A standard modular component for building and a prefabricated building containing it

A standard module, construction technology, applied in construction, building construction, etc., can solve the problems of self-heavy prefabricated structure, high manual operation requirements, limited processing accuracy, etc., to improve on-site installation efficiency, facilitate on-site assembly, Overall cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 Building Standard Modular Assembly

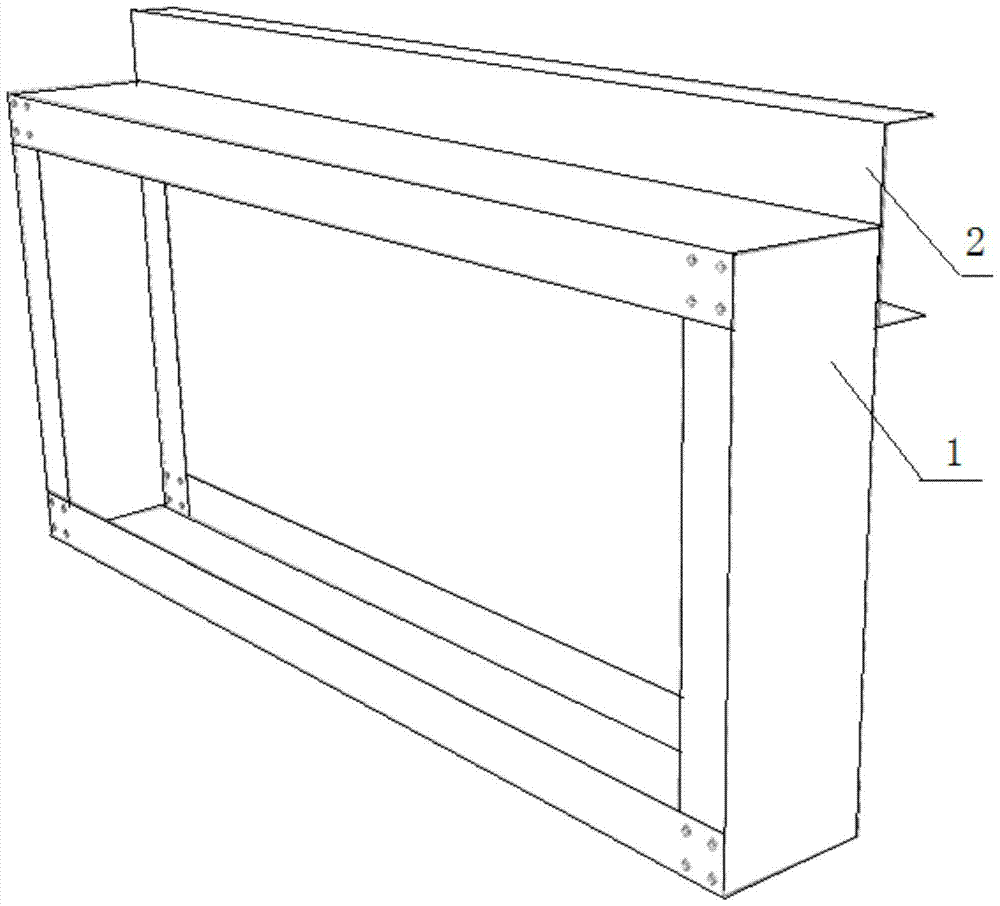

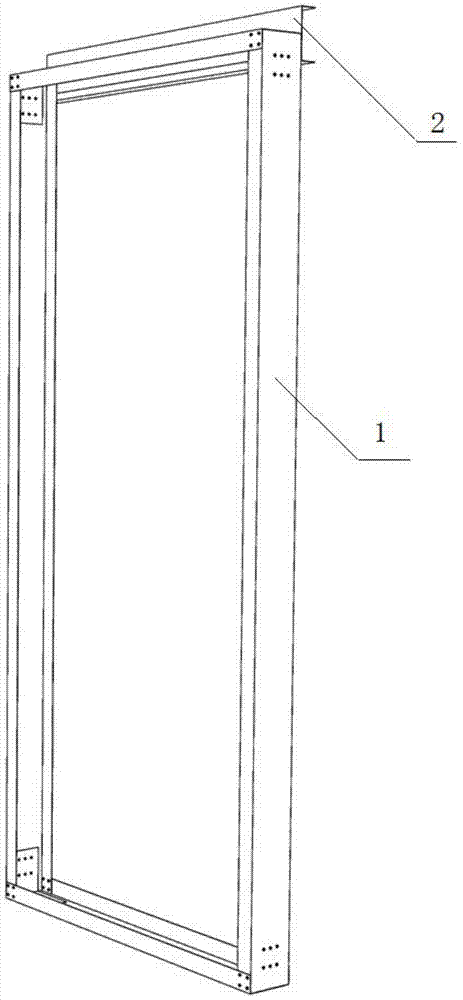

[0057] Such as figure 1 , 2 As shown, a standard modular assembly for construction in this embodiment includes a frame body 1 and an external C-shaped steel member 2; wherein the outer frame of the frame body 1 is in the shape of a square; The non-surrounding outside, and in its length direction, is connected with one side of the outer frame of frame body 1, and partly protrudes out of frame body 1 outside in its width direction.

[0058] The preferred scheme is that the above-mentioned square-shaped outer frame is composed of 4 C-shaped steel members connected together, and the C-shaped openings of the 4 C-shaped steel members face into the frame. The connections between the C-shaped steel members are bolted. The above four C-shaped steel members and the external C-shaped steel member 2 are preferably cold-formed thin-walled steel.

[0059] The above-mentioned standard modular components for construction are divided...

Embodiment 2

[0065] Embodiment 2 Contains the prefabricated building of building standard modular components

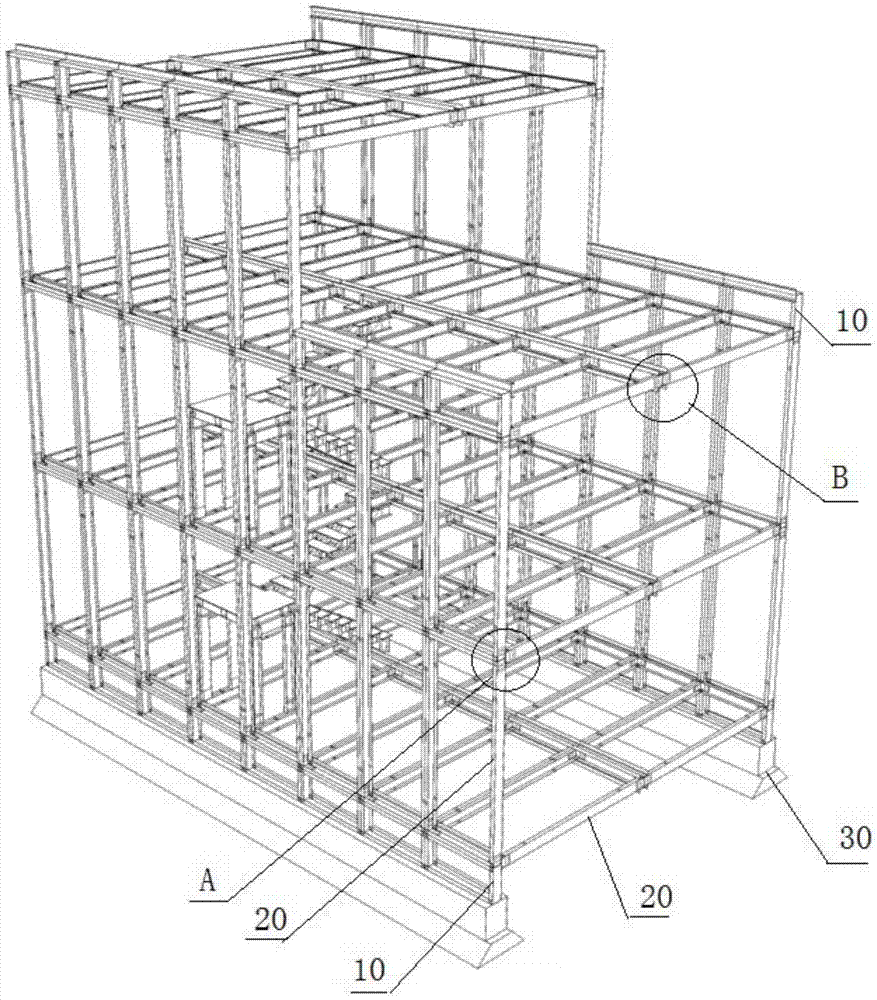

[0066] A prefabricated building in this embodiment includes a building structure frame assembled from the standard modular components for building in Embodiment 1.

[0067] The following is a detailed description by taking the preferred building standard modular components (divided into two types, the first component and the second component) in Embodiment 1 as an example.

[0068] Specific as Figure 3-5 As shown, a prefabricated building also includes two strip foundations 30 supporting the structural frame of the building; the ground floor of the first floor of the building adopts a raised floor method instead of a ground method.

[0069] The vertical side wall of the lowermost layer of the above-mentioned prefabricated building is composed of a plurality of first components 10 fixedly connected to the strip foundation 30. The external C-shaped steel members of the first compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com