Dynamic pressure bearing and fan structure using dynamic pressure bearing and assembling method thereof

A technology of dynamic pressure bearings and bearings, applied in the field of dynamic pressure bearings, which can solve problems such as the deflection of the rotation axis of the rotating shaft 6 fan blades, the easy wear of the rotating shaft, and the reduction of the bearing area of the oil film, so as to reduce the vibration and noise of the fan operation and improve the operation The effect of stability and large oil film bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example 〕

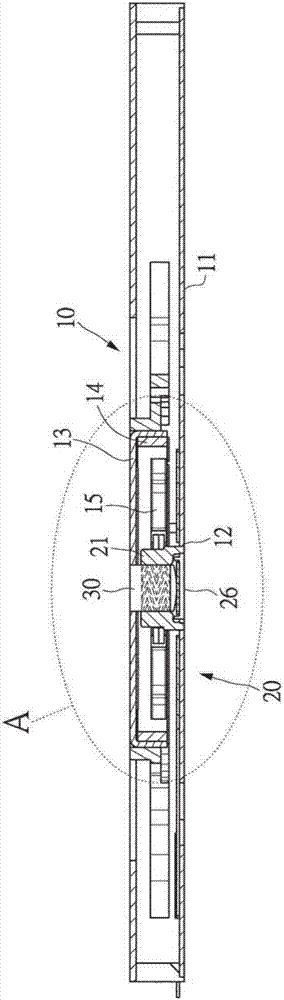

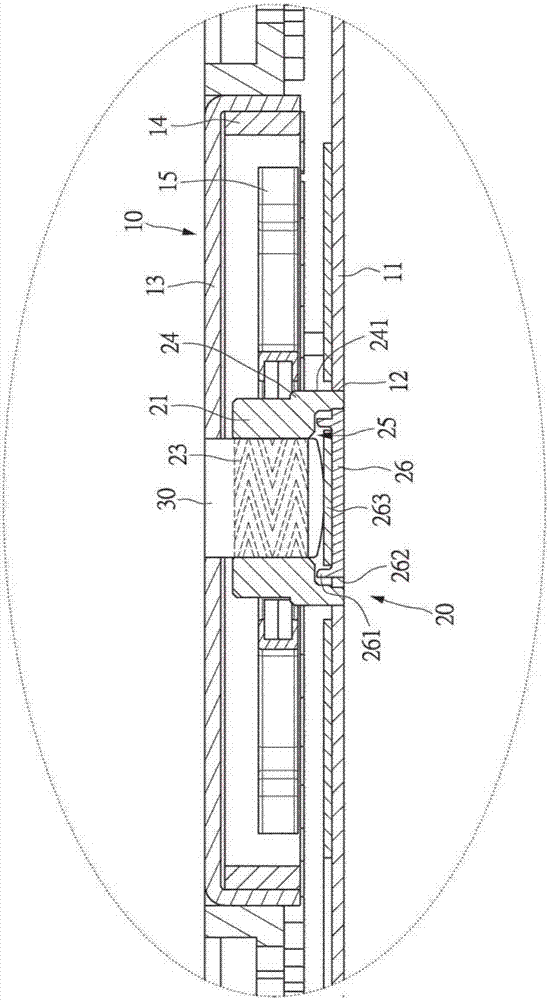

[0081] The present invention provides a dynamic pressure bearing and a fan structure using the dynamic pressure bearing, such as figure 1 Shown is a combined sectional view of a fan structure 10 using the dynamic pressure bearing of the present invention, wherein the fan structure 10 includes a bottom plate 11 , a fan blade 13 , a rotor 14 , a stator 15 and a dynamic pressure bearing assembly 20 .

[0082] The dynamic pressure bearing assembly 20 is installed on a fixed seat 12 on the bottom plate 11 , and the fan blade 13 is installed on the upper end of a rotating shaft 30 of the dynamic pressure bearing assembly 20 . The stator 15 is fixedly installed on the outer side of the dynamic pressure bearing assembly 20 , and the rotor 14 is installed on the inner side of the fan blade 13 and surrounds the outer side of the stator 15 . The rotor 14 and the stator 15 can generate mutually repulsive magnetic fields to drive the fan blades 13 to rotate.

[0083] Such as figure 2 A...

no. 2 example

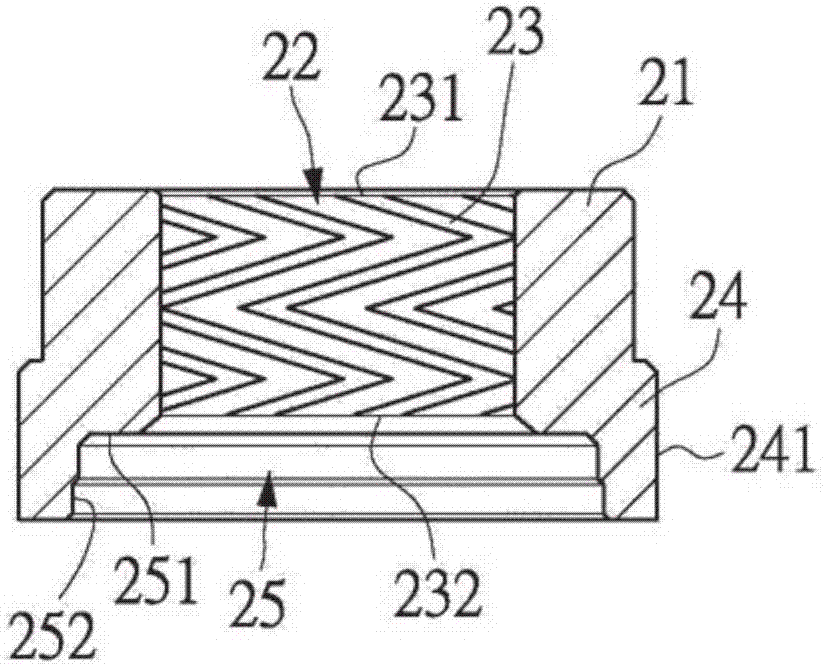

[0106] Such as Figure 8 Shown is the second embodiment of the present invention, and the second embodiment is an embodiment in which the technology of the present invention is applied to a thick heat dissipation fan module. The fan structure 10 and the dynamic pressure bearing assembly 20 in this embodiment have higher heights, and the heights of the bearing body 21 and the rotating shaft 30 are also higher than those of the bearing body 21 and the rotating shaft 30 in the first embodiment. In the second embodiment, the shaft hole 22 of the bearing body 21 has more than one row of oil guide grooves 23 inside.

[0107] Such as Figure 8 In the shown embodiment, the inner wall surface of the shaft hole 22 of the bearing body 21 is arranged along the axial direction of the shaft hole 22 with two rows of oil guide grooves 23, and an isolation groove is arranged between the two rows of oil guide grooves 23 233 isolates the two rows of oil guide grooves 23. The function of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com