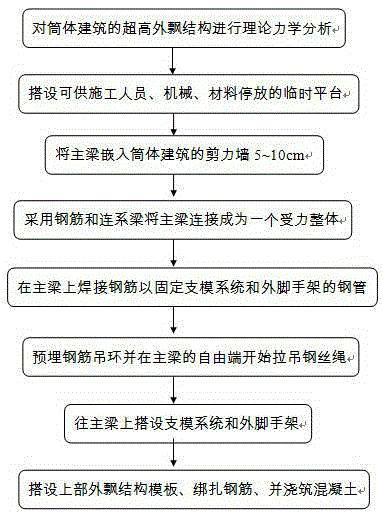

Construction method of cantilever construction platform with ultrahigh cast-in-place flaring structure in cylindrical building

A technology of construction platform and construction method, applied in building structure, scaffolding supported by house structure, construction, etc., can solve the problems of long inner anchor distance, increased cost, unfavorable economic benefits, etc., and achieve stable construction, quality assurance, Significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

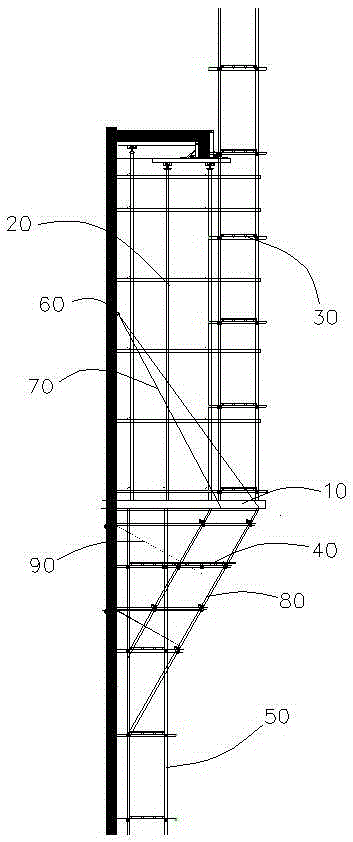

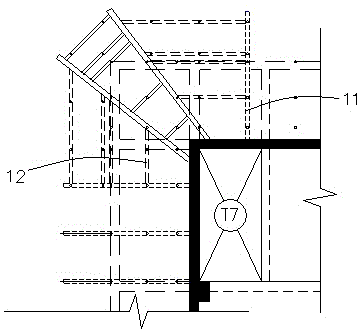

Examples

Embodiment

[0032] Taking the 20-story floating structure of the cylinder building of the elevator test tower as an example, the construction technology of erecting a cantilevered construction platform is studied. The basic overview of the cylindrical building is: the total construction area is 18333m 2 , The total building height is 99.8m, with 21 floors above ground, 3 podium floors and 2 floors underground. The tower is a shear wall structure, the interior is an elevator shaft or stairs, and the 20th floor is an outer floating structure layer. The cantilevered steel supports are erected to support the upper load and the outer scaffolding enclosure. The main function of the elevator test tower construction project is as a cylindrical building for testing the performance of the elevator. The interior of the building is mainly the opening of the elevator shaft, and there is not enough space around it for anchoring the extended I-beam. For the construction of the cantilevered construction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com