Secondary reheating ultra-supercritical unit improved through subcritical coal-fired power generation unit

A technology of ultra-supercritical units and generating units, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve problems such as large-scale difficulties and improve the energy efficiency of units, so as to improve energy efficiency, realize industrial upgrading, and scientific layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0020] Example.

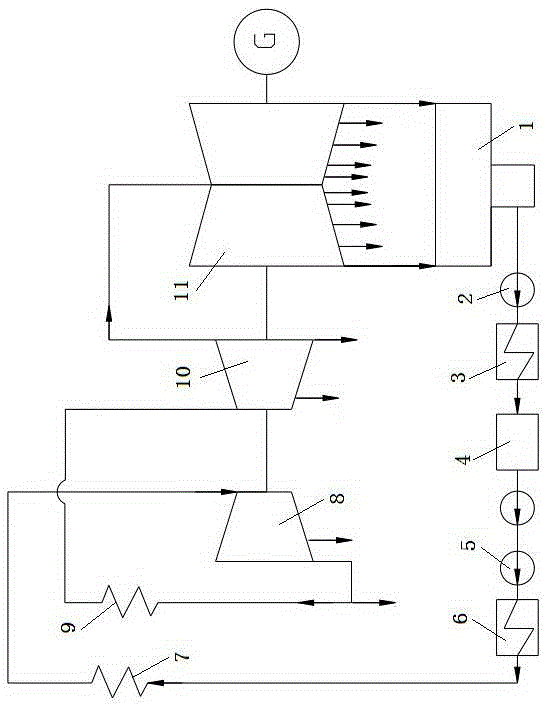

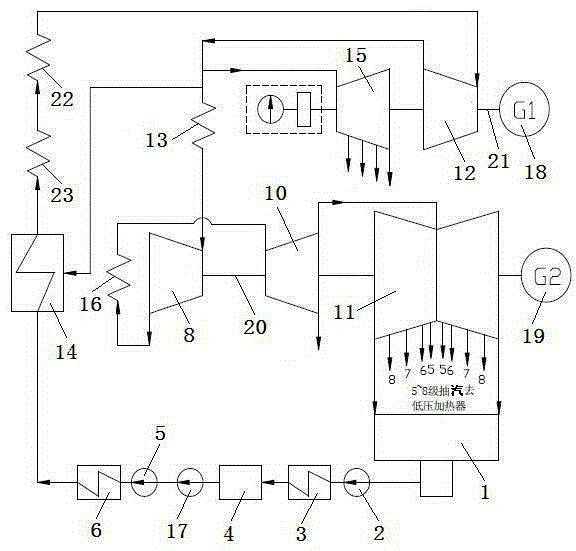

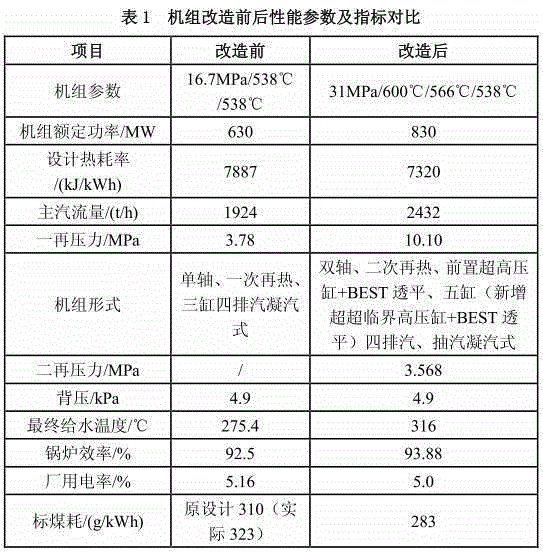

[0021] see figure 2 In this embodiment, the double reheated ultra-supercritical unit transformed with subcritical coal-fired generator set includes condenser 1, condensate pump 2, four-stage low-pressure heater 3, deaerator 4, feed water pump 5, and three-stage High-pressure heater 6, ultra-supercritical boiler superheater 22, ultra-supercritical boiler economizer 23, high-pressure cylinder 8, medium-pressure cylinder 10, low-pressure cylinder 11, ultra-supercritical back pressure machine 12, ultra-supercritical boiler primary reheat device 13, No. 0 high-pressure heater 14, back pressure extraction turbine 15, ultra-supercritical boiler secondary reheater 16, front pump 17, small generator 18 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com