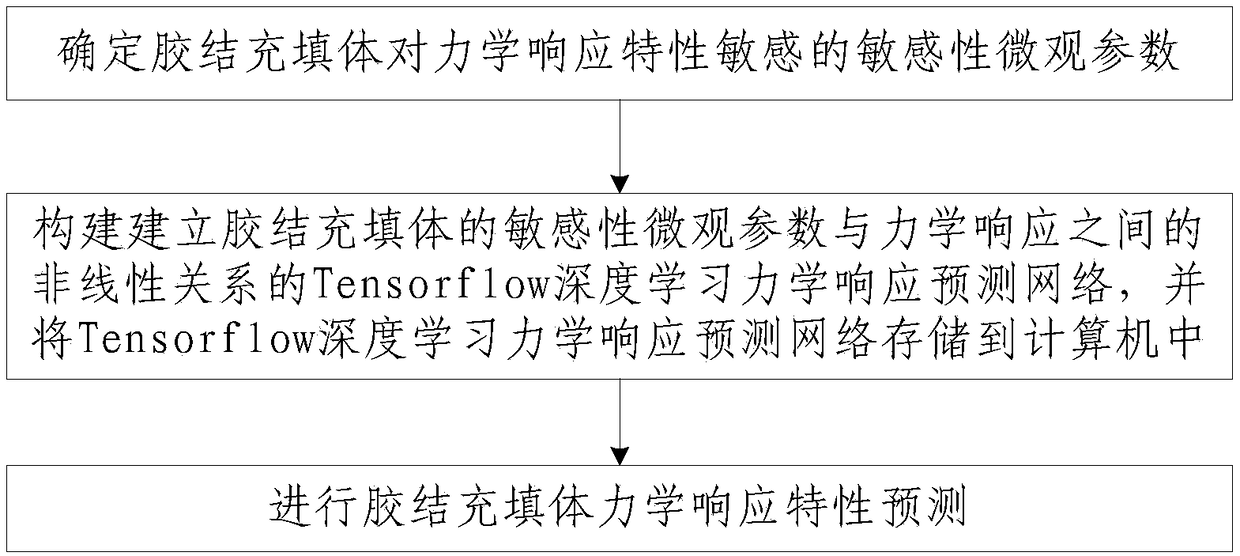

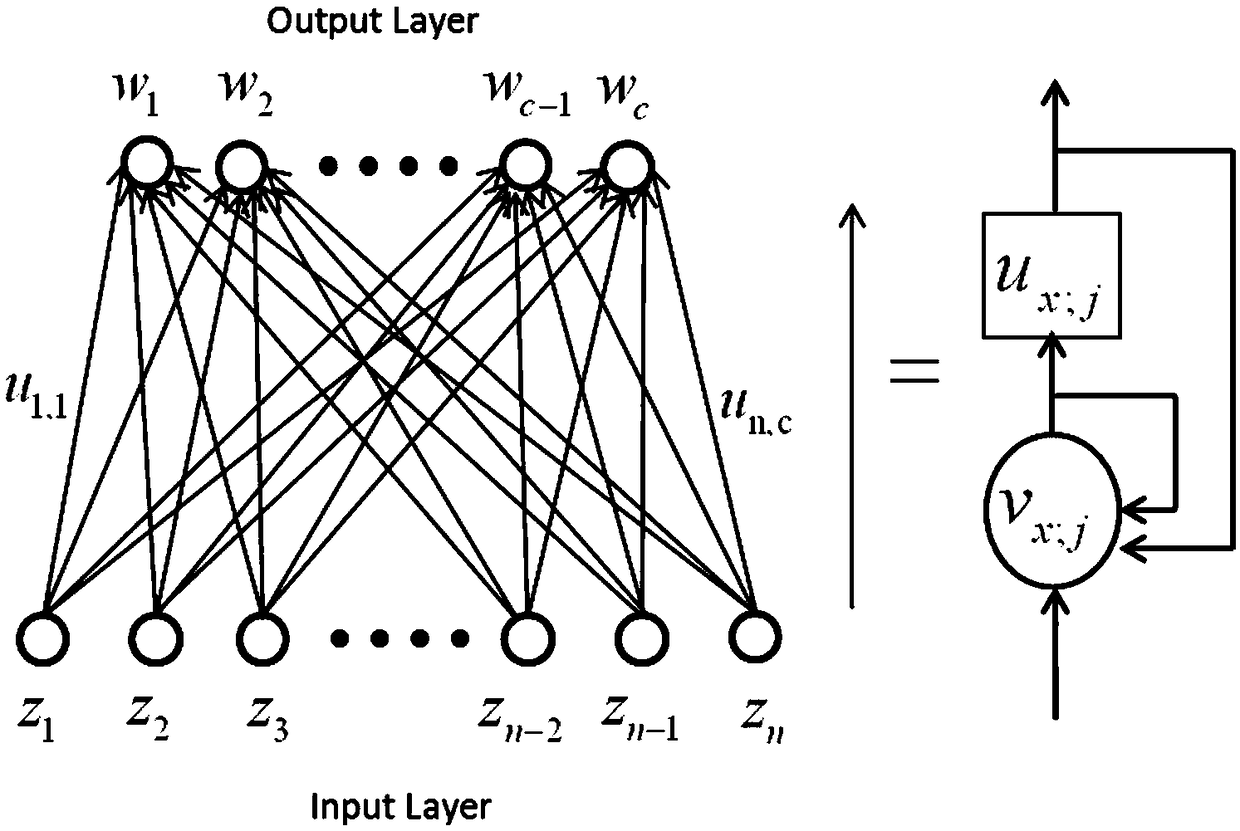

Method for predicting mechanical response characteristics of cemented filling mass on basis of sensitive microscopic parameters

ActiveCN108229062ANovel and reasonable designImprove efficiencyBiological neural network modelsCharacter and pattern recognitionMaterial resourcesEngineering

The invention discloses a method for predicting mechanical response characteristics of cemented filling mass on the basis of sensitive microscopic parameters. The method includes the steps of 1), determining the sensitive microscopic parameters of cemented filling mass on sensitivity of the mechanical response characteristics; 2), establishing non-linear Tensorflow deep-learning mechanical response prediction network between the sensitive microscopic parameters of the cemented filling mass and mechanical response and storing the Tensorflow deep-learning mechanical response prediction network into a computer; 3), predicting the mechanical response characteristics of the cemented filling mass. The method is novel and reasonable in design, convenient and rapid in implementation, capable of acquiring accurate prediction results of the mechanical response characteristics, high in prediction efficiency, low in consumption of labor force and material resources, capable of contributing to thestudy of new cemented filling mass, high in practicability, wide in application range and high in popularization value.

Owner:XIAN UNIV OF SCI & TECH

Firearm suppression device

ActiveUS10746491B2Limit heat conductionLimiting exterior touch temperatureWeapon componentsWeapon systemMechanical engineering

The present invention pertains in general to a suppressing apparatus for the suppression of audible, visible and infrared profiles in the operation of firearms and weapon systems. Embodiments of the invention include the use of a substantially cylindrical component having a helical opening for the dispersion of gasses in conjunction with channels and volumes configured to carry the gasses along the length of the suppressing apparatus toward a distal aspect and toward a proximal aspect alternatively.

Owner:ASCENDANCE INT LLC

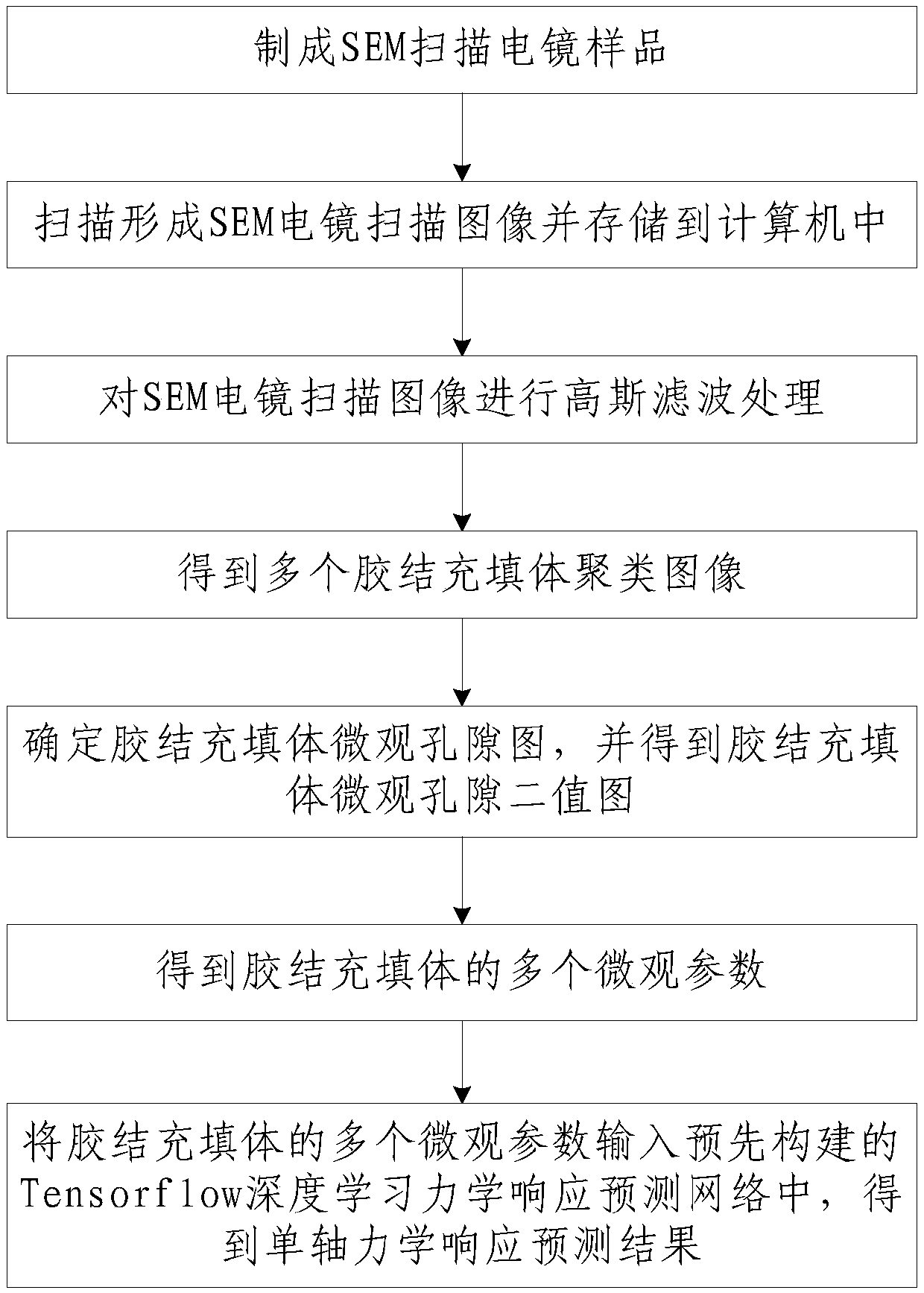

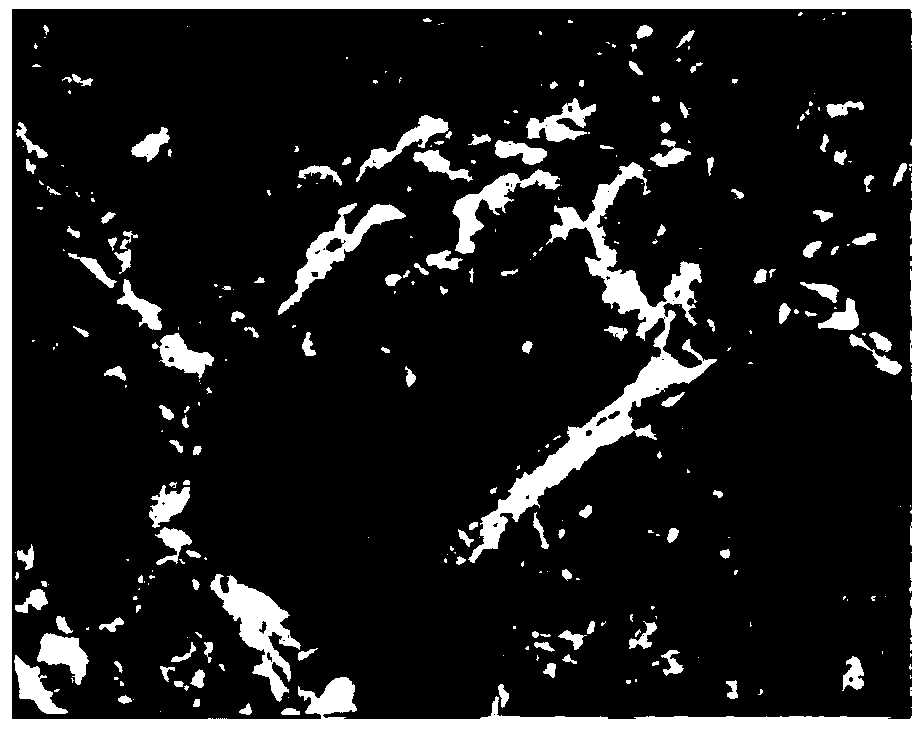

Method for predicating mechanical response characteristic of cemented backfill based on images and microscopic parameters

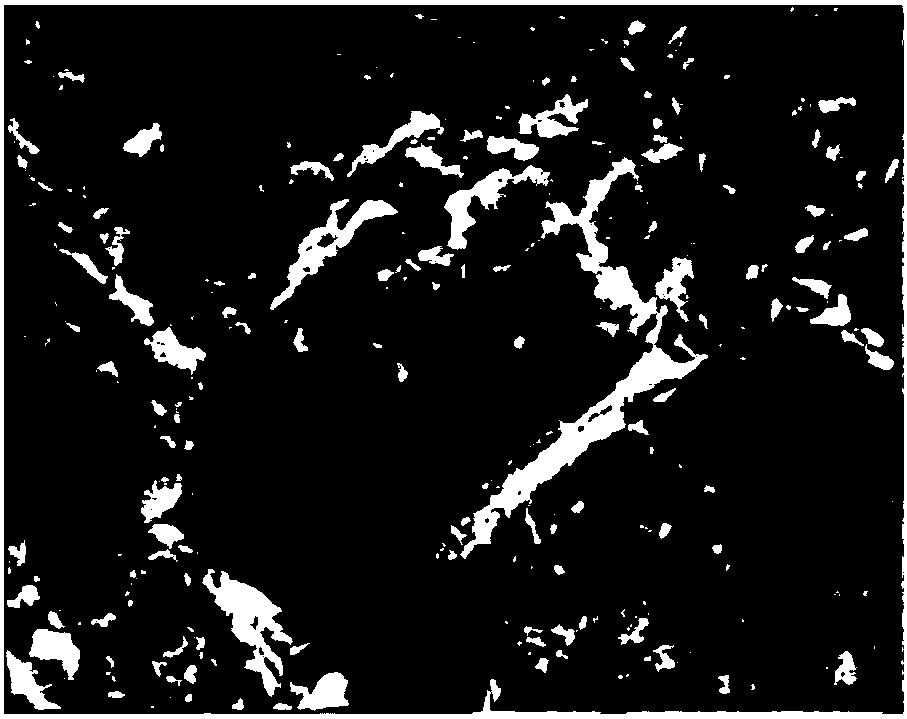

ActiveCN108445030APredicting Mechanical Response PropertiesThe method steps are simpleImage enhancementImage analysisScanning electron microscopeMaterial resources

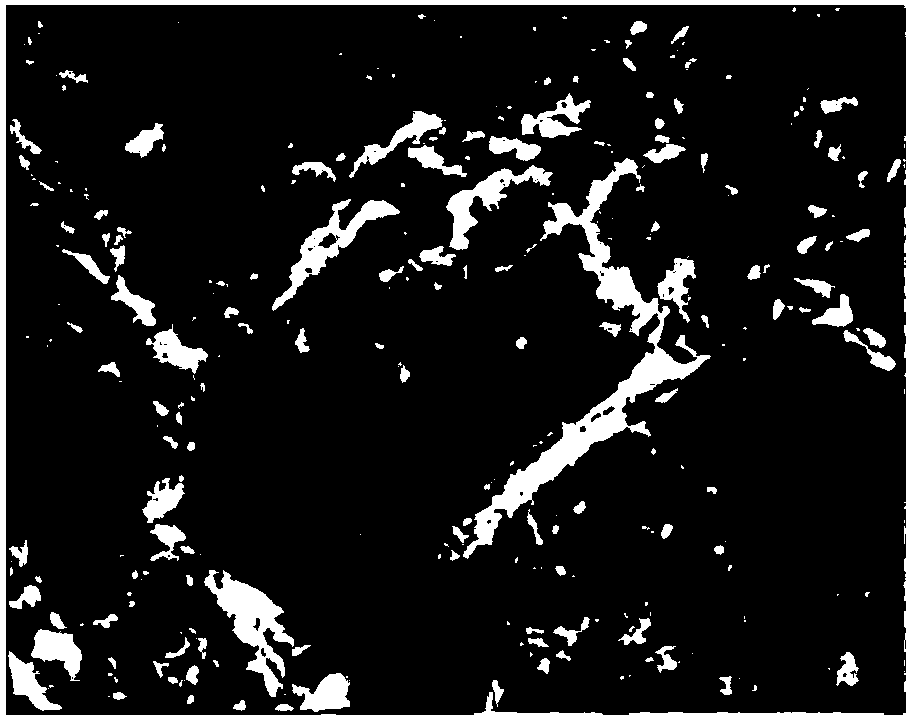

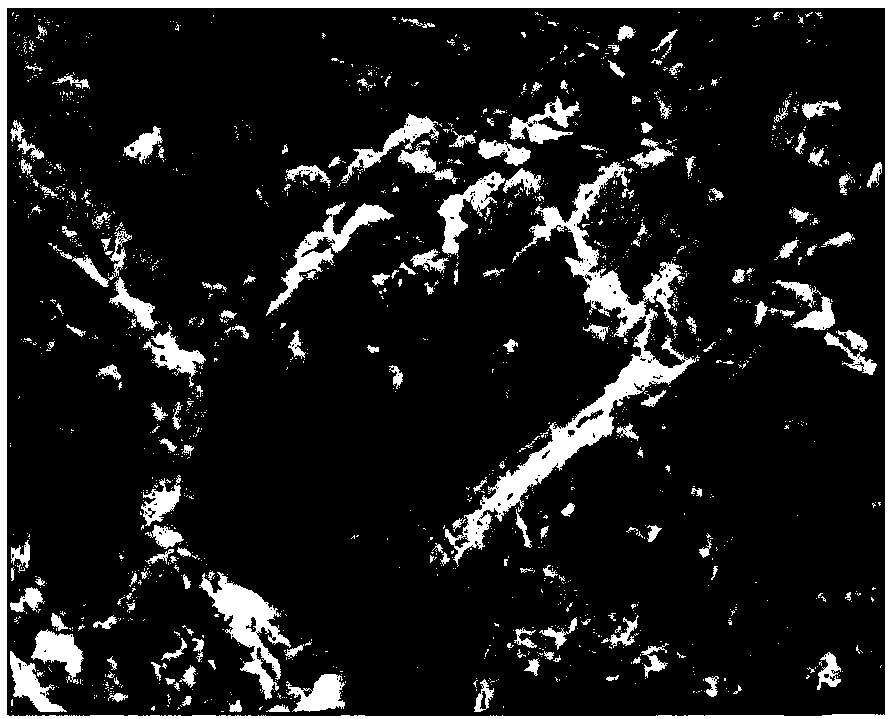

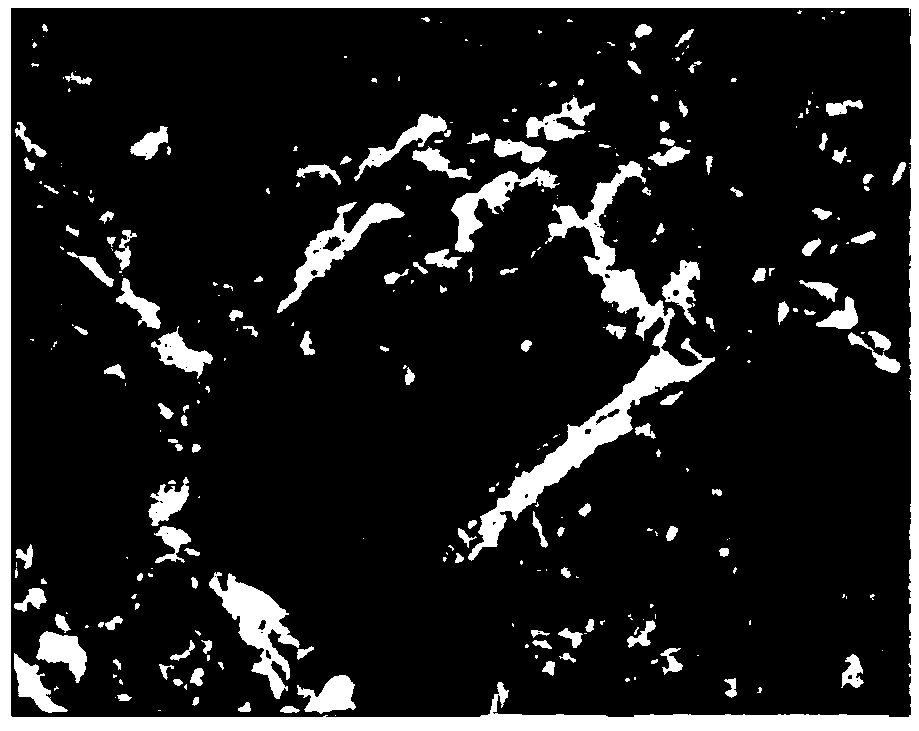

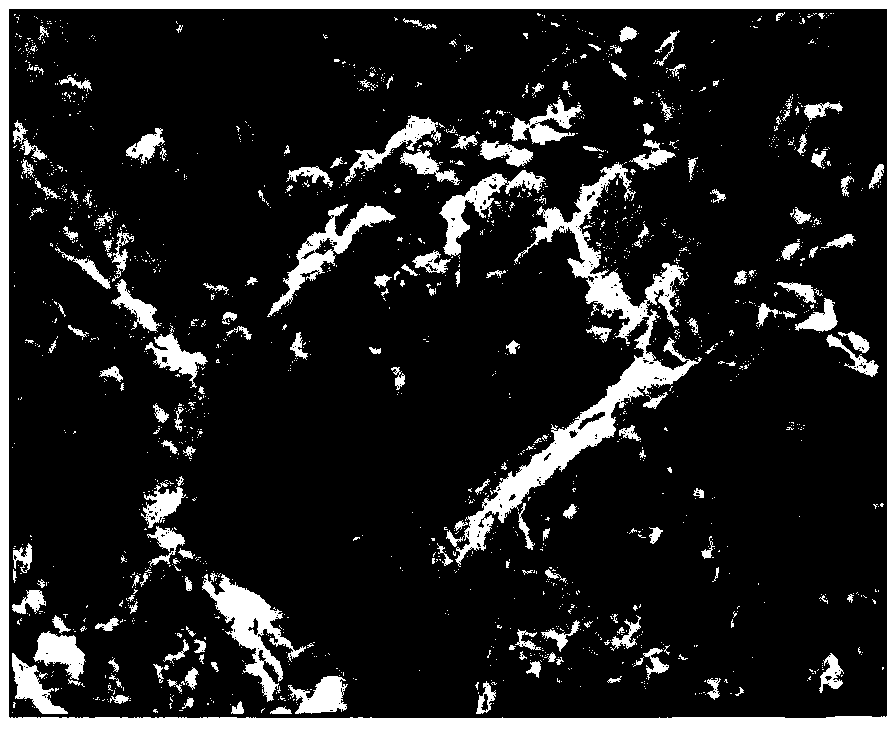

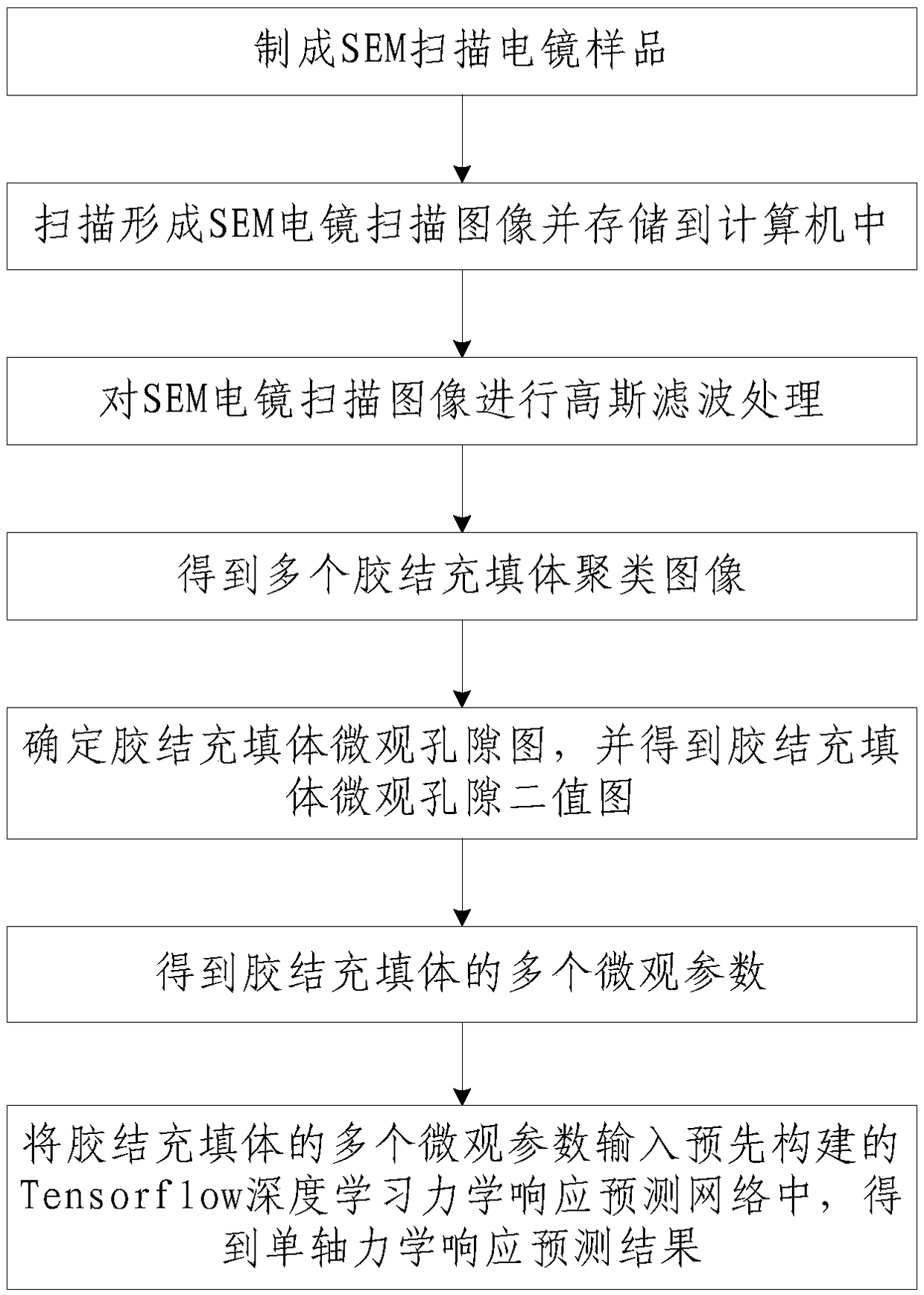

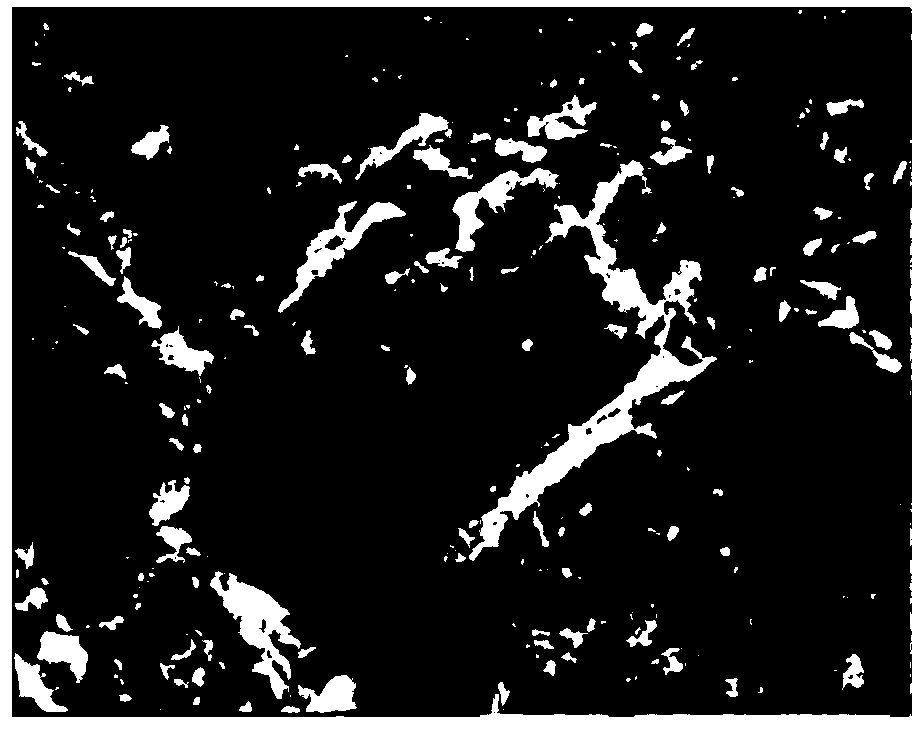

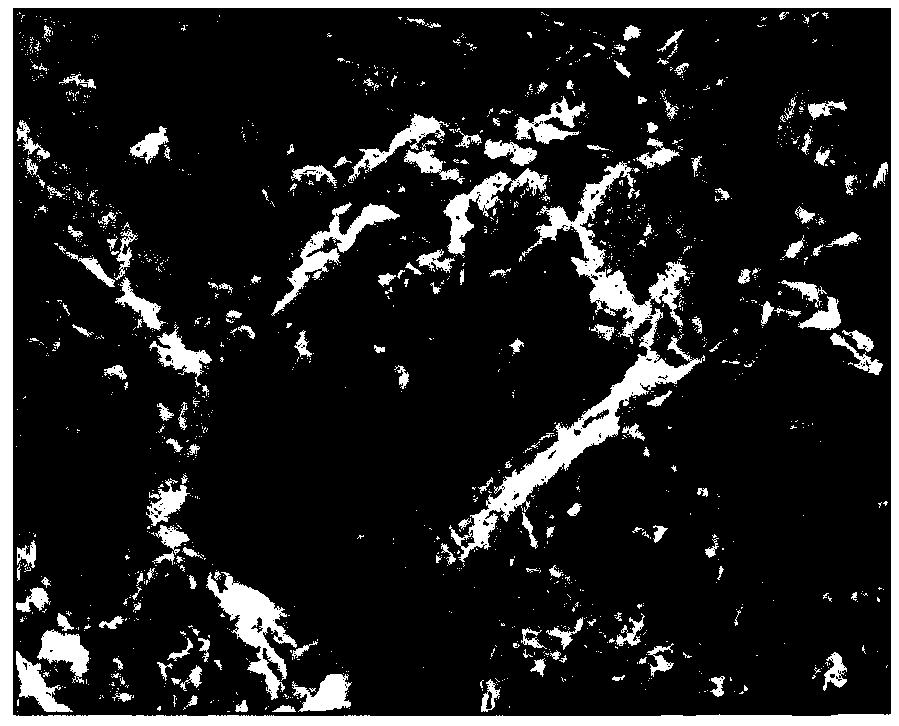

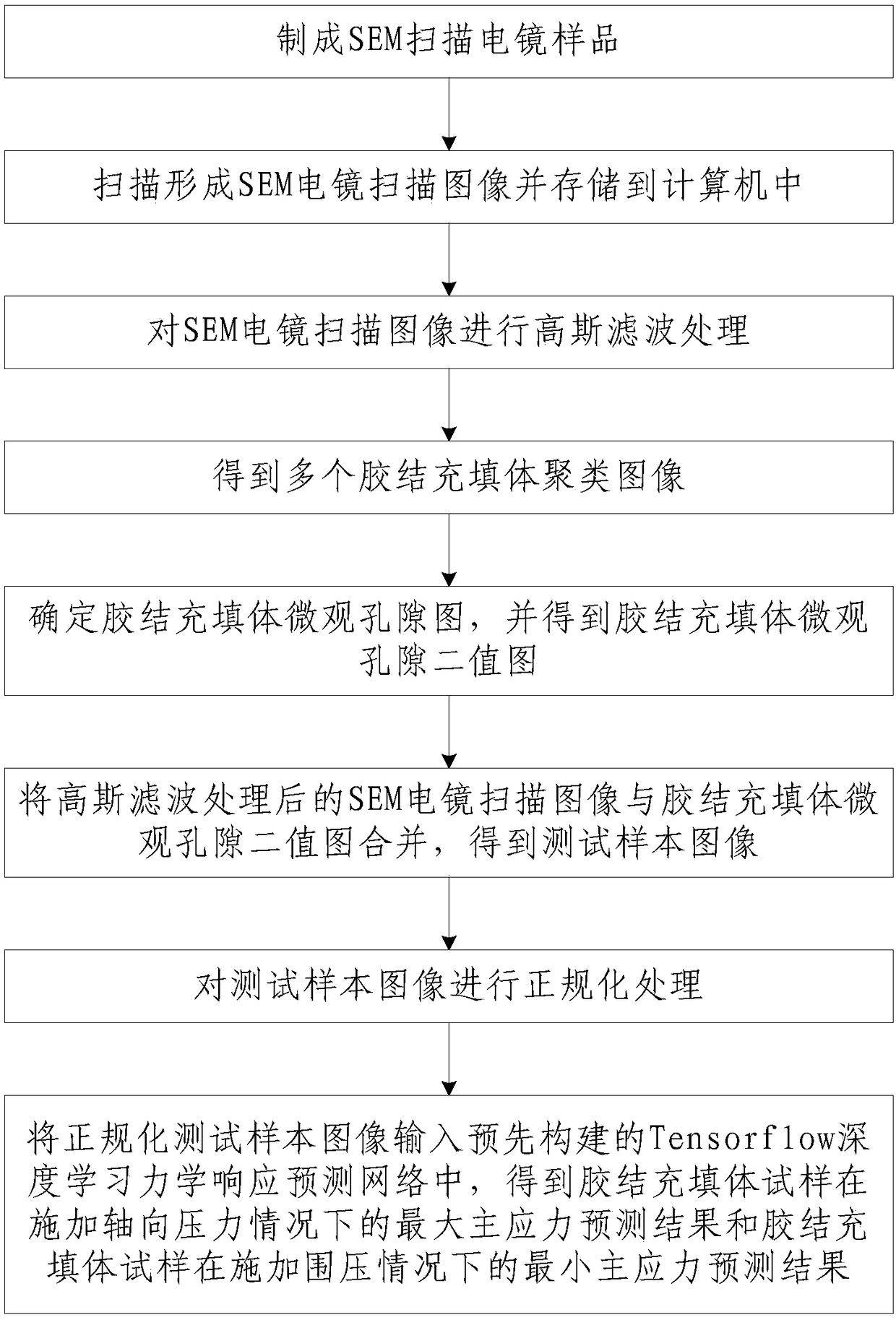

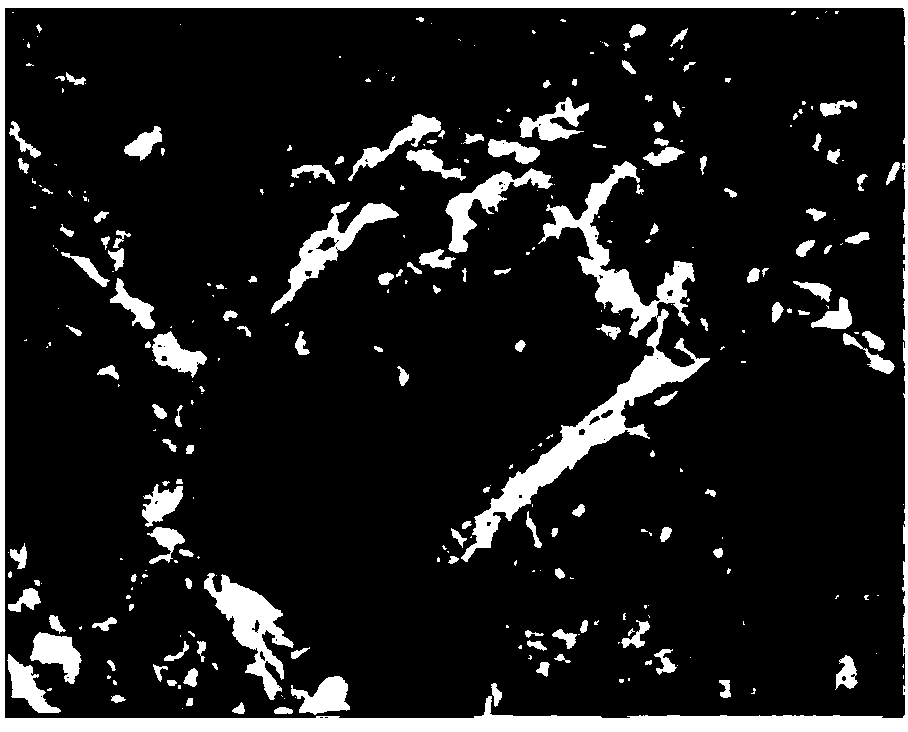

The invention discloses a method for predicating the mechanical response characteristic of a cemented backfill based on images and microscopic parameters. The method comprises the following steps: 1,preparing an SEM (scanning electron microscope) sample; 2, performing scanning to form an SEM scanning image, and storing the SEM scanning image in a computer; 3, performing Gaussian filtering processing on the SEM scanning image; 4, obtaining multiple cluster images of the cemented backfill; 5, determining the microscopic pore map of the cemented backfill to obtain a microscopic pore binary imageof the cemented backfill; 6, analyzing and processing the microscopic pore binary image of the cemented backfill to obtain multiple microscopic parameters of the cemented backfill; and 7, inputting the multiple microscopic parameters of the cemented backfill into a pre-built Tensorflow deep learning mechanical response prediction network, and obtaining a uniaxial mechanical response prediction result. The method has the advantages of high prediction efficiency, high prediction precision, low consumption of manpower and material resources, great values in studying the strength and the stability of the cemented backfill, strong practicability and high promotion and application values.

Owner:XIAN UNIV OF SCI & TECH

Water-borne antirust coating having good heat dissipation and applied to pump valve

InactiveCN105462378AImprove stabilityImprove permeabilityAnti-corrosive paintsPhosphateMechanical property

The invention discloses a water-borne antirust coating having good heat dissipation and applied to a pump valve. The water-borne antirust coating is prepared from raw materials in parts by weight as follows: 65-70 parts of methyl methacrylate, 60-65 parts of styrene, 0.5-0.6 parts of ammonium persulfate, 4-5 parts of phosphate ester monomers, 20-24 parts of deionized water, 2-3 parts of SDS (sodium dodecyl sulfate), 35-40 parts of glass flakes, 1-1.2 parts of a silane coupling agent KH560, 30-35 parts of an ethanol solution with the concentration of 75wt%, 40-43 parts of a sodium hydroxide solution with the concentration of 10wt%, 2-3 parts of isopropanol, 3-4 parts of catechol, 0.7-0.8 parts of alkylphenol polyoxyethylene alcohol, 3-4 parts of zinc phosphate, 12-14 parts of aluminum nitride, 3-4 parts of heat conducting silicone grease, 10-12 parts of zinc oxide, 1.5-2 parts of dimethicone and proper amount of water. The prepared coating can release high temperature caused by work after being sprayed to the surface of a pump valve material and has excellent heat dissipation effect and mechanical properties, and the service life is prolonged.

Owner:TONGLING SIDE TECH

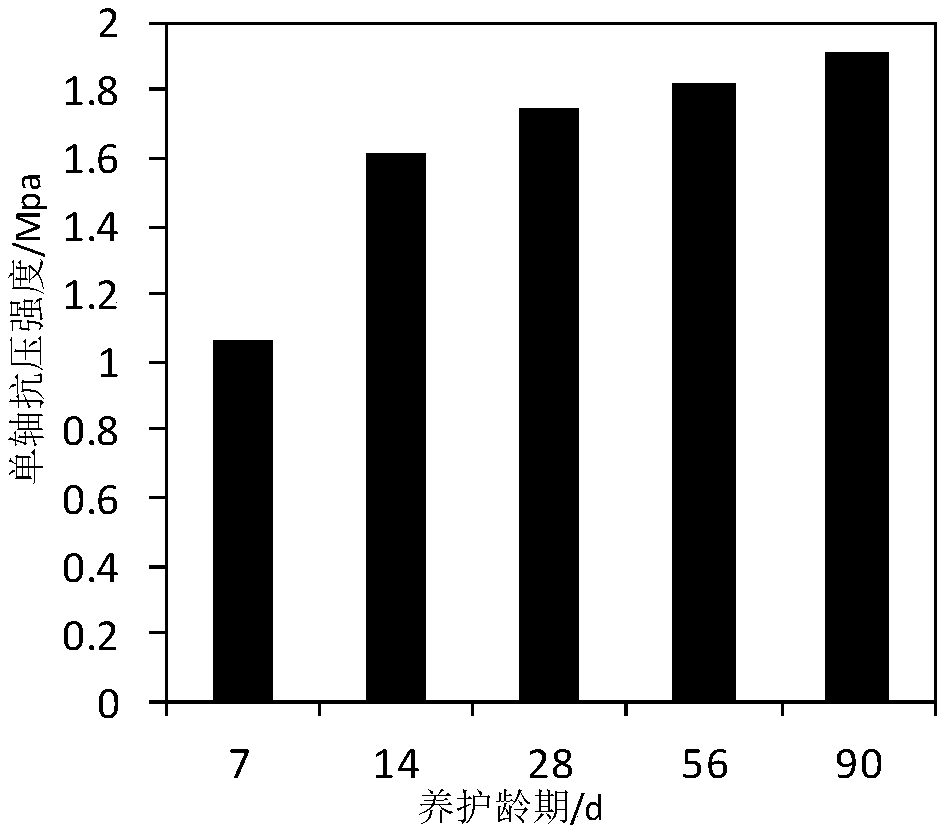

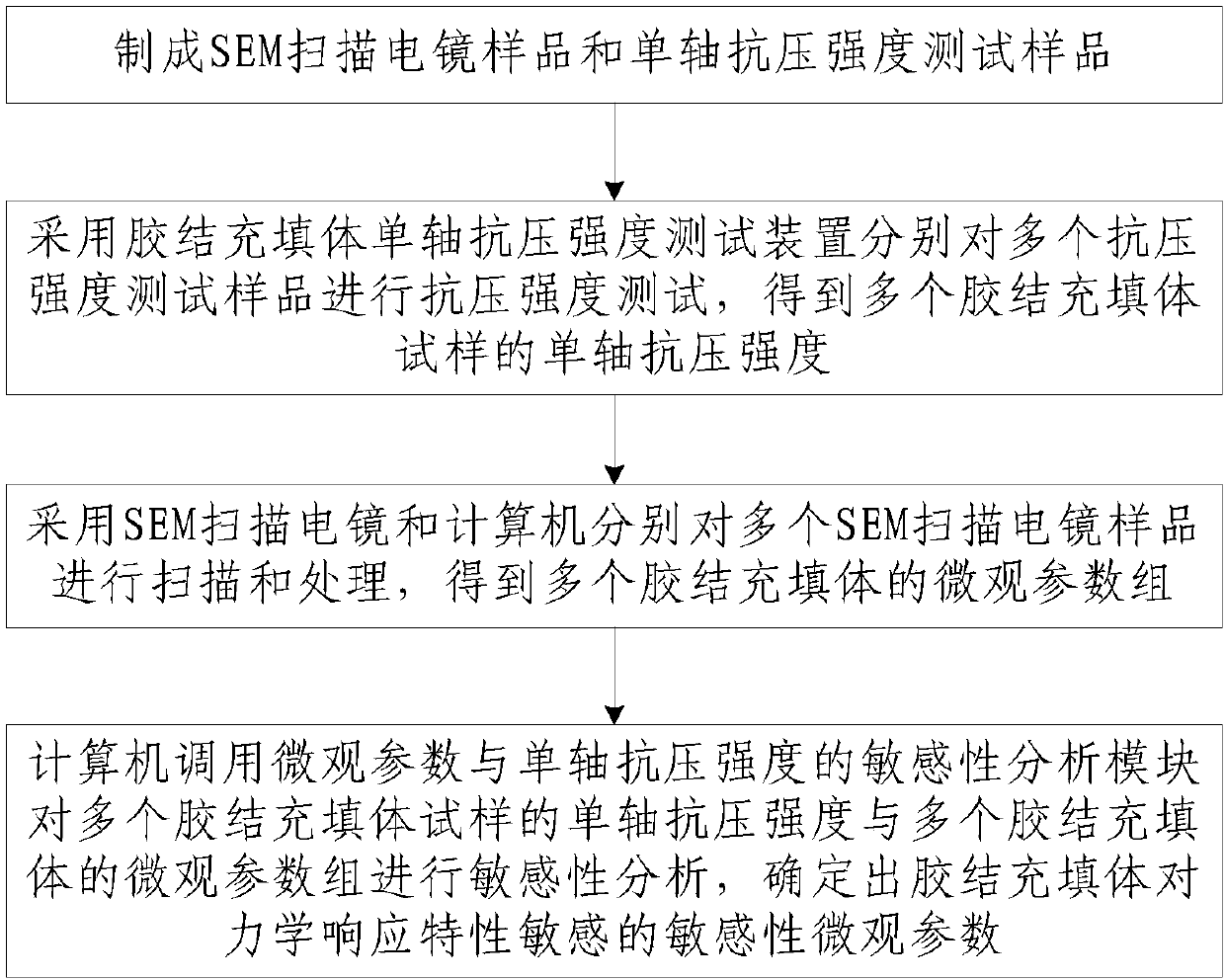

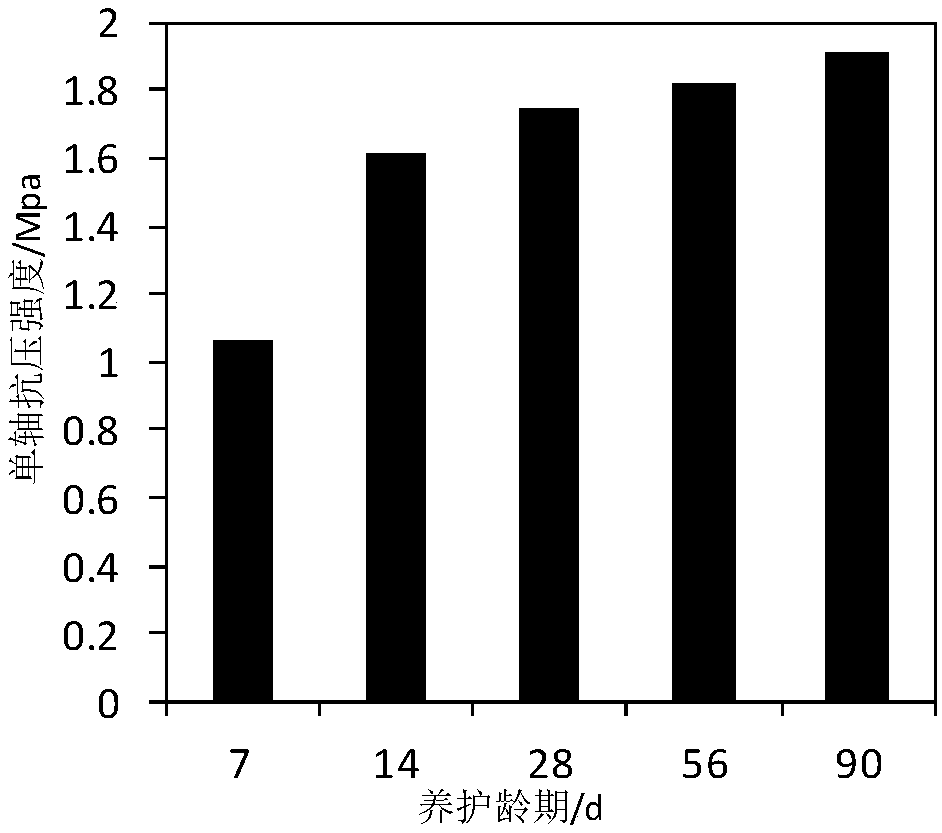

Cemented backfill microscopic parameter sensitivity analysis method based on image processing

ActiveCN108287254AThe method steps are simpleNovel and reasonable designMaterial strength using tensile/compressive forcesScanning probe techniquesImaging processingSensitive analysis

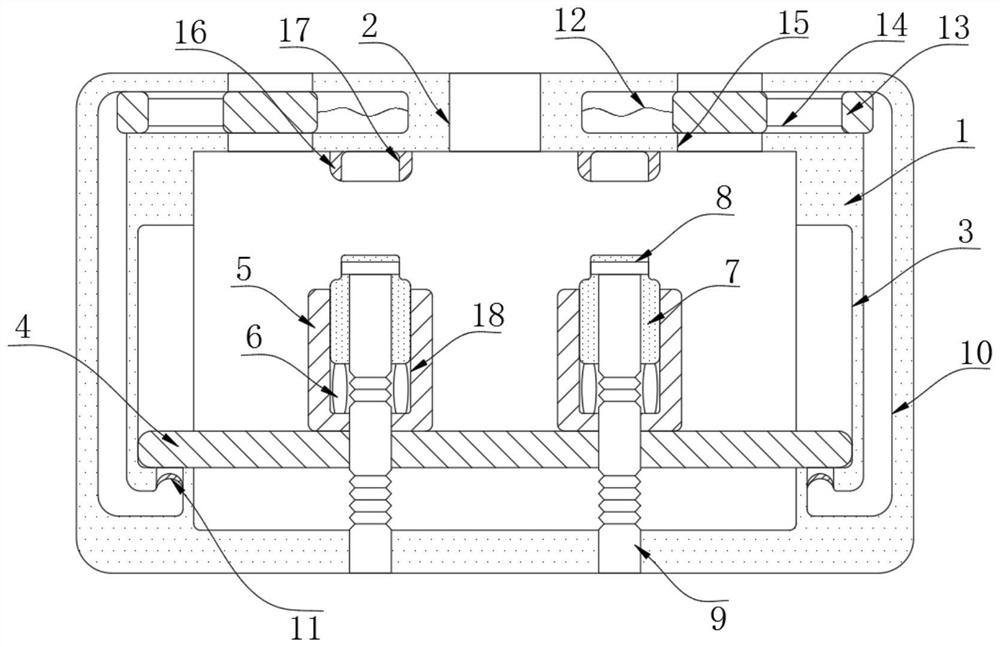

The invention discloses a cemented backfill microscopic parameter sensitivity analysis method based on image processing. The method comprises the steps of 1, preparing an SEM scanning electron microscope sample and a single-axis compressive strength testing sample; 2, performing single-axis compressive strength testing on a plurality of compressive strength testing samples by means of a cemented backfill single-axis compressive strength testing device, and obtaining the single-axis compressive strength of a plurality of cemented backfill samples; 3, obtaining a microscopic parameter set of theplurality of cemented backfills; and 4, calling the microscopic parameter and a sensitivity analysis module for the single-axis compressive strength for performing sensitivity analysis on the single-axis compressive strength of the plurality of cemented backfill samples and the microscopic parameter set of the plurality of cemented backfills, and determining the sensitivity microscopic parameterof the cemented backfill to mechanical response characteristic sensitivity. The method can well determine a primary and secondary relation of the microscopic parameters and can help in researching a new cemented backfill.

Owner:XIAN UNIV OF SCI & TECH

Medicinal composition for treating livestock and poultry cold, preparation method thereof and application thereof

InactiveCN101695490APromote pituitary hormone secretionActivate pancreas functionAntiviralsAnhydride/acid/halide active ingredientsBreathingAdjuvant

The invention discloses a medicinal composition for treating livestock and poultry cold, a preparation method thereof and application thereof and aims to provide the medicinal composition for effectively preventing and controlling the livestock and poultry cold, the preparation method thereof and the application thereof. The medicinal composition for treating the livestock and poultry cold comprises the following components in percentage by weight: 10 to 30 percent of paracetamol, 0.1 to 0.5 percent of chlorpheniramine maleate, 3 to 10 percent of taurine, and the balance of pharmaceutically acceptable adjuvant. When livestock and poultry catch cold, the medicinal composition for treating the livestock and poultry cold quickly relieves poultry hyperthermia, improves enhance resistance and effectively relieves reduced appetite, quickened breath, death and the like of the livestock and poultry caused by livestock and poultry influenza. The medicinal composition can improve laying rate and egg weight, improve daily average feed intake, improve feed conversion rate, alleviate laying peak descending process and reduce egg breakage rate. The medicinal composition can reduce comb temperature, body temperature and breathing rate shortening course of disease of heat stress layer chicken.

Owner:TIANJIN SHENGJI GRP CO LTD

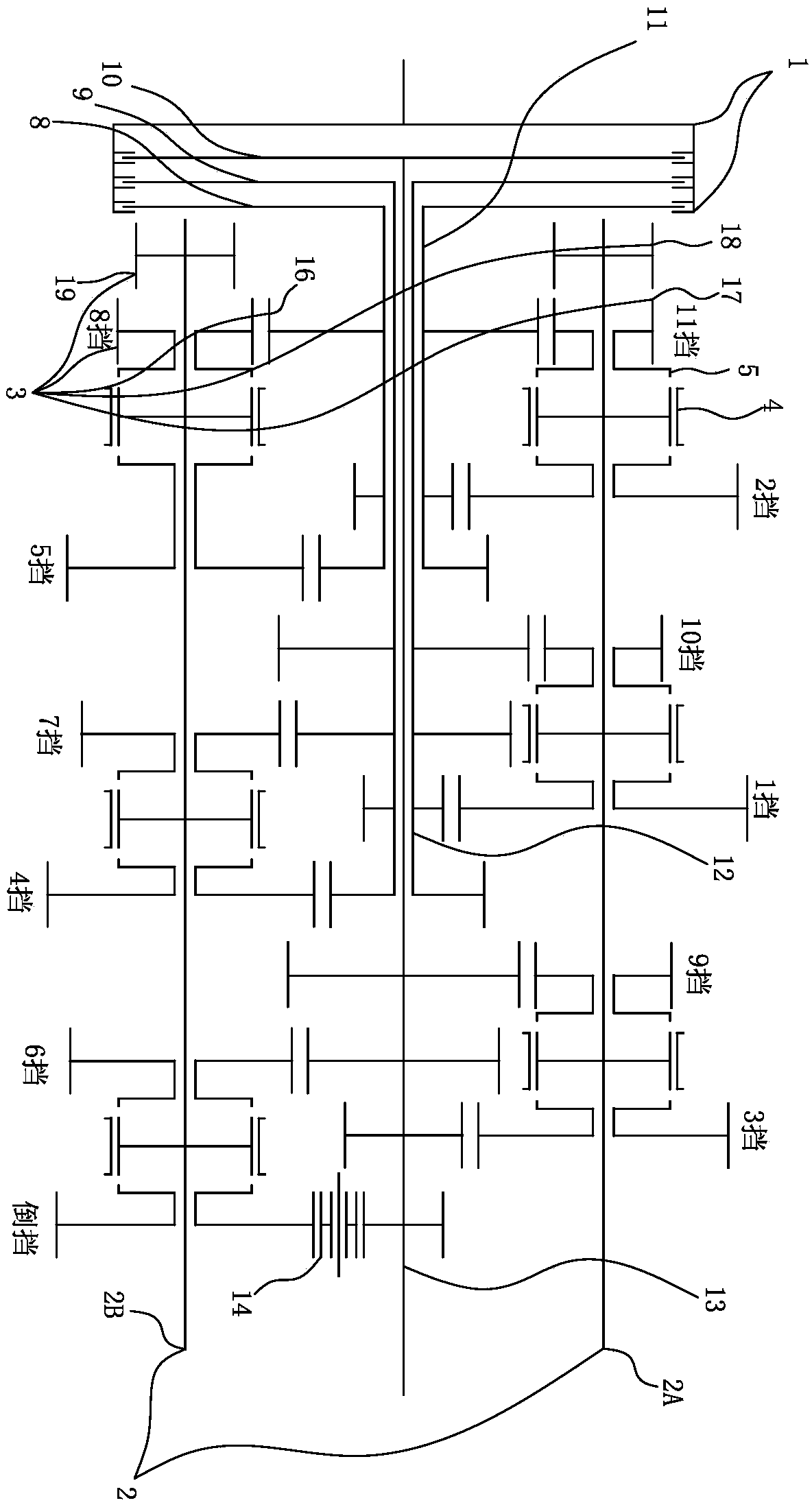

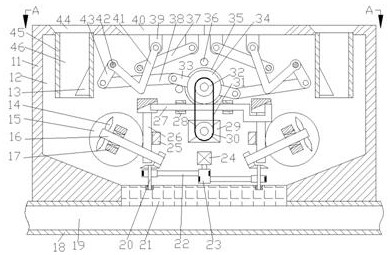

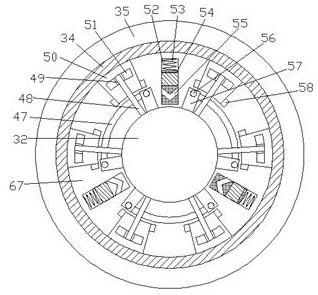

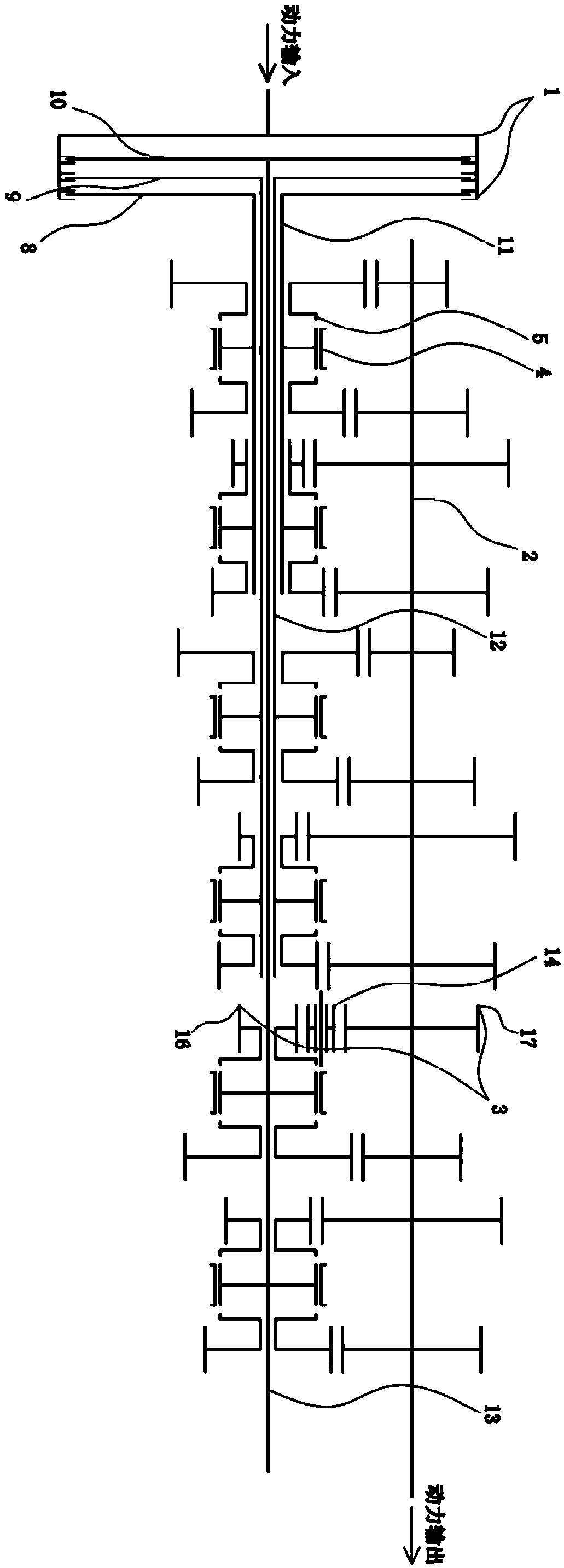

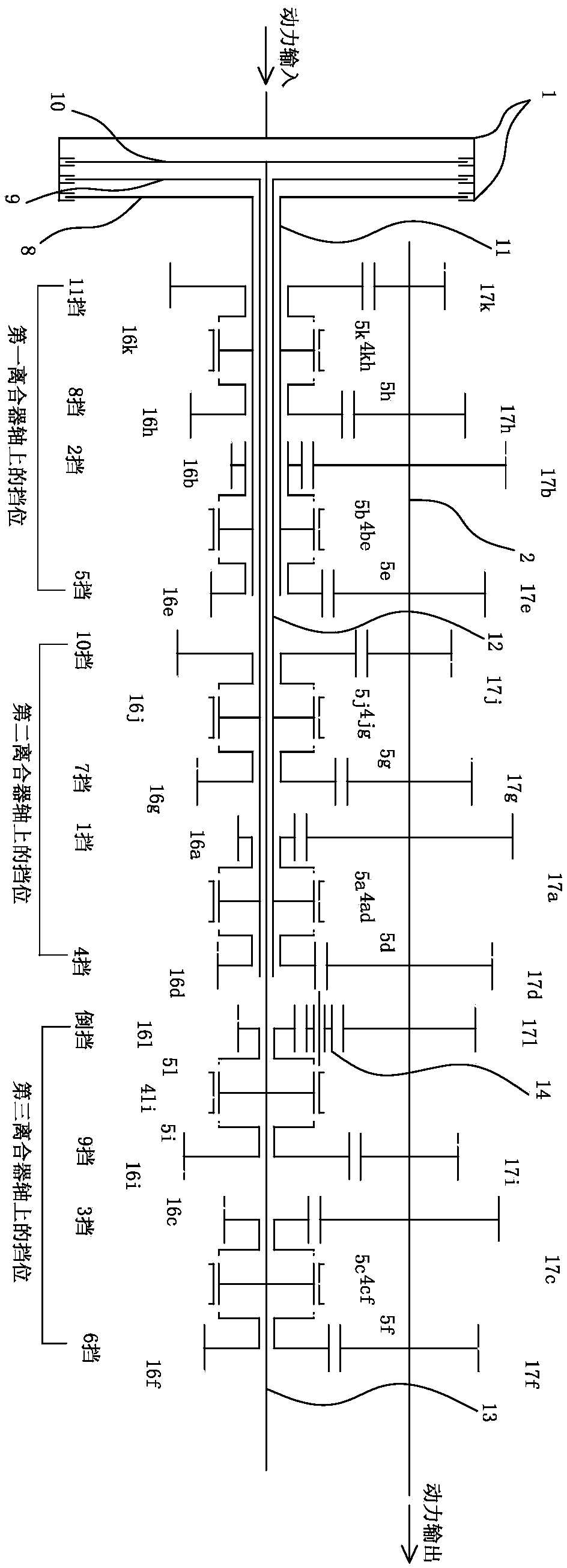

Triple-clutch parallel-shaft-output automatic transmission

InactiveCN108869647ARelieve high temperatureReduce wear and tearToothed gearingsAutomatic transmissionGear wheel

A triple-clutch parallel-shaft-output automatic transmission comprises a clutch, a transmission output shaft, transmission gears, a coupling device and a coupler. The clutch includes three clutches, namely, first clutch, a second clutch and a third clutch; the distribution of the transmission gears on the three clutch shafts feature: in addition to a lowest gear, a highest gear and a reverse gear,each working gear of each clutch shaft having two a prepared gear ratio mounted on another two clutch shafts respectively, wherein the other prepared gear is one prepared gear lower than the workinggear. The triple-clutch parallel-shaft-output automatic transmission has the advantages that shift delay as in dual-clutch transmissions is avoided; in case of road jamming, high heat and abrasion ofthe clutches can be relieved; the transmission herein employing the parallel shaft output structural form has short length and can meet the requirement of front-engine automobiles for transmission length.

Owner:陈学琴

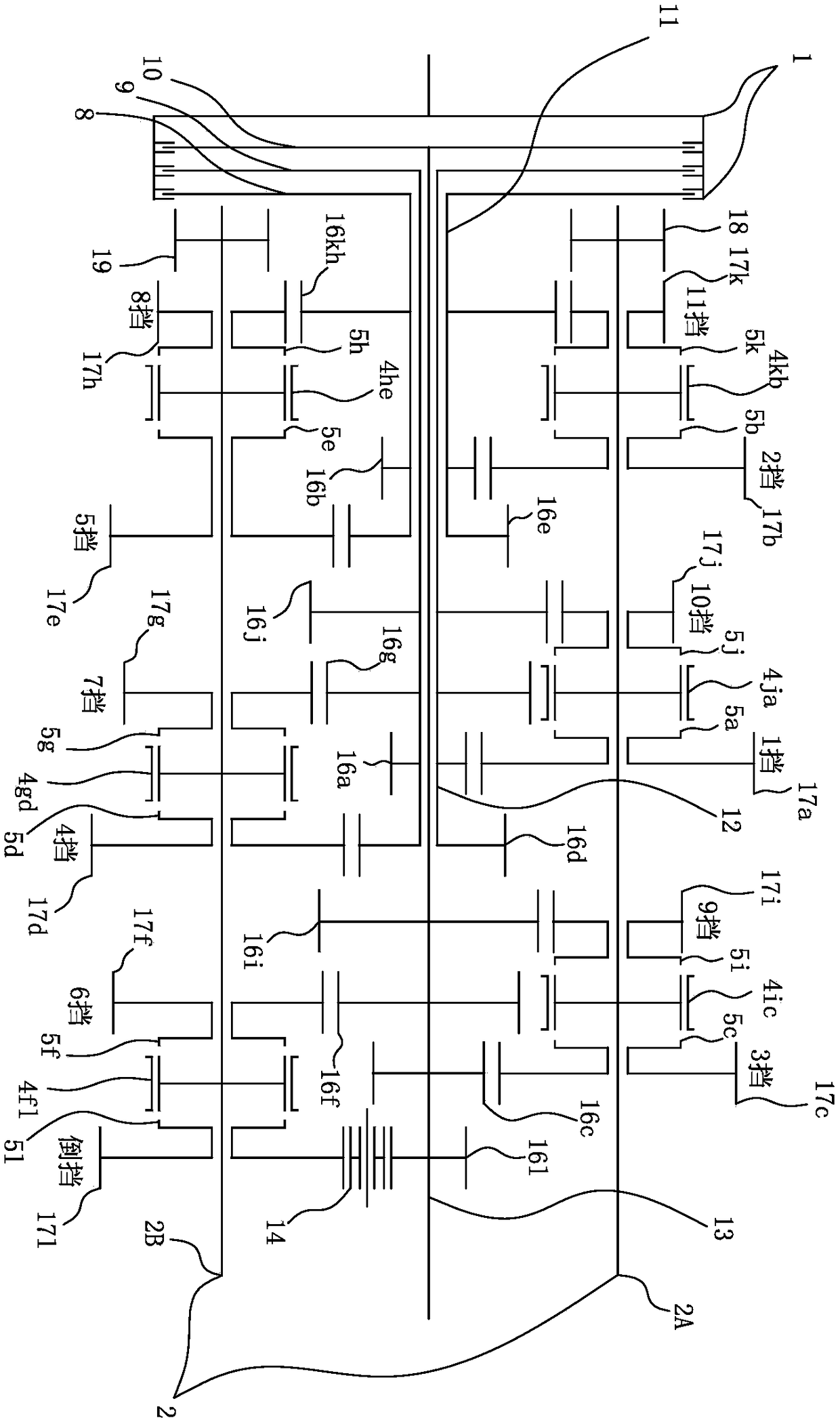

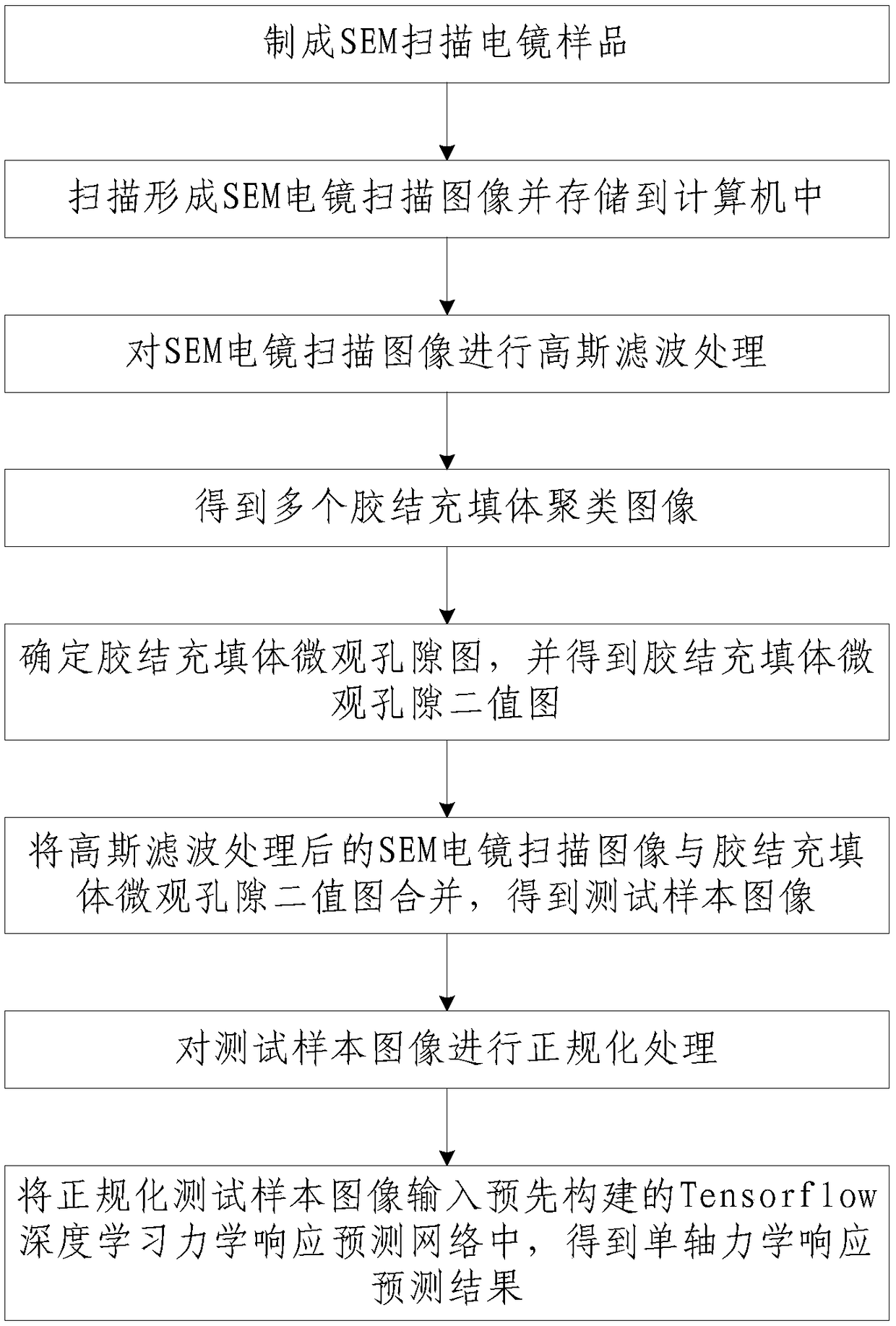

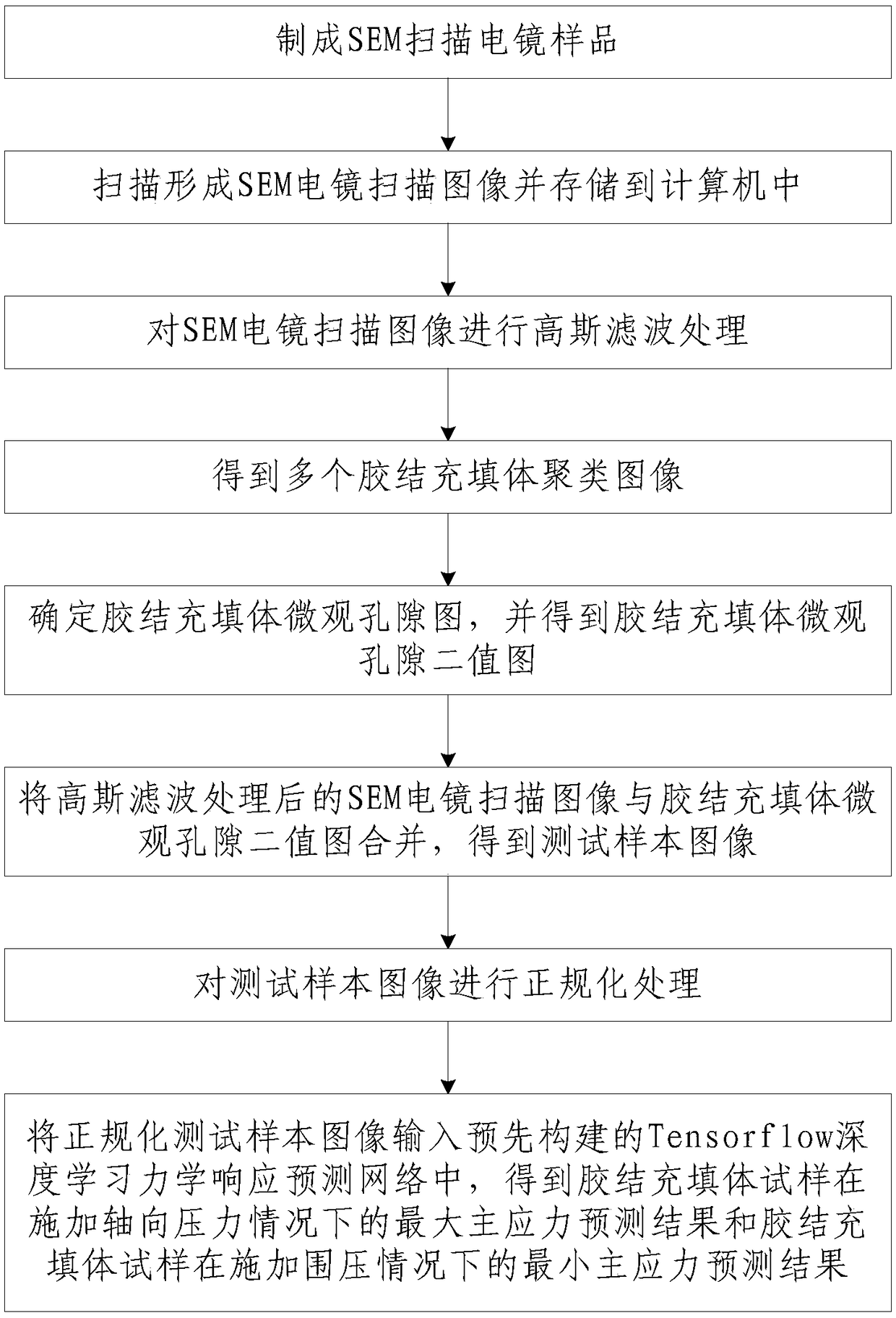

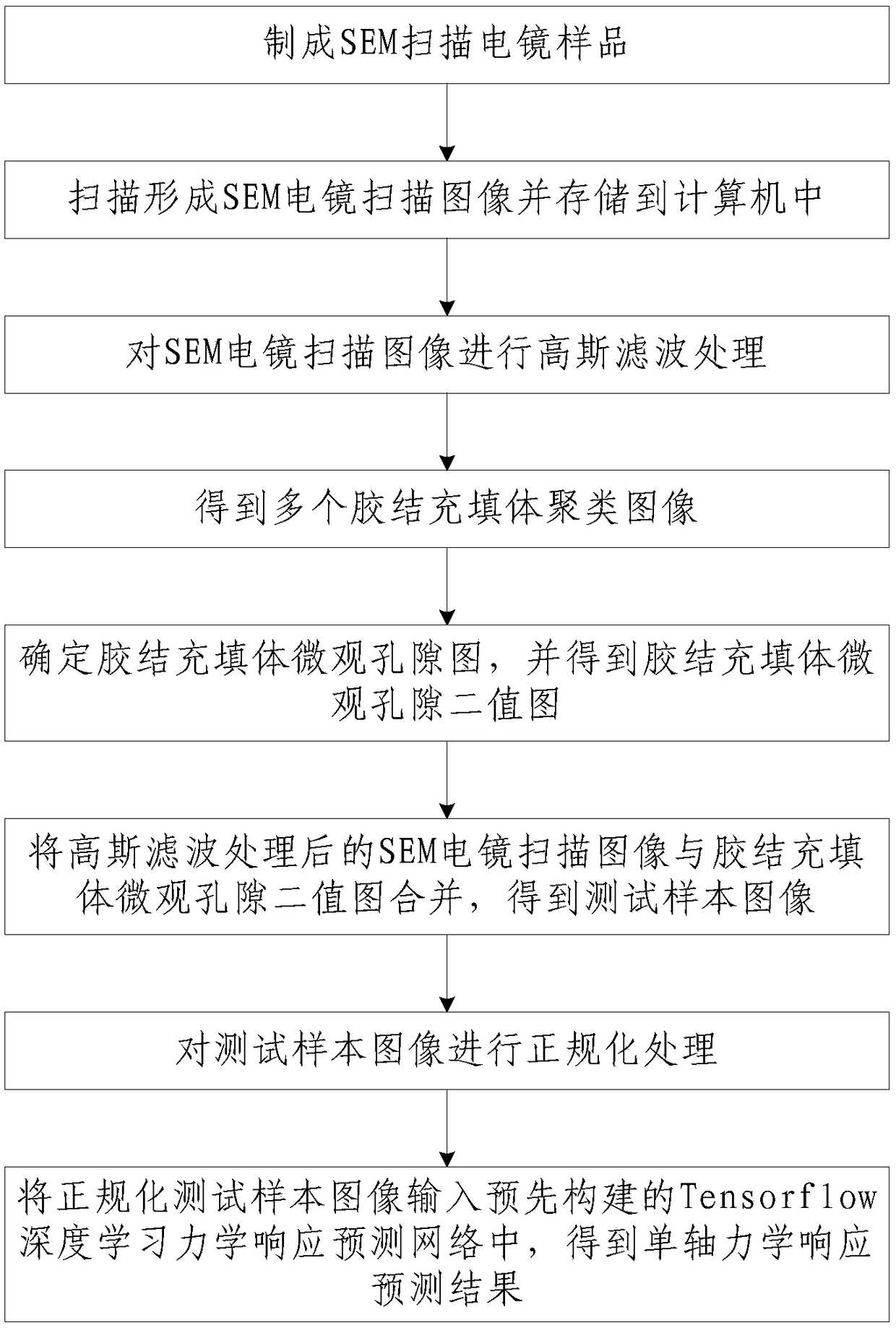

Cemented filling body mechanical response characteristic prediction method based on SEM (scanning electron microscopy) image

ActiveCN108256258AThe method steps are simpleNovel and reasonable designCharacter and pattern recognitionDesign optimisation/simulationPredictive methodsMaterial resources

The invention discloses a cemented filling body mechanical response characteristic prediction method based on an SEM (scanning electron microscopy) image. The method includes the steps: firstly, making an SEM sample; secondly, forming an SEM image in a scanning manner, and storing the image into a computer; thirdly, performing Gaussian filtering processing on the SEM image; fourthly, acquiring a plurality of clustering images of a cemented filling body; fifthly, determining a microscopic pore image of the cemented filling body to obtain a microscopic pore binary image of the cemented filling body; sixthly, combining the SEM image after Gaussian filtering processing and the microscopic pore binary image of the cemented filling body to obtain a testing sample image; seventhly, performing normalization processing on the testing sample image; eighthly, inputting the normalized testing sample image into a pre-built Tensorflow deep learning mechanical response prediction network to obtain auniaxial mechanical response prediction result. The method is high in prediction efficiency and has important significance for research of strength and stability of the cemented filling body, and consumed manpower and material resources are less.

Owner:XIAN UNIV OF SCI & TECH

Floor device capable of preventing electric shock in transformer substation

InactiveCN112081341ASimple stepsRelieve high temperatureTransformer housesEnclosed substationsElectric machineTransformer

The invention discloses a floor device capable of preventing electric shock in a transformer substation. The device comprises a box body, wherein a cavity is formed in the box body, a main belt wheelis rotatably connected to the inner wall of the front side of the cavity, a rotating ring which is symmetric about the center of the main belt wheel is arranged on the outer side of the main belt wheel, and a connecting cavity is formed between the rotating ring and the main belt wheel. The device is arranged on the ground of the transformer substation and used for preventing high-voltage electricity from touching the ground to injure maintenance personnel, has the functions of heat dissipation and water drainage, can effectively relieve high temperature in the transformer substation and accidents of water logging, and can lift an insulating plate when the high-voltage electricity touches the ground, and the insulating plate is still in a horizontal state after lifting, so that the maintenance personnel can tread the insulating plate conveniently, the insulating plate can move only when a motor is started, and safety is achieved.

Owner:曲周县旭如鑫贸易有限公司

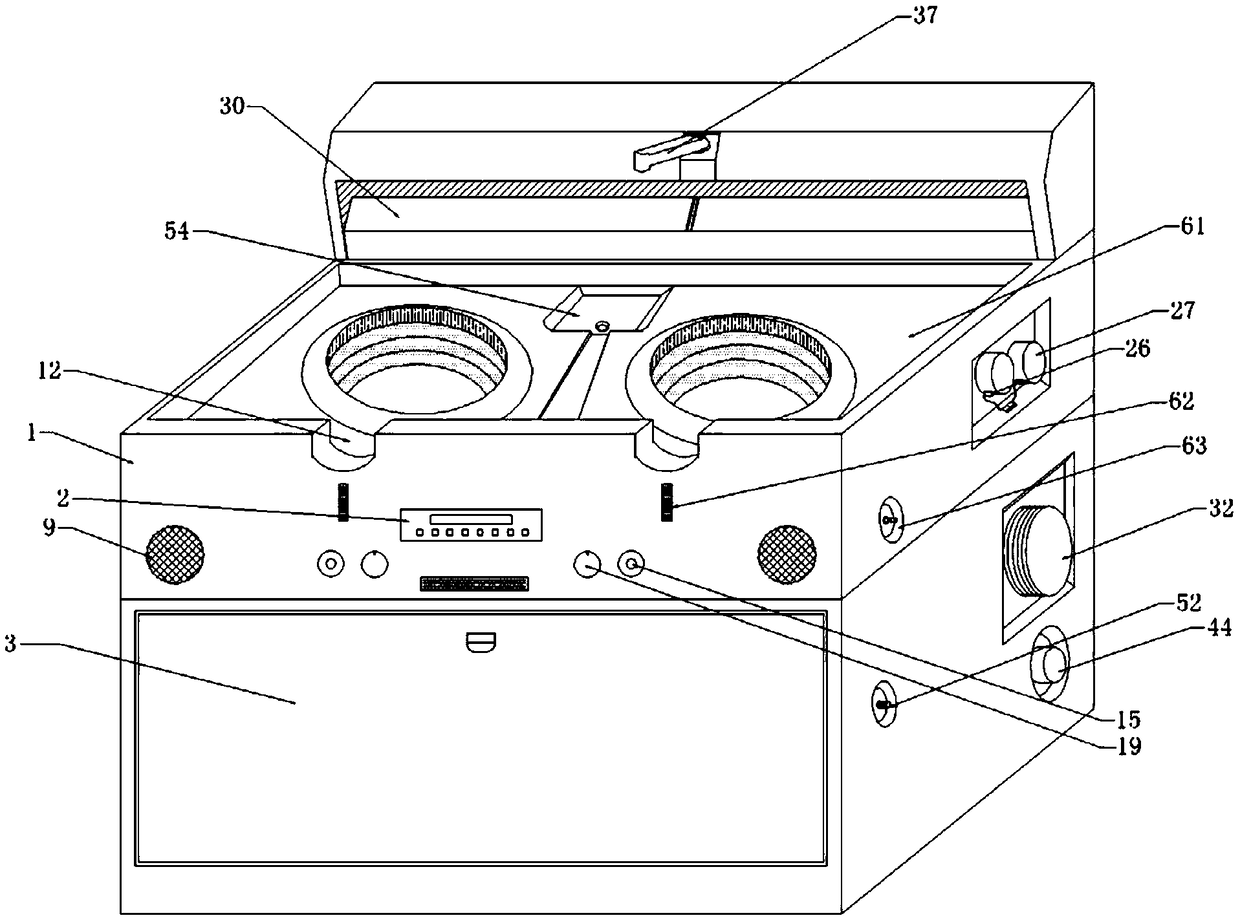

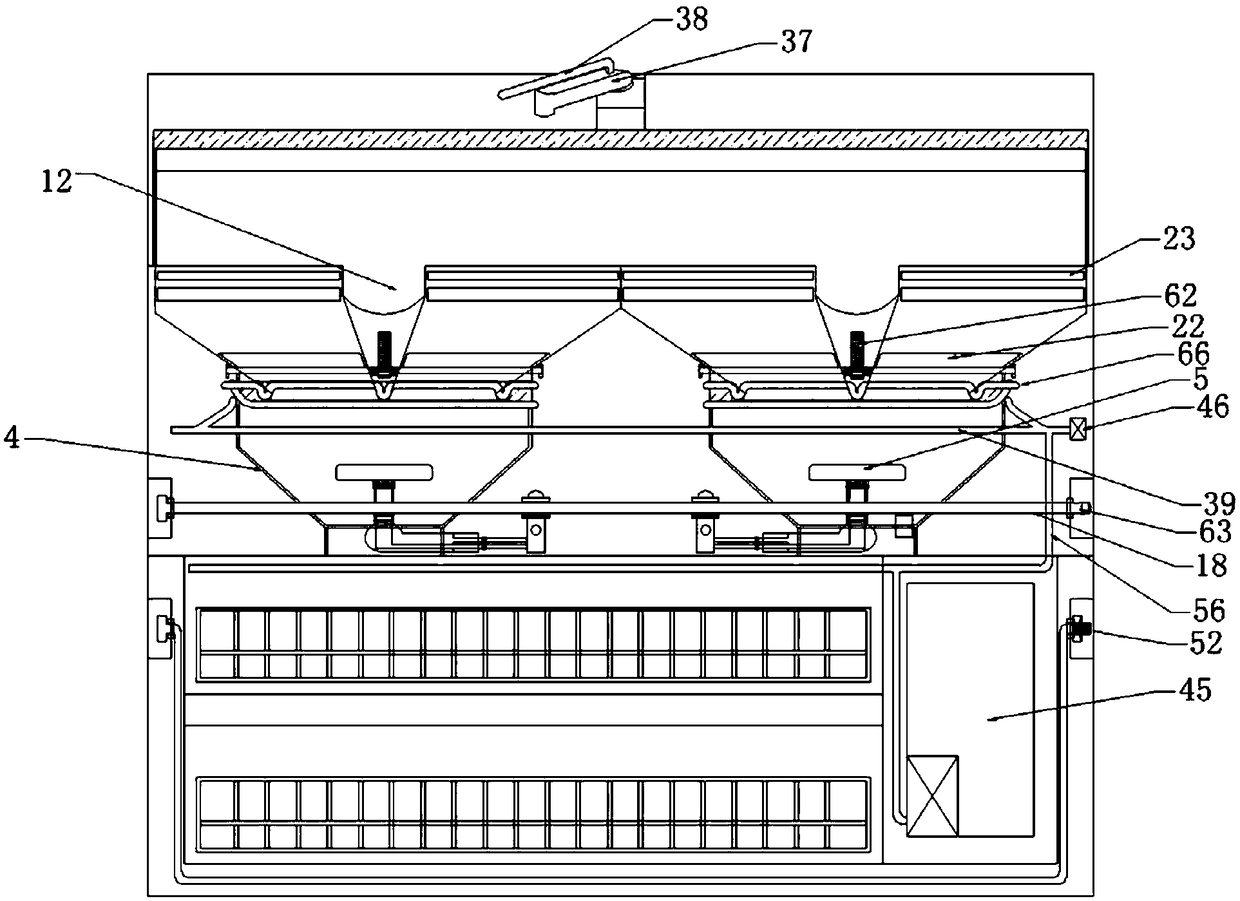

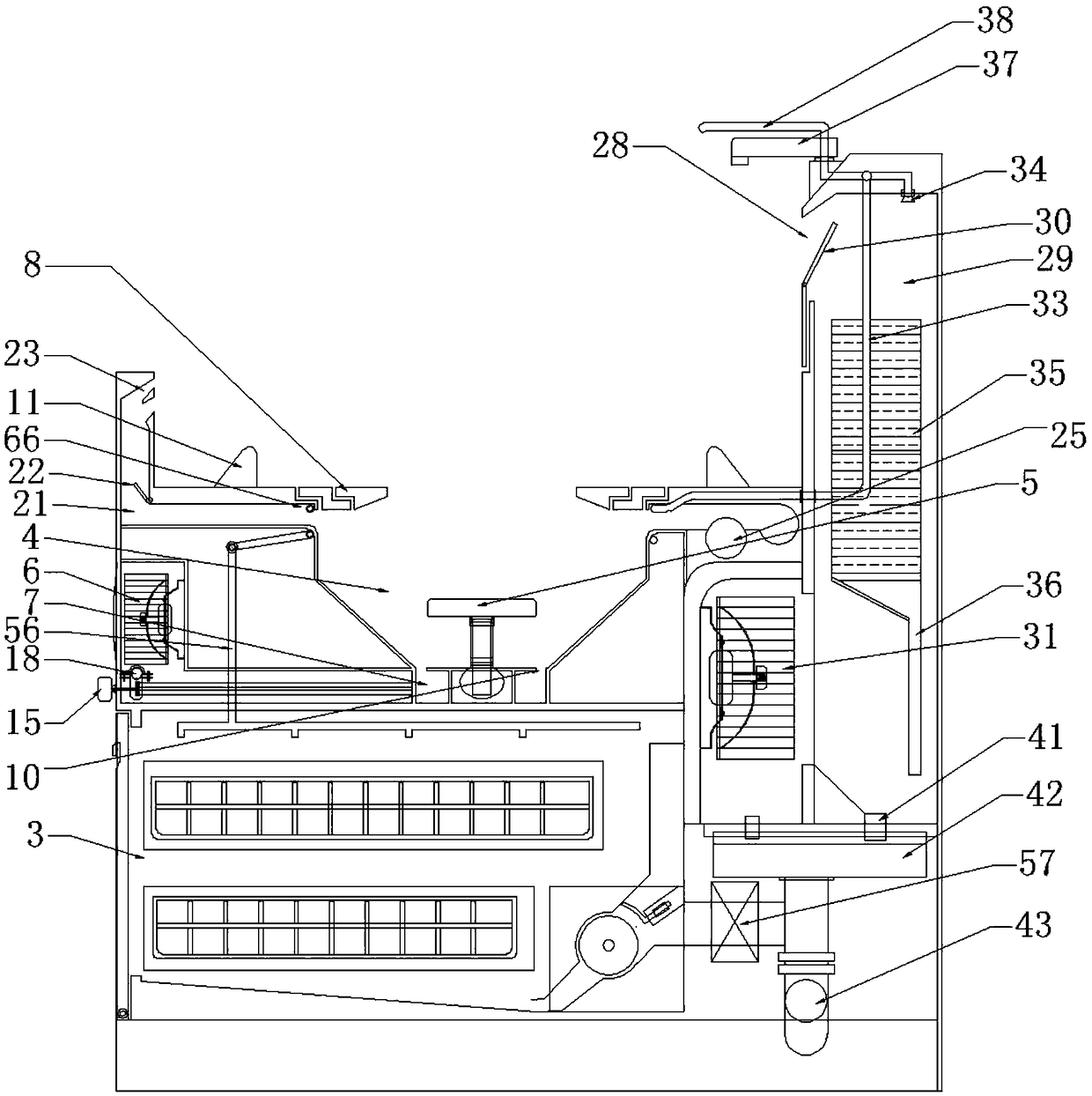

Intelligent and environmentally friendly integrated cooking stove integrating oil smoke separation and smoke guide energy concentration

PendingCN108895510APrevent wanton flyingReduce kinetic energyDomestic stoves or rangesTableware washing/rinsing machine detailsCombustion systemCombustion chamber

The invention discloses an intelligent and environmentally friendly integrated cooking stove integrating oil smoke separation and smoke guide energy concentration. The cooking stove comprises a closedcombustion stove body, a central control panel, an oil smoke separation system, a smoke guiding system, a combustion system, an exhaust gas discharge system, a water supply system, a sewage drain system and a dishwasher, the central control panel is located directly in front of the stove body, the dishwasher is arranged at the lower front portion of the stove body, the oil smoke separation systemis arranged at the upper rear portion of the stove body, inlets of the smoke guiding system and the exhaust gas discharge system are connected with the combustion chamber of the stove body, the watersupply system provides hot water for the oil smoke separation system and the dishwasher through the combustion system, and the sewage drain system is located at the lower portion of the oil smoke separation system. The stove adopts the method of water mists to strip and discharge oil stains in lampblack generated during cooking into sewage, the oil smoke free external discharge is achieved, a part of the waste hot gas generated during the combustion of the gas is used as the power for guiding the oil smoke, the closed combustion stove body not only gathers fire and saves energy, but also reduces the exhaust air volume and energy consumption of an exhaust fan, and the oil smoke is stopped from being affected by a rising hot air flow.

Owner:彭阔羽

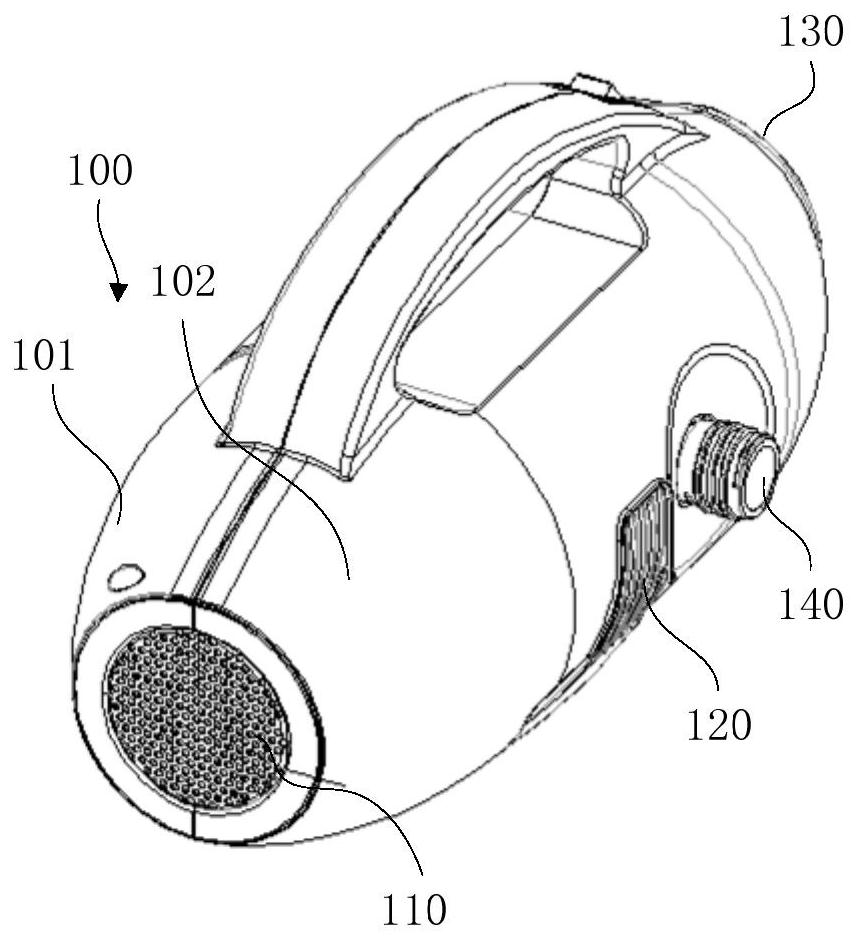

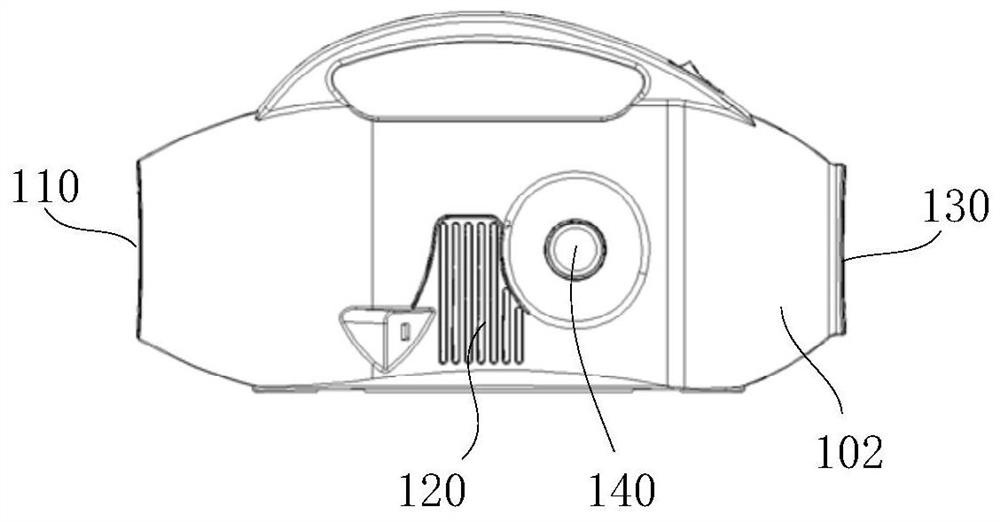

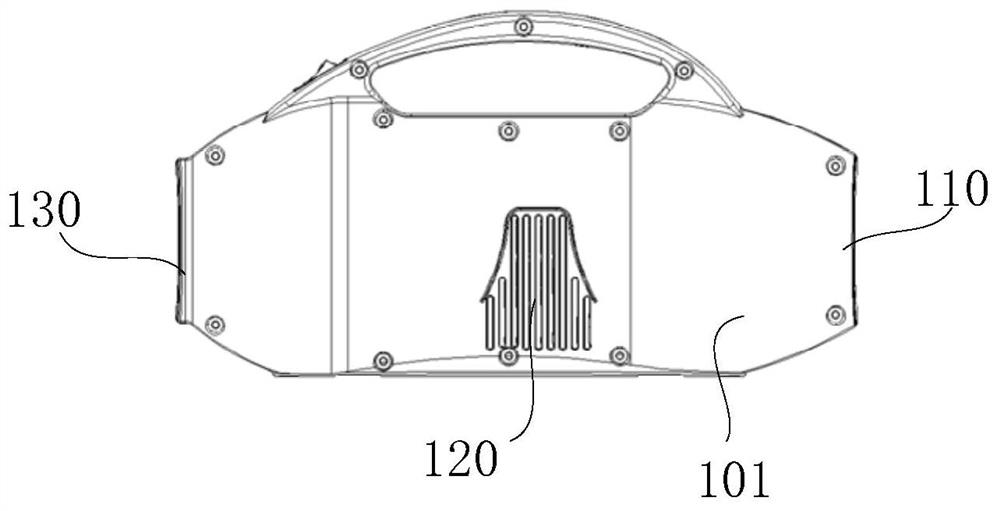

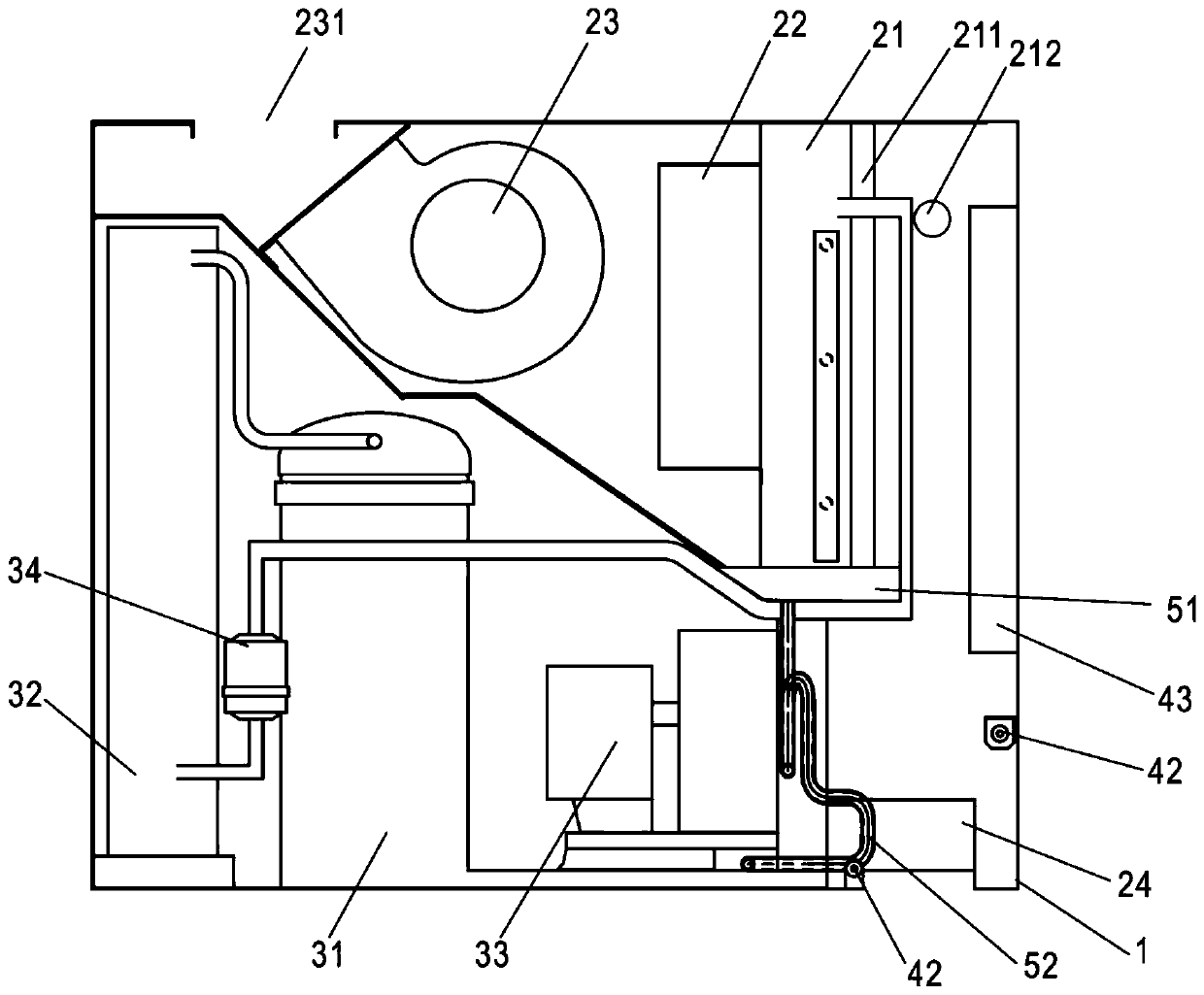

Electric air pump

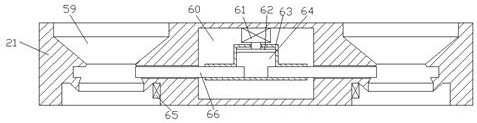

The invention relates to the technical field of air pumps, in particular to an electric air pump. The electric air pump is used for relieving the problems of high air outlet temperature and high shell temperature of an existing air pump, and comprises a pump shell, a heat dissipation motor and a blade motor, wherein the heat dissipation motor and the blade motor are arranged in the pump shell andsequentially arranged in the axial direction. The air pump is provided with an arc-shaped heat dissipation path, an inlet of the heat dissipation path is arranged at the first end in the axial direction of the air pump, and an outlet of the heat dissipation path is arranged on the outer peripheral wall of the air pump; the air pump is provided with an arc-shaped inflation path, an inlet of the inflation path is arranged at the second end in the axial direction of the air pump, and an outlet of the inflation path is arranged on the outer peripheral wall of the air pump; and the first end and the second end are respectively two ends in the axial direction of the air pump. The problems of high air outlet temperature and high shell temperature of the existing air pump are effectively relieved.

Owner:JIANGSU YOUMAY ELECTRIC APPLIANCE

Double-air-inlet type drainage anti-reverse-suction air conditioner

PendingCN110843833AReduce high temperatureRelieve high temperatureRailway heating/coolingWater storageFresh air

Provided is a double-air-inlet type drainage anti-reverse-suction air conditioner. An evaporator of the double-air-inlet type drainage anti-reverse-suction air conditioner is arranged at the upper endof the rear portion of the inner side of a box body. An electric heater is arranged at the front end of the evaporator. A ventilator is arranged at the upper end of the front portion of the inner side of the box body. A fresh air fan is arranged at the bottom end of the rear portion of the inner side of the box body. An air inlet of a compressor is connected with an air outlet of the evaporator through a pipeline. An air outlet of the compressor is connected with an air inlet of a condenser arranged at the front portion of the inner side of the box body through a pipeline. The air inlet of the condenser is connected with the evaporator through a pipeline through a drying filter. A high-pressure switch is arranged on a pipeline between the compressor and the condenser. A low-pressure switch is arranged on a pipeline between the compressor and the evaporator. A water storage disc is arranged at the bottom of the evaporator. A double-U-shaped drainage pipe is connected to the bottom of the water storage disc. According to the double-air-inlet type drainage anti-reverse-suction air conditioner, indoor and outdoor air inlet can be achieved, and meanwhile, the water drainage anti-reverse-suction cooling effect is good; and the local high temperature of the interior of a cab, a mechanical room and an electric appliance room in a locomotive can be rapidly reduced.

Owner:ZHUZHOU RAILWAY HUANJI ELECTRONICS APPLIANCES FACTORY

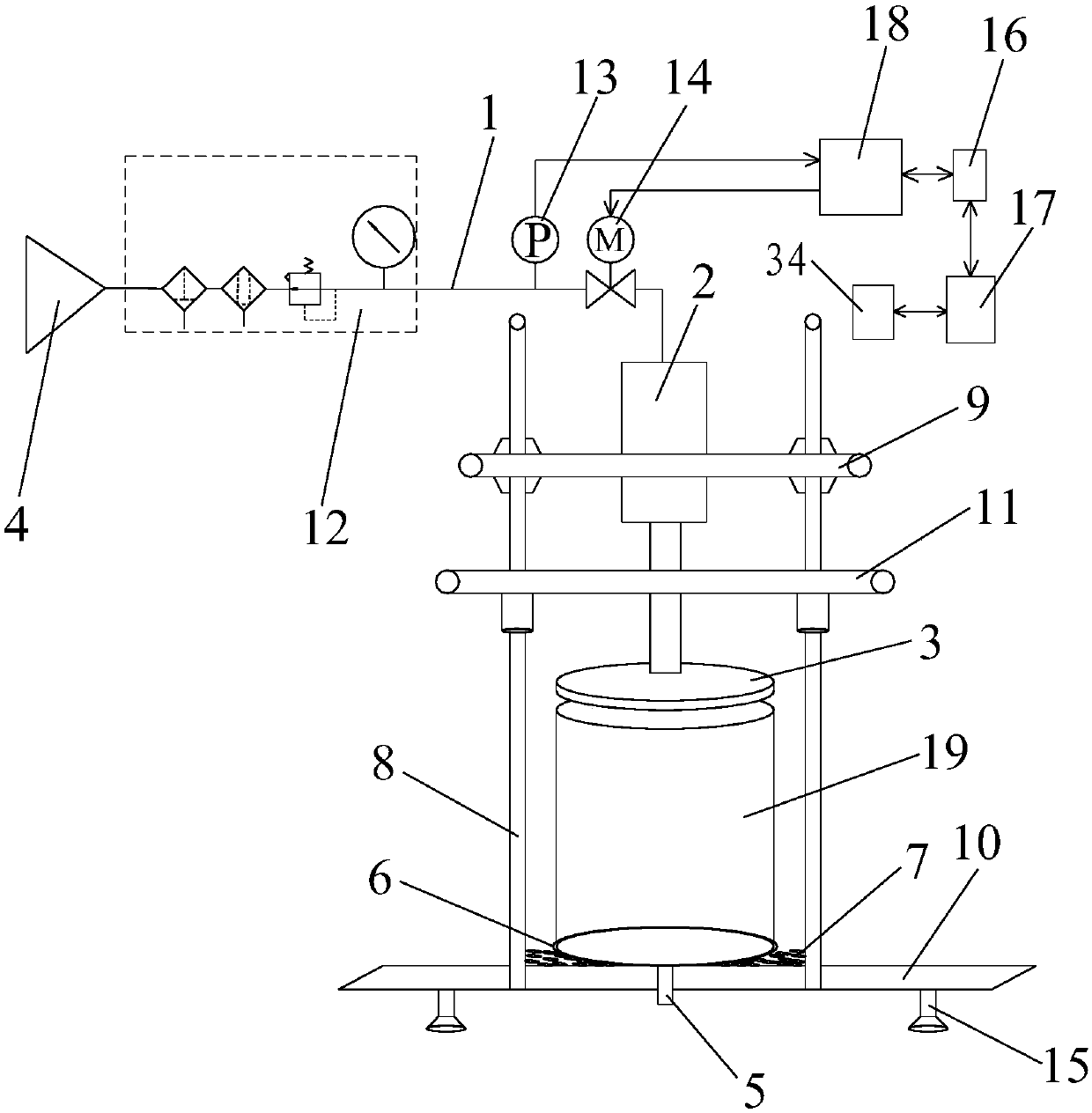

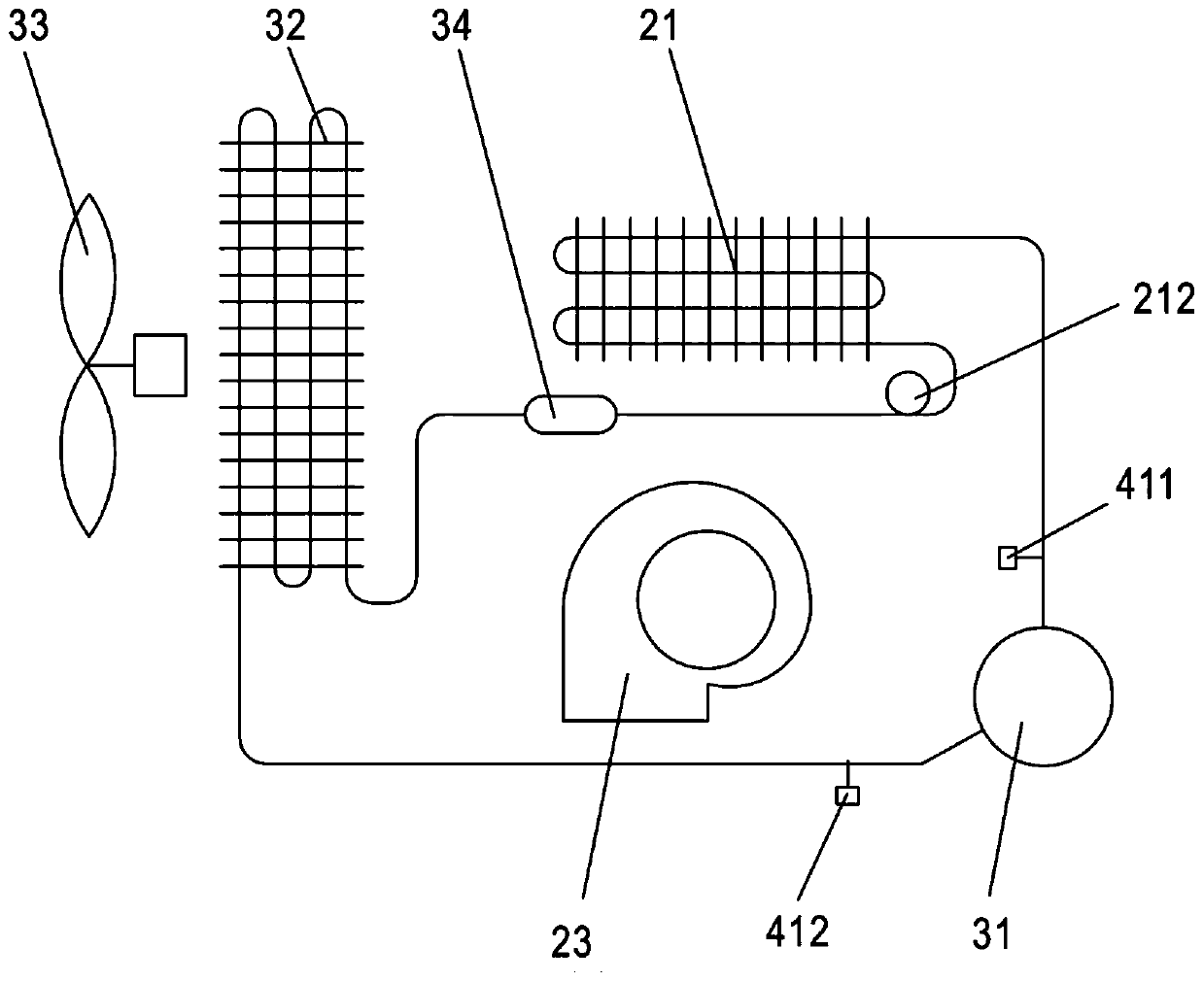

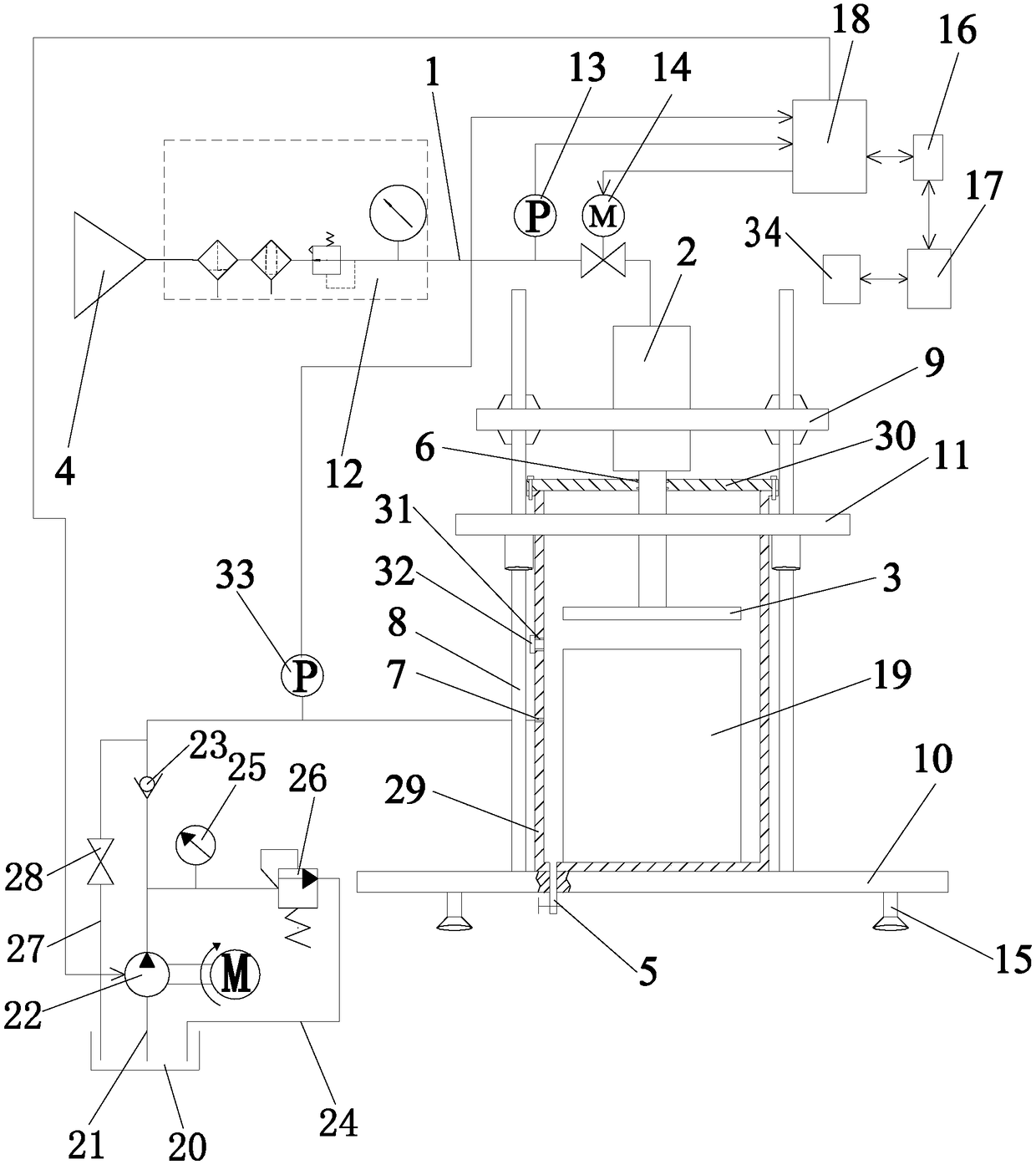

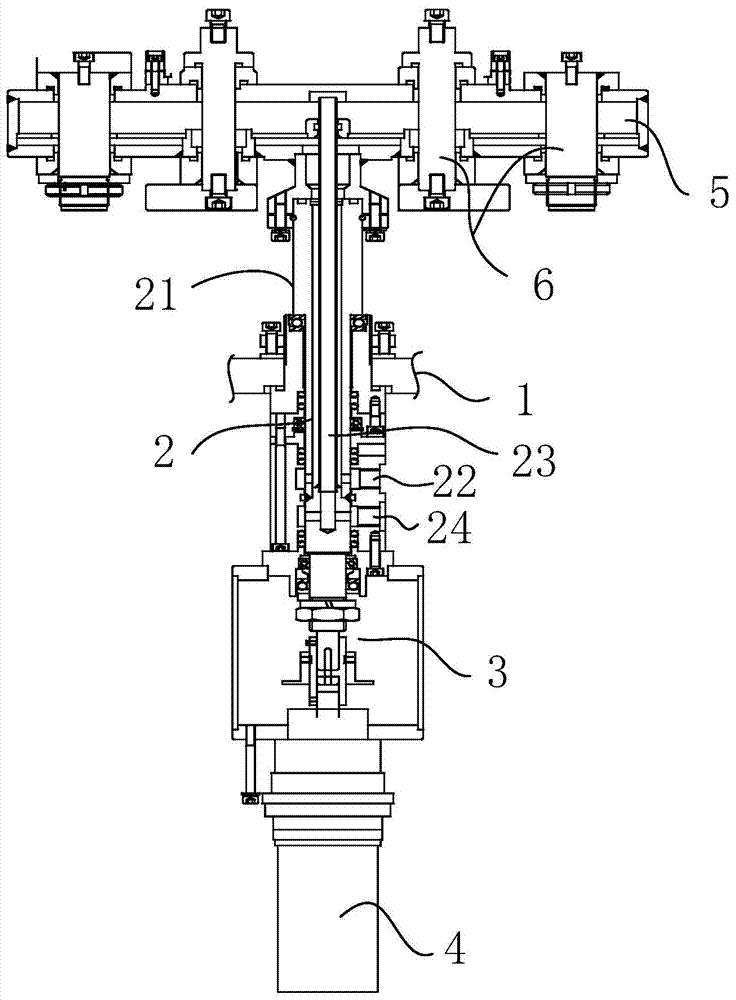

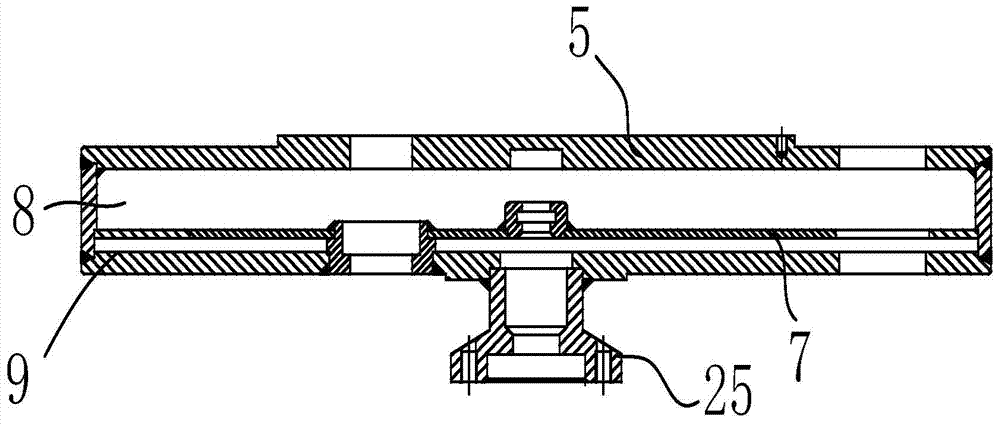

A test system and method for mechanical response characteristics of cemented filling body

ActiveCN108240940BThe method steps are simpleNovel and reasonable designMaterial strength using tensile/compressive forcesMaterial analysis by measuring secondary emissionTest sampleScanning electron microscope

The invention discloses a mechanical response characteristic testing system and method for a cemented filling body. The system comprises a cemented filling body three-axis compressive strength testingdevice, a computer and an SEM scanning electron microscope. The method comprises the following steps: I, preparing an SEM sample; II, forming an SEM scanning image; III, carrying out Gaussian filterprocessing on the SEM scanning image; IV, obtaining a plurality of cemented filling body clustering images; V, determining a cemented filling body microcosmic porous image to obtain a cemented fillingbody microcosmic binary image; VI, obtaining a test sample image; VII, normalizing the test sample image; and VIII, inputting the normalized test sample in a pre-established Tensorflow deep learningmechanical response prediction network to obtain a three-axis mechanical response prediction result. According to the method, steps are simple, the prediction efficiency is high and functions are comprehensive, and the method has important meaning on researching strength and stability of the cemented filling body.

Owner:陕西嘉墨能源科技有限公司

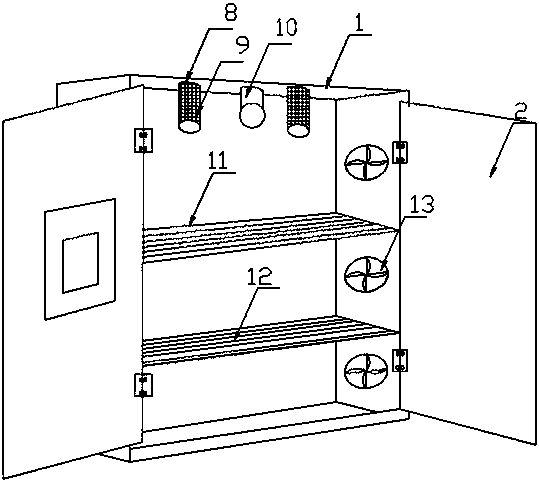

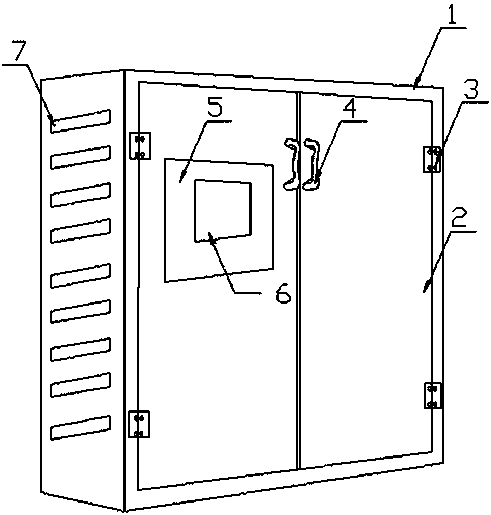

An integrated holding cabinet for multiple vacuum circuit breakers

InactiveCN107658709AEasy to installExtended service lifeSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDrying AgentsEngineering

The invention provides an integrated holding cabinet for multiple vacuum circuit breakers. The integrated holding cabinet comprises a holding cabinet body and two cabinet doors which are fixedly connected to the holding cabinet body via hinges; the cabinet doors are provided with handles; a piece of transparent glass is inlaid in one cabinet door and an LED data recorder is arranged in the middleof the transparent glass; one side of the holding cabinet body is provided with a plurality of ventilation holes and the other side of the holding cabinet body is provided with a plurality of fans; the top side of the inside of the holding cabinet body is provided with an LED lighting tube and a plurality of drying boxes holding drying agents; the inside of the holding cabinet body is divided intothree chambers with the same size via a first baffle plate and a second baffle plate. The integrated holding cabinet for multiple vacuum circuit breakers has the advantages that the ventilation holesand the fans can relieve high temperature in the cabinet body; the drying agents in the drying boxes can absorb moisture to prolong the service life; the LED lighting tube enables people to perform maintenance work in an environment with poor lighting conditions conveniently.

Owner:江苏宏达电气有限公司

Three-clutch automatic speed changer

InactiveCN108691961ARelieve high temperatureReduce wear and tearToothed gearingsAutomatic transmissionVariator

A three-clutch automatic speed changer comprises a clutch, a transmission output shaft, transmission gears, a linkage device and a linkage body. The three-clutch automatic speed changer is characterized in that the clutch is composed of three clutch bodies including the first clutch body, the second clutch body and the third clutch body; according to the distribution character of the various gearsof transmission gears on three clutch shafts, except the lowest gear, the highest gear and the reverse gear, each work gear of each clutch shaft is provided with two preparing gears arranged on the other two clutch shafts correspondingly, wherein one preparing gear is higher than the work gear by one level, and the other preparing gear is lower than the work gear by one level. The three-clutch automatic speed changer has the beneficial effects that the phenomenon of gear shifting delaying like double-clutch speed changers cannot happen; and when the road jams, the high temperature and abrasion of the clutch can be relieved.

Owner:陈学琴

Prediction method of mechanical response characteristics of cemented filling body based on SEM image

ActiveCN108256258BThe method steps are simpleNovel and reasonable designCharacter and pattern recognitionDesign optimisation/simulationSample imageMaterial resources

The invention discloses a method for predicting the mechanical response characteristics of a cemented filling body based on an SEM image, which comprises the steps of: 1. making a SEM scanning electron microscope sample; 2. scanning to form a SEM scanning electron microscope scanning image and storing it in a computer; The scanned image is processed by Gaussian filtering; 4. Obtain multiple cluster images of cemented filling bodies; 5. Determine the microscopic pore map of the cemented filling body, and obtain the binary image of the microscopic pores of the cemented filling body; 6. Scan the SEM electron microscope after Gaussian filtering The image is merged with the microscopic pore binary image of the cemented filling body to obtain the test sample image; 7. Normalize the test sample image; 8. Input the normalized test sample image into the pre-built Tensorflow deep learning mechanical response prediction network to obtain Uniaxial mechanical response prediction results. The invention has high prediction efficiency, consumes less manpower and material resources, and has great significance for studying the strength and stability of cemented filling bodies.

Owner:XIAN UNIV OF SCI & TECH

Method for Predicting Mechanical Response Characteristics of Consolidated Filling Body Based on Sensitive Microscopic Parameters

ActiveCN108229062BNovel and reasonable designImprove efficiencyBiological neural network modelsCharacter and pattern recognitionMaterial resourcesStatistical physics

Owner:XIAN UNIV OF SCI & TECH

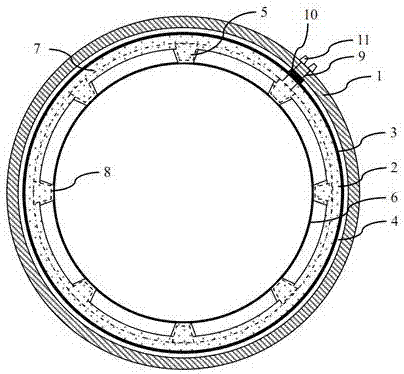

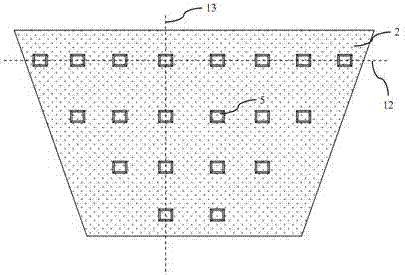

A metal smelting holding furnace

ActiveCN107401919BAvoid direct deliveryRelieve high temperatureFurnace componentsCrucible furnacesElectricityBrick

The invention provides a metal-smelting heat-preserving furnace. The metal-smelting heat-preserving furnace is provided with a cylindrical furnace body structure, wherein the furnace body comprises a housing at the outermost side, a refractory brick layer positioned in the housing and a crucible at the innermost side, wherein a vacuum insulating cavity is arranged between the housing and the refractory brick layer; a plurality of bumps are arranged on the inner surface of the refractory brick layer; the bumps are in tight contact with the crucible; a first heating element is arranged in the refractory brick layer, and the first heating element is a spiral electric heating wire; each of the bumps is provided with an independent electric heating element; the second electric heating elements are mutually independent from a control circuit of the first electric heating element; the second heating elements guide out electrode terminals through heat-resistant conductive rods; the heat-resistant conductive rods pass through one part of the refractory brick layer, the vacuum isolating cavity and the housing, and the electrode terminals are externally connected with control circuits for controlling working states of the second heating elements; the bumps are distributed in the form of an array, and part of the second electric heating elements can be electrically heated selectively.

Owner:南通高新工业炉有限公司

Prediction method of mechanical response characteristics of cemented filling body based on image and microscopic parameters

ActiveCN108445030BPredicting Mechanical Response PropertiesThe method steps are simpleImage enhancementImage analysisPredictive methodsScanning electron microscope

The invention discloses a method for predicting the mechanical response characteristics of a cemented filling body based on images and microscopic parameters, comprising the steps of: 1. making a SEM scanning electron microscope sample; 2. scanning to form a SEM scanning electron microscope image and storing it in a computer; 3. Gaussian filter processing on the scanning image of the SEM electron microscope; 4. Obtain multiple cluster images of cemented filling bodies; 5. Determine the microscopic pore map of the cemented filling body, and obtain the binary map of the microscopic pores of the cemented filling body; 6. Analyze the microscopic pores of the cemented filling body 2 The value map is analyzed and processed to obtain multiple microscopic parameters of the cemented filling body; 7. Input the multiple microscopic parameters of the cemented filling body into the pre-built Tensorflow deep learning mechanical response prediction network to obtain the uniaxial mechanical response prediction result. The invention has high prediction efficiency, high prediction accuracy, less manpower and material resources consumption, is of great significance for studying the strength and stability of cemented filling bodies, has strong practicability, and has high popularization and application value.

Owner:XIAN UNIV OF SCI & TECH

A kind of sponge city permeable brick

The invention discloses a sponge city permeable brick, which comprises a hollow brick body. The upper end of the brick body is provided with a water inlet. The inner wall of the brick body is provided with two symmetrically arranged lifting grooves. The bottom of the tank is mutually offset by a partition, and the two ends of the partition are respectively sealed and slidably connected with the inner walls of the two lifting grooves. The upper end of the partition is fixed with a plurality of columns, and the upper end of each column is provided with a A chute, the inner bottom of each chute is fixed with an air bag. The advantage is that the barrier of the partition makes the rainwater enter the brick body through the water inlet and does not directly infiltrate into the underground water channel, but is first stored inside the brick body, so that the rainwater can be stored to a certain extent, which is convenient for water replenishment after the rain stops Into the air to improve the comfort of the urban environment; when there is a lot of water, the water flow will enter the outlet tank, and then be discharged into the underground water channel through the downpipe to ensure the normal progress of urban drainage.

Owner:湖南凯迪工程科技有限公司

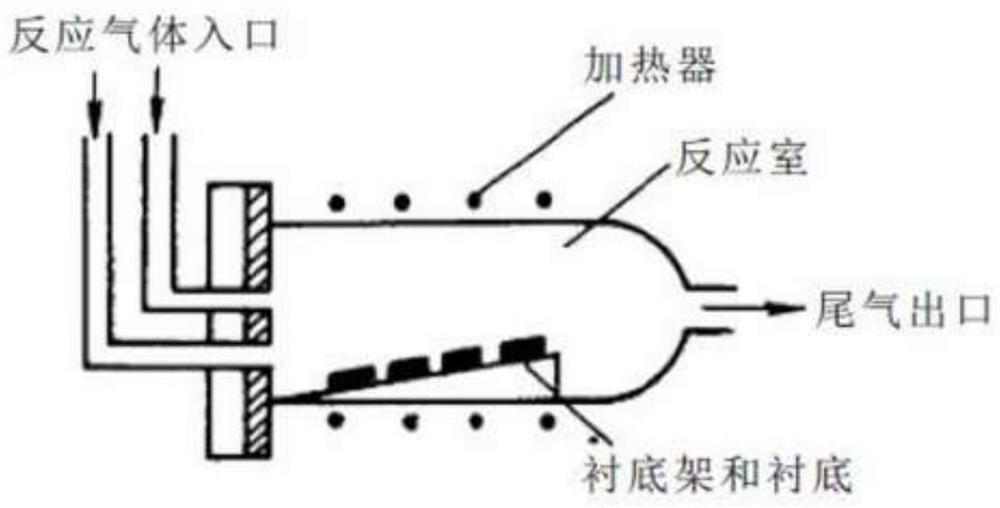

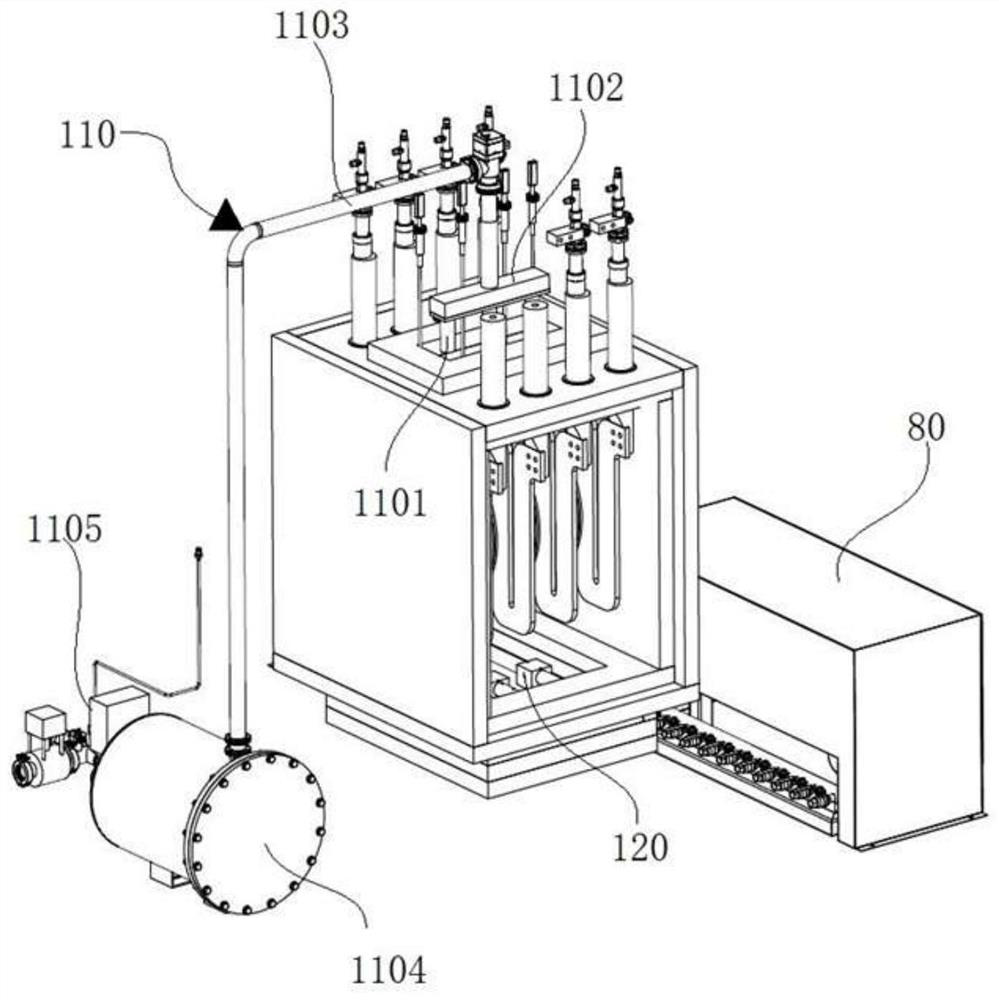

Uniform heating device for vapor deposition and vapor deposition furnace

ActiveCN109423631BAvoid uneven heatingExquisite designChemical vapor deposition coatingGraphite electrodeHeat transmission

The invention discloses a vapor deposition uniform heating device and a vapor deposition furnace. The vapor deposition uniform heating device comprises at least two heating plates arranged at intervals, the heating plates coincide with projections on a same projection surface parallel to the two heating plates, heating space used for placing workpieces is formed in gaps between the adjacent heating plates, graphite electrodes are separately connected to the two ends of each heating plate, and each graphite electrode is connected with a copper electrode used for connecting power supply. The design is ingenious, the heating space used for placing workpieces is formed in the gaps between the two adjacent heating plates, the two heating plates directly heat the workpieces from two opposite directions simultaneously, on the one hand, the higher heating efficiency is achieved, thermal loss in the thermal transmission process is reduced, and the reduction of energy consumption is facilitated;and meanwhile, two surfaces are heated simultaneously, the guarantee of heating homogeneity is facilitated, and nonuniform heating of the workpieces is avoided.

Owner:SUZHOU SICREAT NANOTECH CO LTD

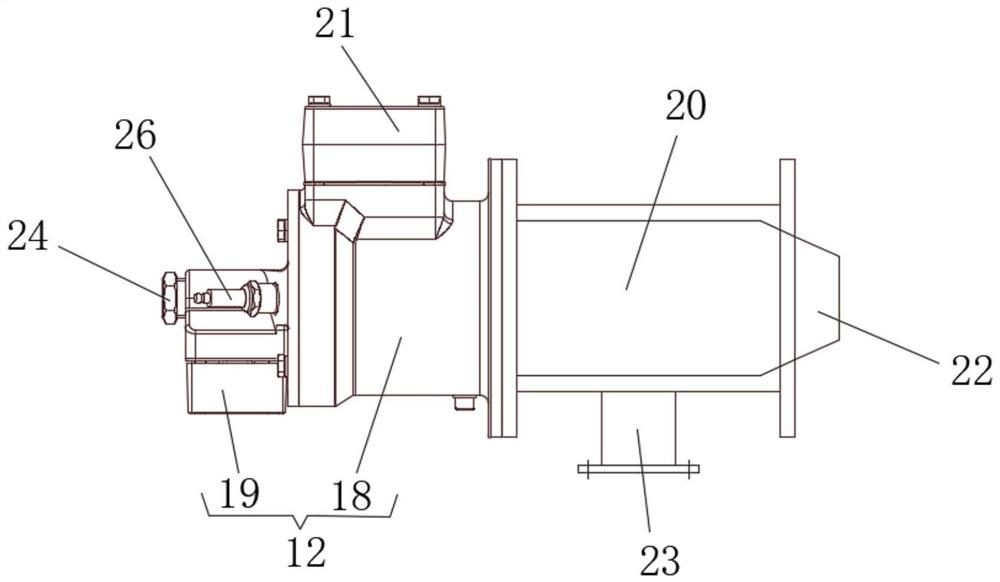

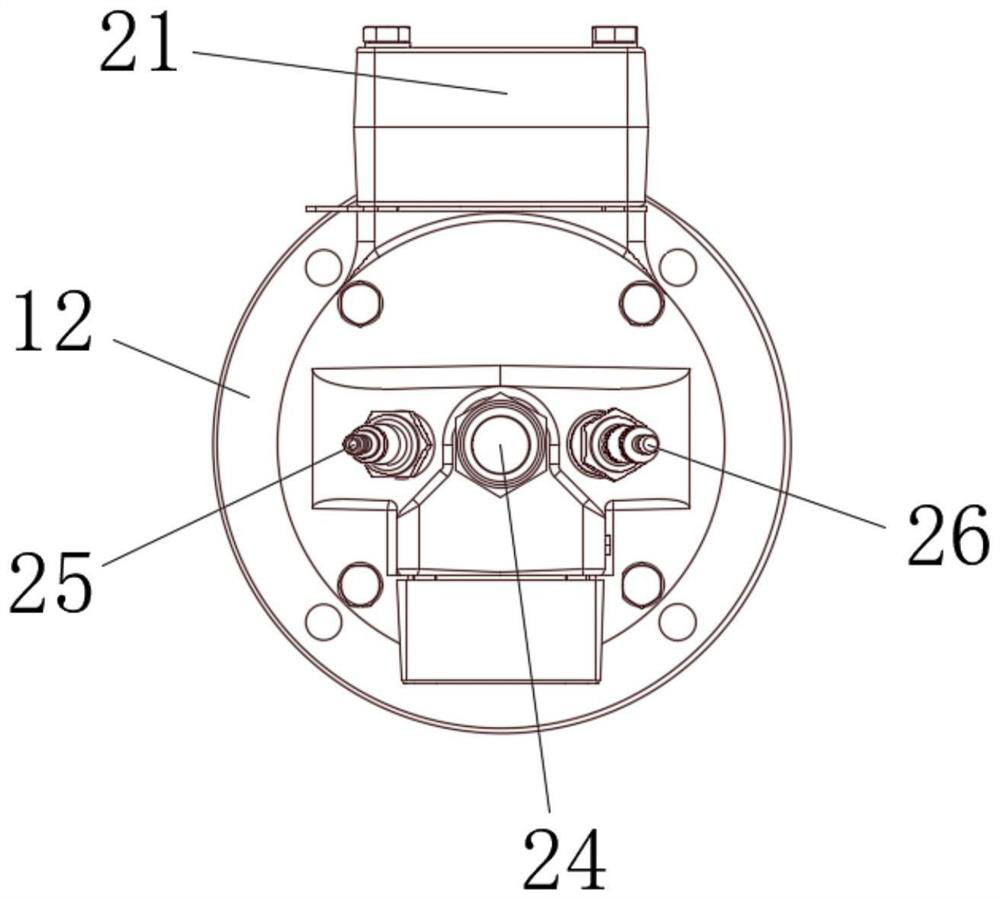

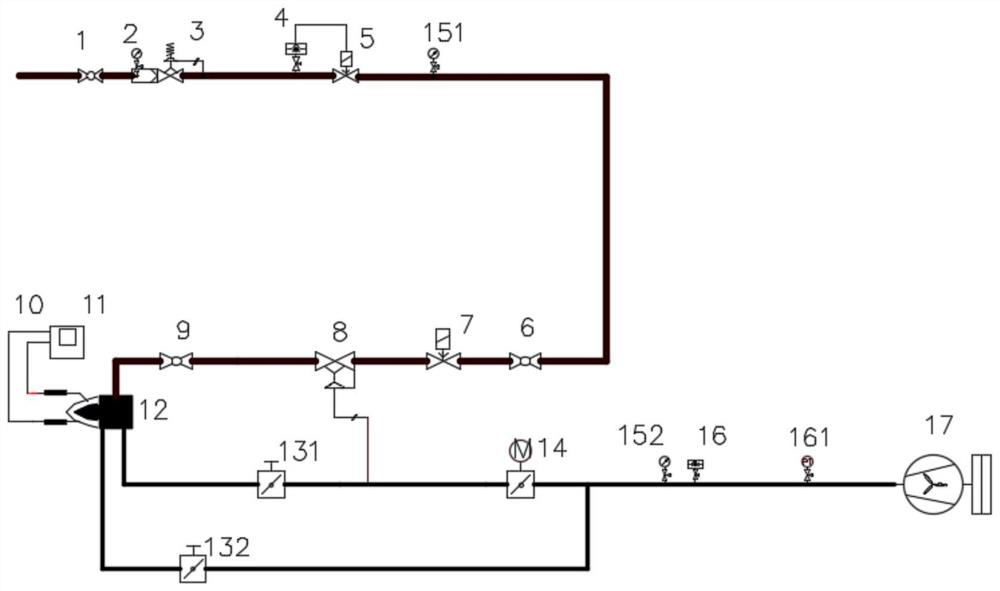

Combustion device for waste precipitation in sewage treatment

InactiveCN114484466AGuaranteed air volume for combustionGuaranteed treatment effectIncinerator apparatusCombustorAir volume

The invention discloses a combustion device for waste precipitation in sewage treatment, which comprises a positive pressure combustor and a fan, the positive pressure combustor is formed by combining a combustor body and a control part, the combustor body is of a cavity structure, the control part is arranged at the front end of the combustor body, an air distribution part is arranged at the rear end of the combustor body, and the fan is arranged at the front end of the combustor body. A gas distribution part is arranged at the upper end of the burner body, a first connector and a second connector are arranged on the control part, the upper end of the gas distribution part is connected with gas supply equipment through a gas pipe, and the gas flows from the gas supply equipment to the burner on the gas pipe; the positive displacement fan is adopted at the air distribution part to replace a conventional centrifugal fan, and the positive displacement fan has the characteristic of equal air supply, so that the pressure change of the air outlet and the air supply amount are basically kept unchanged, the air quantity for combustion is ensured, and the problem of incomplete combustion is avoided.

Owner:江苏德瑞环保科技有限公司

A kind of ceramic material crushing equipment and ceramic material processing technology

ActiveCN113246296BReduce external temperatureRelieve high temperatureClay processing apparatusElectric machineMaterials processing

The invention discloses a ceramic material pulverizing equipment and a ceramic material processing technology, comprising: a box body, a rotary motor is fixedly connected to the top of the box body, an output shaft of the rotary motor penetrates through the interior of the box body, and the The bottom of the output shaft of the rotating electrical machine is fixedly connected with a connecting seat, the bottom of the connecting seat is threadedly connected with a mounting column, the outer side of the mounting column is uniformly distributed in a ring shape from top to bottom, and the lower end of the mounting column is provided with crushing knives. An installation groove is opened inside, and a micro data processor is fixedly connected to the inside of the installation groove, and a stirring plate uniformly and fixedly connected to the outer wall of the installation column is arranged below the pulverizing knife. After long-term continuous operation, the outer surface of the pulverizing knife is cooled to prolong the service life of the pulverizing knife, and the pulverizing knife can be replaced independently, reducing the cost of maintenance and replacement, and can effectively improve the uniformity of material particles in the pulverizing process.

Owner:衡阳阳光古建建材有限责任公司

Metal-smelting heat-preserving furnace

ActiveCN107401919AAvoid direct deliveryRelieve high temperatureFurnace componentsCrucible furnacesElectricityBrick

The invention provides a metal-smelting heat-preserving furnace. The metal-smelting heat-preserving furnace is provided with a cylindrical furnace body structure, wherein the furnace body comprises a housing at the outermost side, a refractory brick layer positioned in the housing and a crucible at the innermost side, wherein a vacuum insulating cavity is arranged between the housing and the refractory brick layer; a plurality of bumps are arranged on the inner surface of the refractory brick layer; the bumps are in tight contact with the crucible; a first heating element is arranged in the refractory brick layer, and the first heating element is a spiral electric heating wire; each of the bumps is provided with an independent electric heating element; the second electric heating elements are mutually independent from a control circuit of the first electric heating element; the second heating elements guide out electrode terminals through heat-resistant conductive rods; the heat-resistant conductive rods pass through one part of the refractory brick layer, the vacuum isolating cavity and the housing, and the electrode terminals are externally connected with control circuits for controlling working states of the second heating elements; the bumps are distributed in the form of an array, and part of the second electric heating elements can be electrically heated selectively.

Owner:南通高新工业炉有限公司

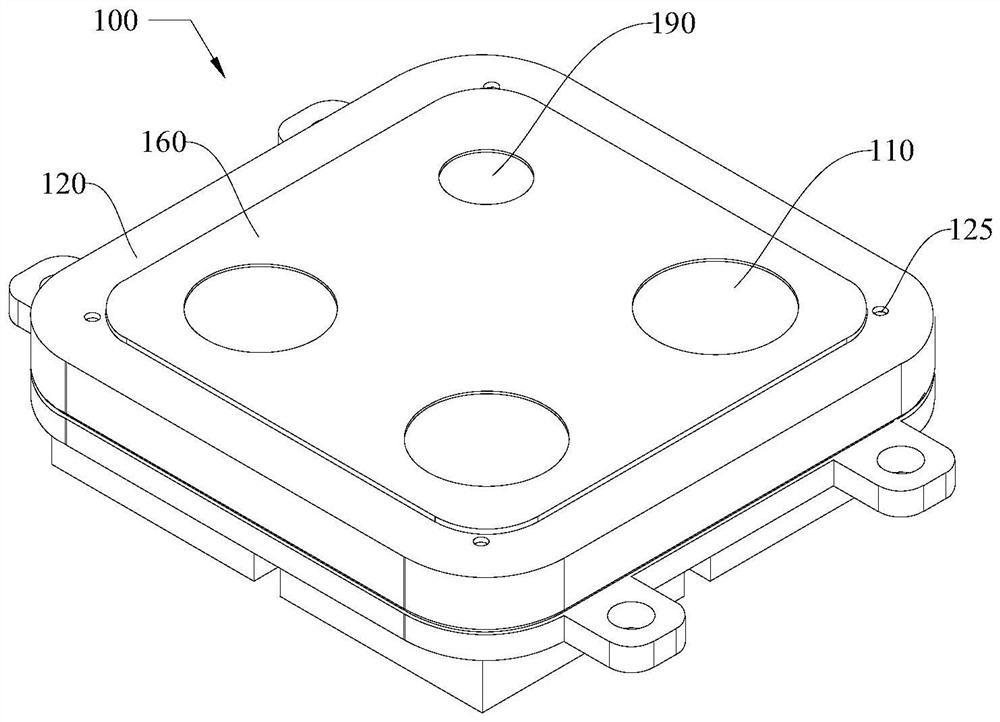

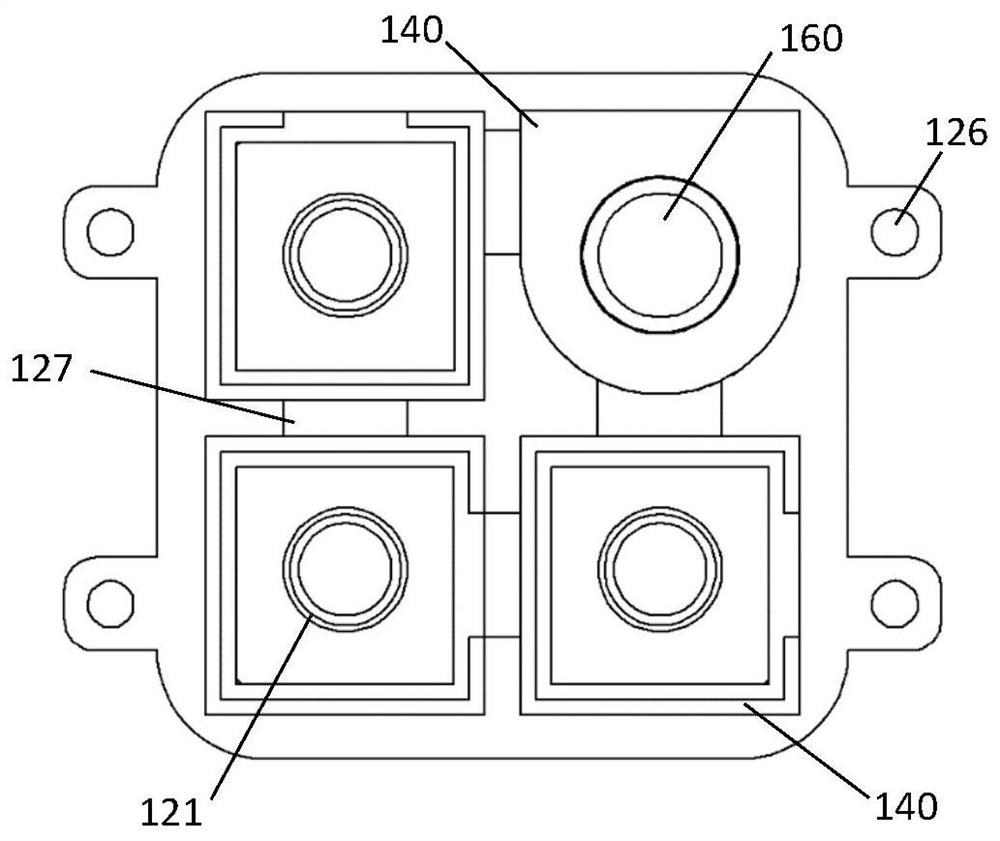

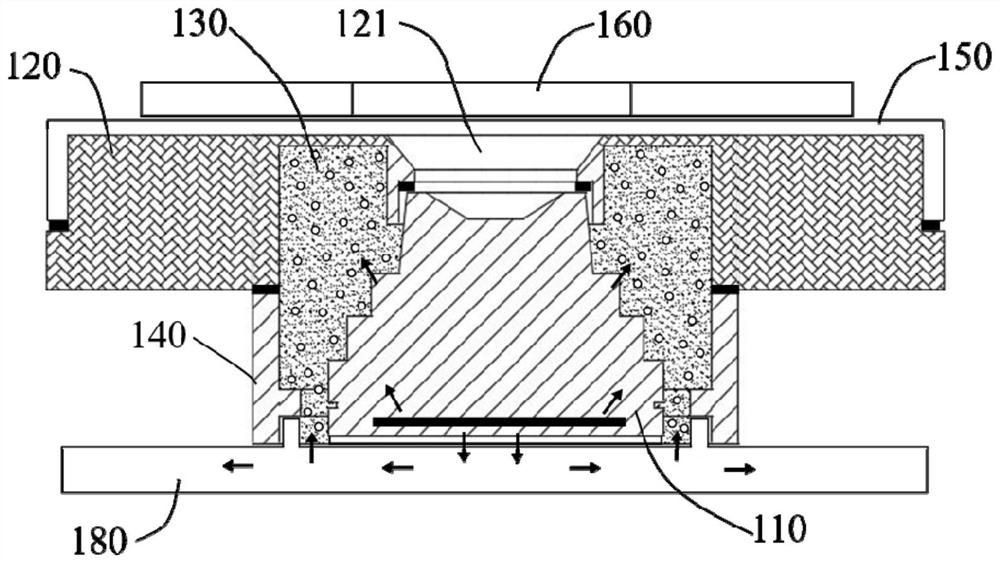

Camera module and electronic equipment

PendingCN113286068AImprove cooling effectRelieve high temperatureTelevision system detailsColor television detailsEngineeringCamera module

The embodiment of the invention provides a camera module and electronic equipment, and relates to the field of electronic equipment. The camera module comprises a camera, a module body and a phase change filling body; a fixing groove is formed in the module body, the fixing groove penetrates through the module body, the camera is installed in the fixing groove and exposed out of the fixing groove, and the gap between the camera and the module body is filled with the phase change filling body. According to the embodiment of the invention, good heat dissipation of the camera can be realized, so that the working stability of the camera is ensured.

Owner:WINGTECH COMM

Mechanical response characteristic testing system and method for cemented filling body

ActiveCN108240940AThe method steps are simpleNovel and reasonable designMaterial strength using tensile/compressive forcesMaterial analysis by measuring secondary emissionTest sampleScanning electron microscope

The invention discloses a mechanical response characteristic testing system and method for a cemented filling body. The system comprises a cemented filling body three-axis compressive strength testingdevice, a computer and an SEM scanning electron microscope. The method comprises the following steps: I, preparing an SEM sample; II, forming an SEM scanning image; III, carrying out Gaussian filterprocessing on the SEM scanning image; IV, obtaining a plurality of cemented filling body clustering images; V, determining a cemented filling body microcosmic porous image to obtain a cemented fillingbody microcosmic binary image; VI, obtaining a test sample image; VII, normalizing the test sample image; and VIII, inputting the normalized test sample in a pre-established Tensorflow deep learningmechanical response prediction network to obtain a three-axis mechanical response prediction result. According to the method, steps are simple, the prediction efficiency is high and functions are comprehensive, and the method has important meaning on researching strength and stability of the cemented filling body.

Owner:陕西嘉墨能源科技有限公司

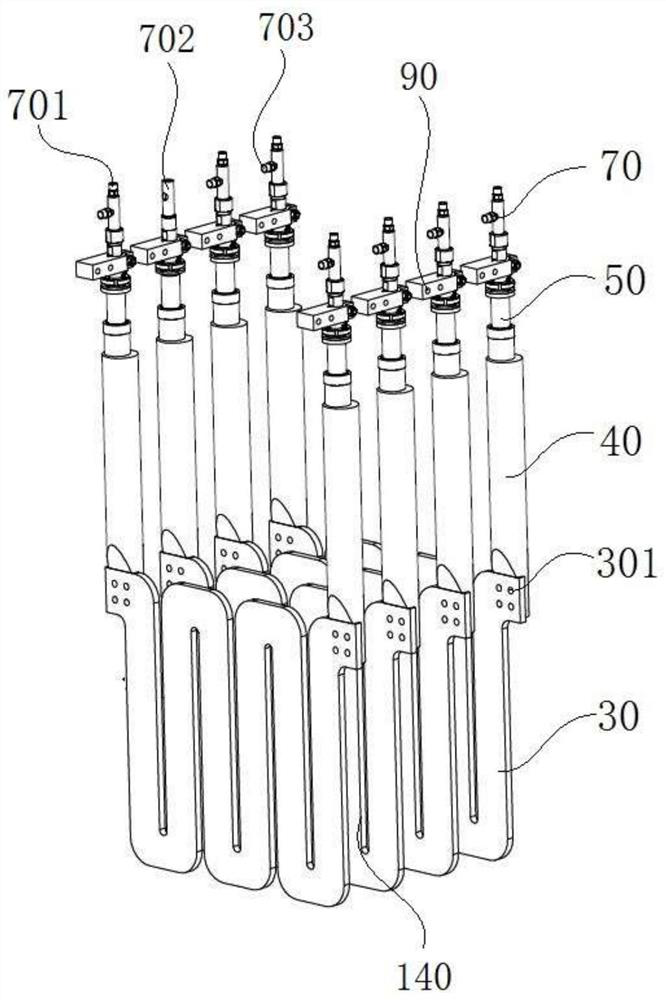

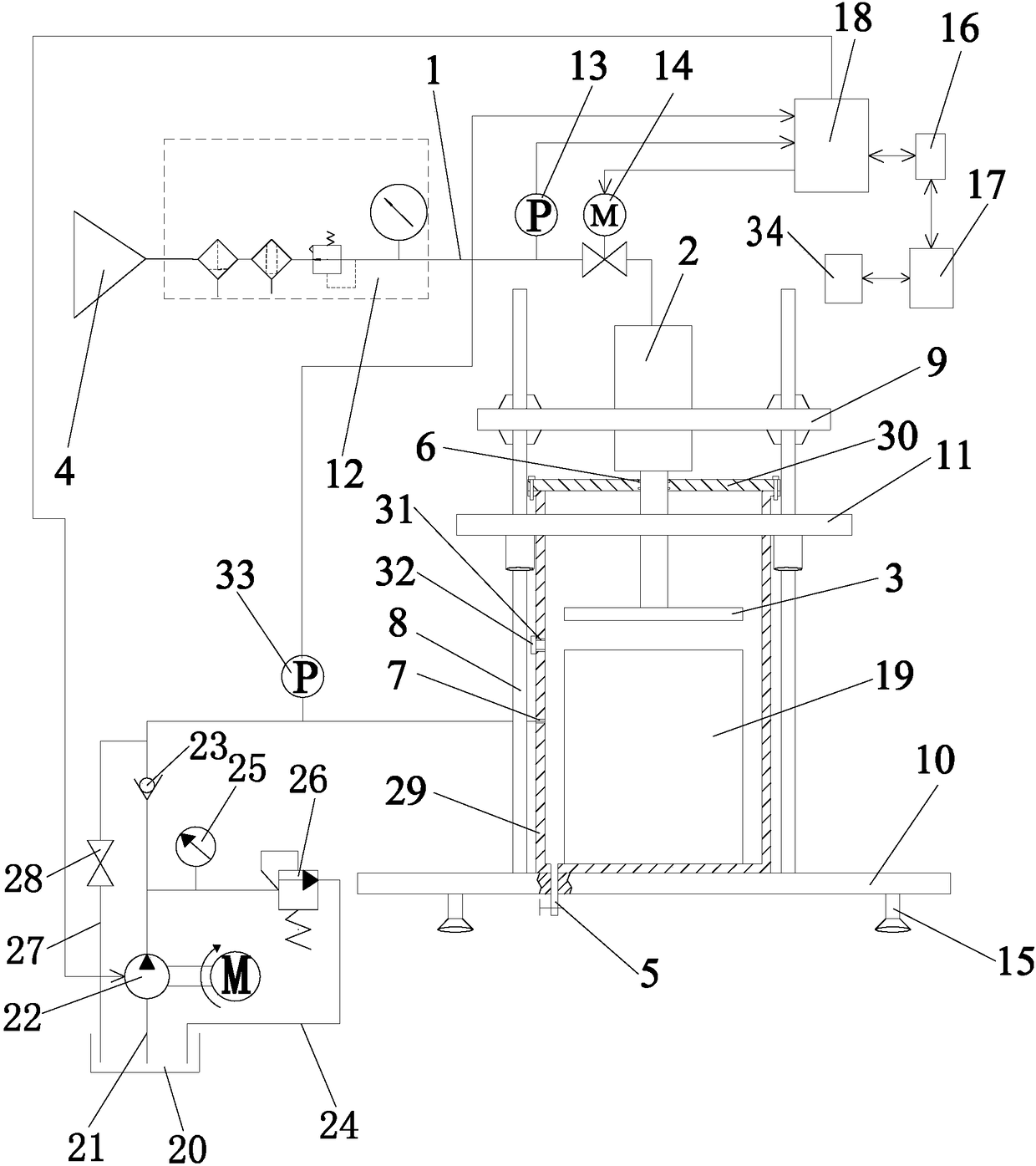

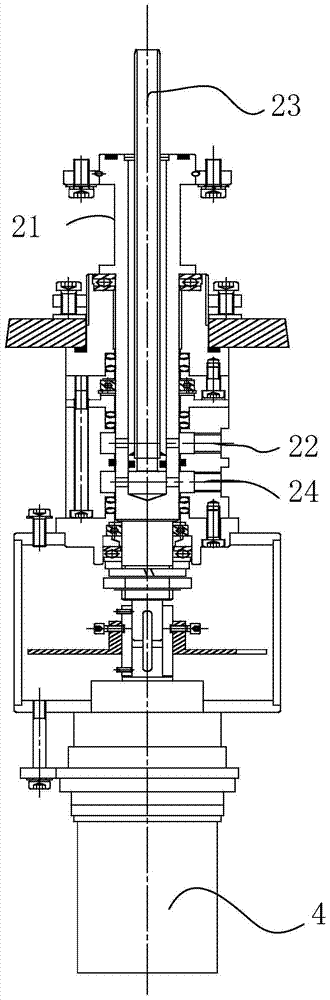

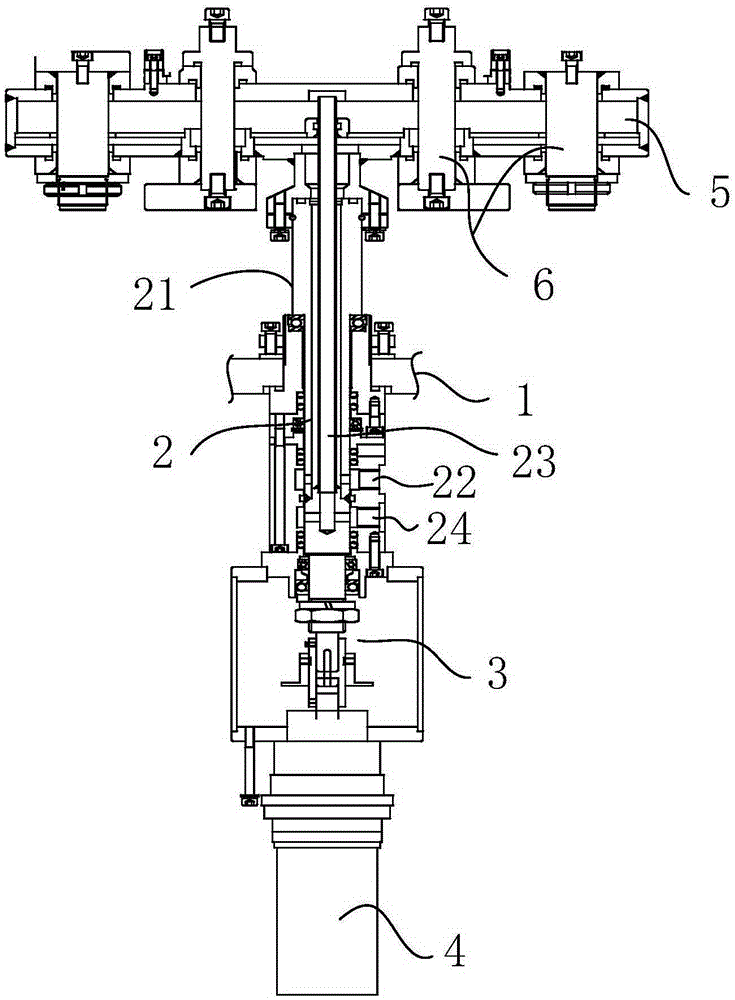

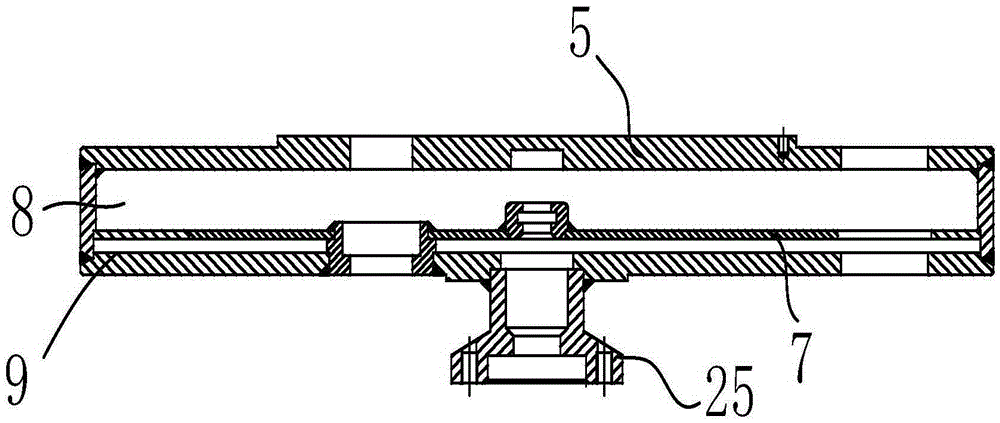

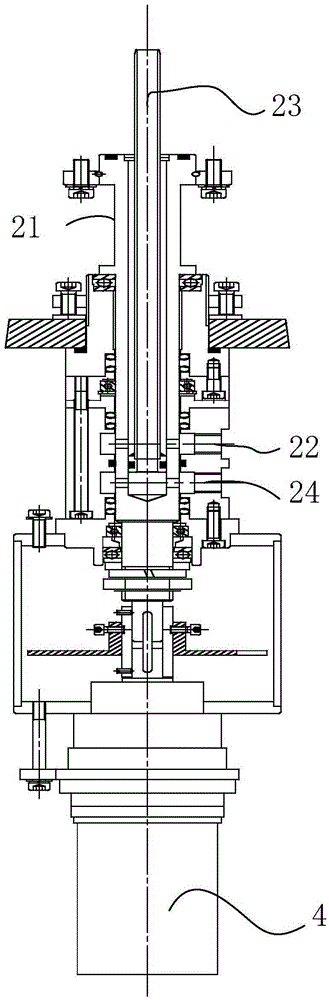

A water cooling device for vacuum evaporation equipment for optical filters

ActiveCN105296937BStable temperatureRelieve high temperatureVacuum evaporation coatingSputtering coatingMotor driveEffective length

The invention relates to a water cooling device used for vacuum evaporation equipment for optical filters. A rotating shaft is connected to a mounting and fixing plate. One end of the rotating shaft is driven and connected to a motor, and the other end is fixed to the bottom of a water cooling plate; The inner cavity of the plate is divided into an upper cavity layer and a lower cavity layer by a partition, and the upper cavity layer and the lower cavity layer are arranged in communication; a water outlet pipe is inserted into the inner cavity of the rotating shaft, and one end of the water outlet pipe extends into the water cooling plate. In the upper chamber layer, it is connected with the upper chamber layer, and the other end is connected to the water outlet of the water outlet pipe. The water inlet pipe is set on the rotating shaft. One end of the water inlet pipe is connected with the lower chamber layer of the water cooling plate, and the other end is connected to the water inlet pipe. Shuikou. In the present invention, the water outlet pipe is installed in the rotating shaft, and the water inlet pipe is set outside the rotating shaft. One end of the water outlet pipe is connected with the upper chamber layer, and one end of the water inlet pipe is connected with the lower chamber layer, effectively reducing the length of the electrode rod. The high temperature generated by working for a long time increases its service time, thereby improving work efficiency.

Owner:SUZHOU OFT OPTICAL TECH CO LTD

Water cooling device of vacuum evaporation equipment for optical filter

ActiveCN105296937ARelieve high temperatureExtended use timeVacuum evaporation coatingSputtering coatingPipingVacuum evaporation

The invention relates to a water cooling device of vacuum evaporation equipment for an optical filter. A rotating shaft is connected to a mounting and fixing plate in a penetrating manner. One end of the rotating shaft is driven by a motor and is connected with the motor, and the other end of the rotating shaft is fixed together with the bottom end of a water cooling coil. An inner cavity of the water cooling coil is partitioned into an upper cavity layer and a lower cavity layer by a partition plate, and the upper cavity layer is communicated with the lower cavity layer. A water outlet pipe is connected to the inner cavity of the rotating shaft in an inserting manner. One end of the water outlet pipe extends into the upper cavity layer of the water cooling coil and is communicated with the upper cavity layer while the other end of the water outlet pipe is communicated to a water outlet of the water outlet pipe. The rotating shaft is sleeved by a water inlet pipe. One end of the water inlet pipe is communicated with the lower cavity layer of the water cooling coil and the other end of the water inlet pipe is communicated to a water inlet of the water inlet pipe. According to the water cooling device, the rotating shaft is internally provided with the water outlet pipe, the outside of the rotating shaft is sleeved by the water inlet pipe, one end of the water outlet pipe is communicated with the upper cavity layer, and one end of the water inlet pipe is communicated with the lower cavity layer, so that high temperature generated because an electrode bar works for a long term is effectively relieved, the service life of the electrode bar is prolonged, and furthermore the work efficiency is increased.

Owner:SUZHOU OFT OPTICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com