Method for integrally disassembling descending movable formwork bridging machine

A technology of mobile formwork and bridge-building machines, which is applied in erecting/assembling bridges, bridges, bridge construction, etc., which can solve problems such as safety risks, high costs, cumbersome procedures, and small working space, and achieve low construction costs and methods Simple steps and reasonable design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

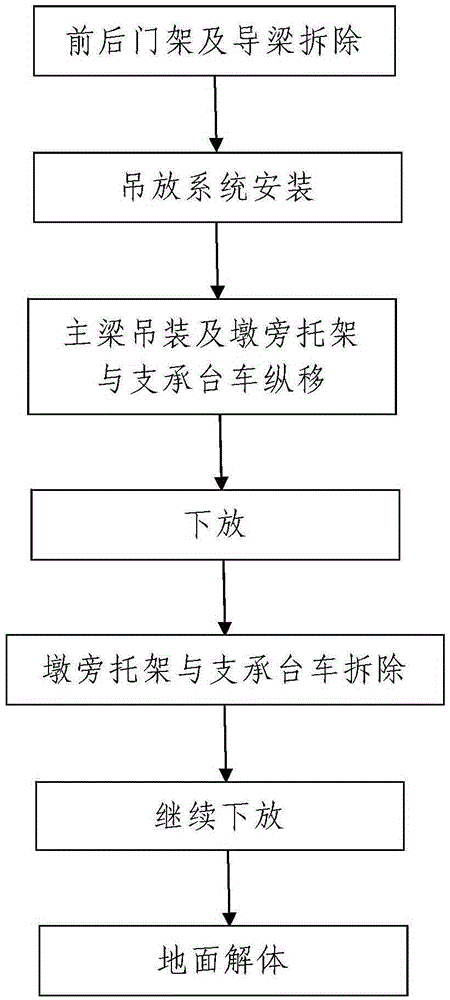

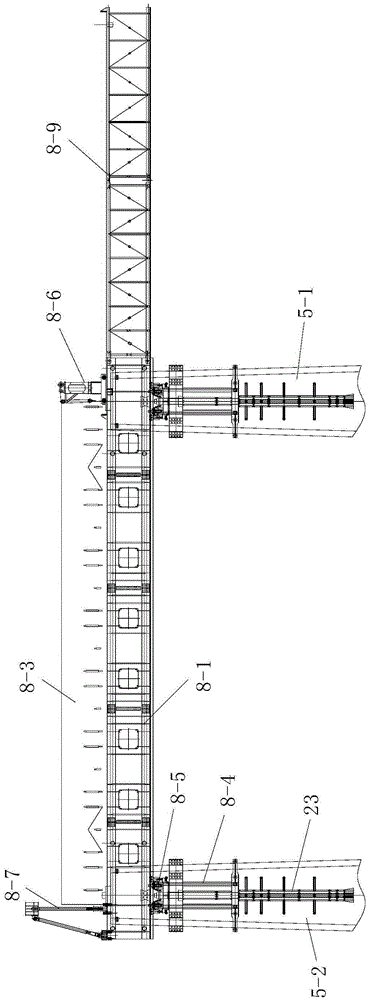

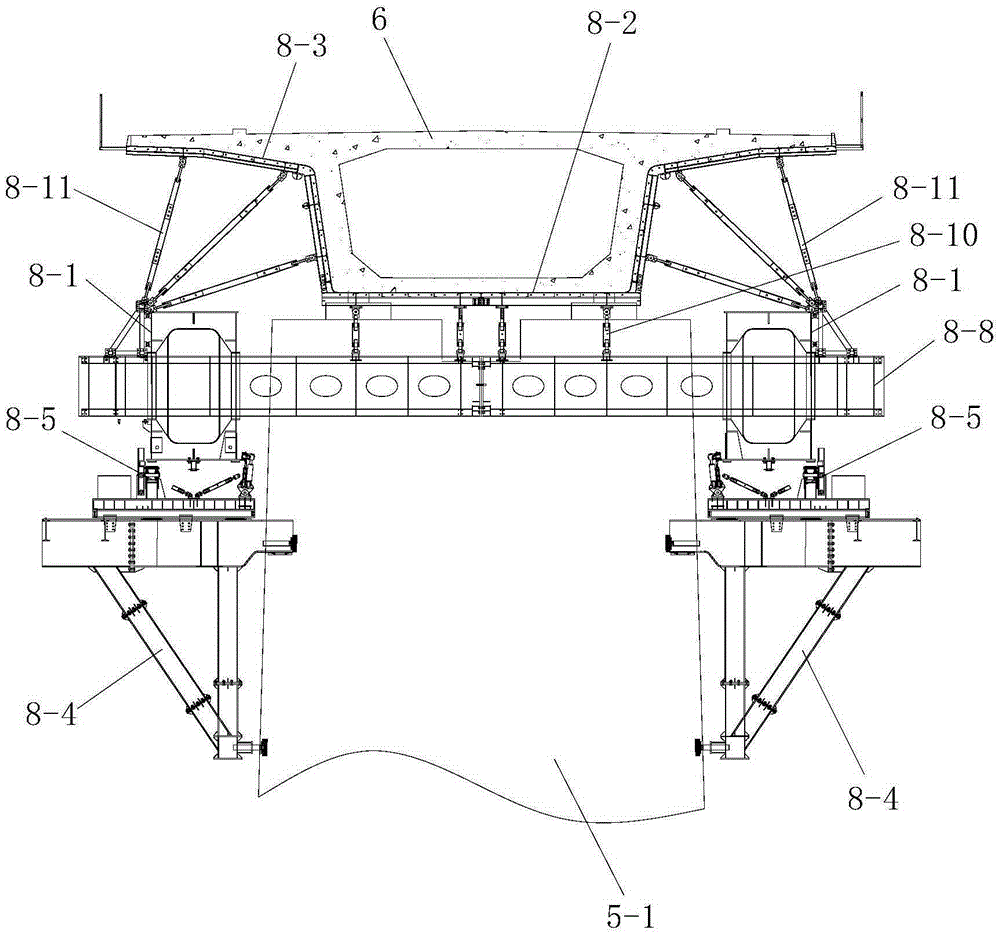

[0073] Such as figure 1 A method for overall disassembly of a downward mobile formwork bridge-building machine is shown. The disassembled mobile formwork bridge-building machine includes a bottom horizontal support system, a main girder system installed on the bottom horizontal support system, and a main girder system supported on the main beam. The outer mold system on the beam system and the front door frame 8-6 and the rear door frame 8-7 respectively installed above the front and rear ends of the main beam system. The main beam 8-1 on the system and multiple connecting beams 8-8 are connected between the two main beams 8-1 from front to back, and the front sides of the two main beams 8-1 are equipped with guide rails. Beams 8-9, the two main beams 8-1 are connected by multiple connecting beams 8-8, see figure 2 and image 3 The bottom horizontal support system includes two groups of front and rear pier side brackets 8-4 respectively fixed on the front side pier 5-1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com