A test system and method for mechanical response characteristics of cemented filling body

A technology of cemented filling and response characteristics, applied in the direction of strength characteristics, using stable tension/pressure test material strength, measuring devices, etc., can solve the problems of delay in mining construction period, low efficiency, high manpower and material resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

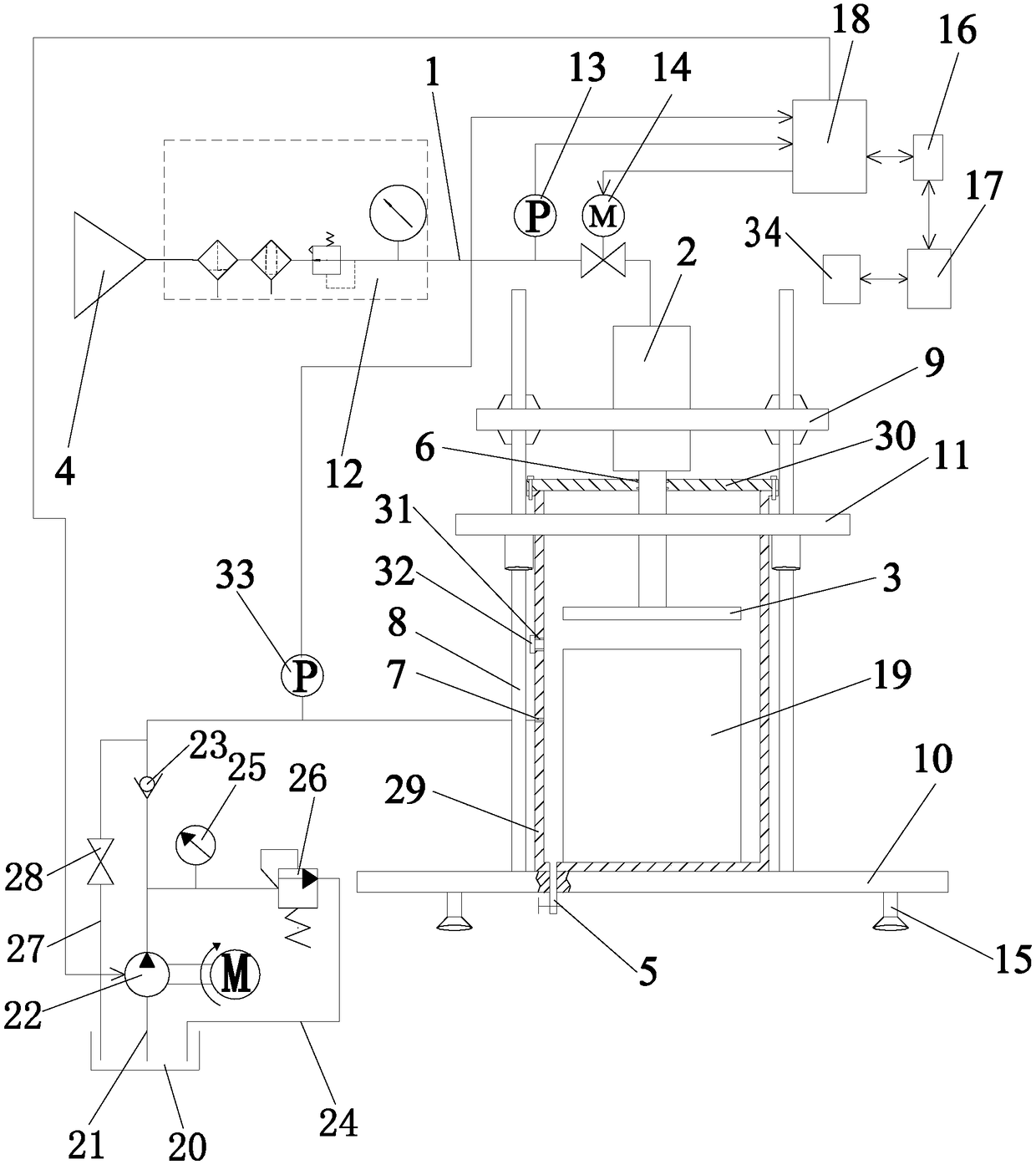

[0075] Such as figure 1 As shown, the mechanical response characteristic test system of the cemented filling body of the present invention includes a cemented filling body triaxial compressive strength testing device, a computer 17 and a SEM scanning electron microscope 34 connected to the computer 17, and the cemented filling body triaxial compressive strength The strength testing device comprises a seat cushion 10 and a plurality of pull rods 8 fixedly connected to the top of the seat cushion 10, a confining pressure loading mechanism for applying confining pressure to the cemented filling body sample, and a confining pressure loading mechanism for providing power to the confining pressure loading mechanism. The pressure loading power system, the axial pressure force transmission mechanism for applying axial pressure to the cemented filling body sample, and the axial pressure force transmission mechanism for providing power to the axial pressure force transmission mechanism; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com