Piezoelectric-type flexible three-dimensional tactile sensing array and preparation method of same

A tactile sensing and piezoelectric technology, which is applied in the field of flexible three-dimensional tactile sensing arrays, can solve the problems of inability to contact and quickly respond to slip signals, inability to arrange fingers in a curved surface array, and inability to bend at will. Easy to operate and easy to load on curved surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

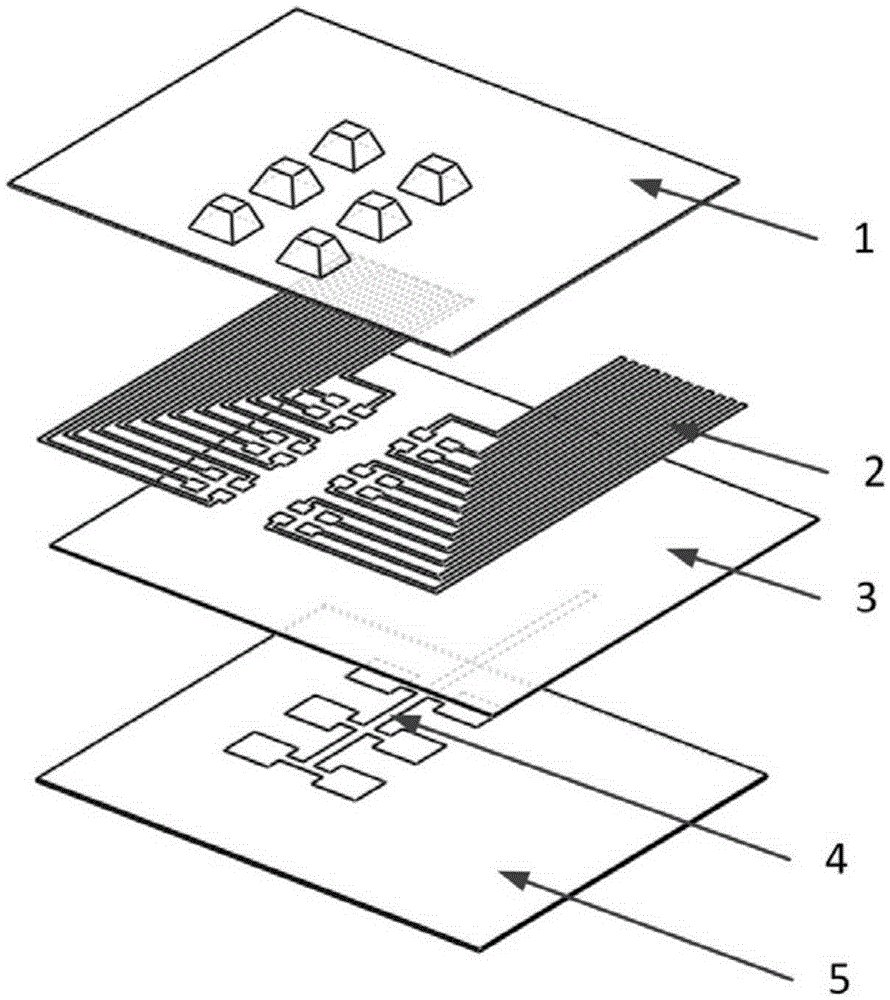

[0030] Such as figure 1 As shown, the flexible three-dimensional tactile sensing array of the present invention consists of a PDMS surface convex layer 1, an upper electrode layer 2, a PVDF piezoelectric film layer 3, a lower electrode layer 4, and a PDMS flexible substrate layer 5 from top to bottom. composed together. Among them, the convex layer 1 on the PDMS surface plays the role of transmitting the contact force, and at the same time isolates the upper electrode layer 2 from the outside world to reduce interference; the PVDF piezoelectric film layer 3 forms a piezoelectric Capacitance converts the force signal into a charge signal; the PDMS flexible base layer 5 isolates the lower electrode layer 4 from the outside, protects the lower electrode layer and isolates external interference.

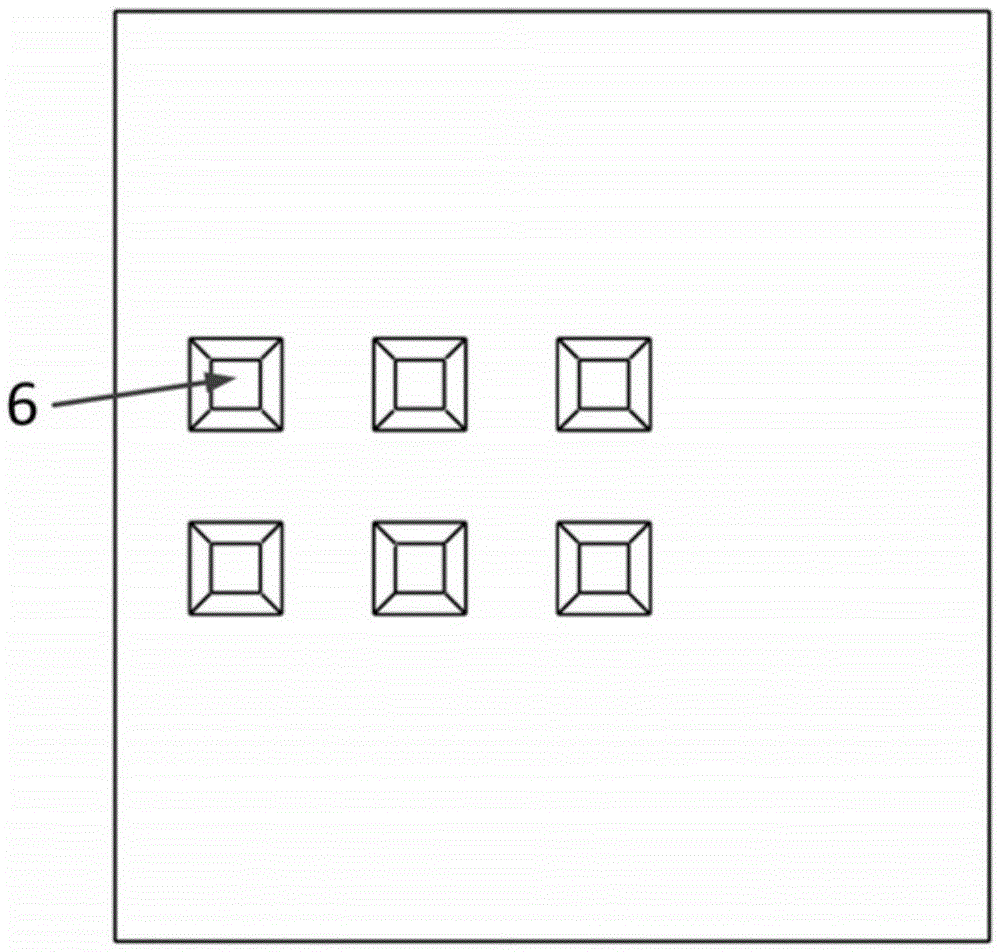

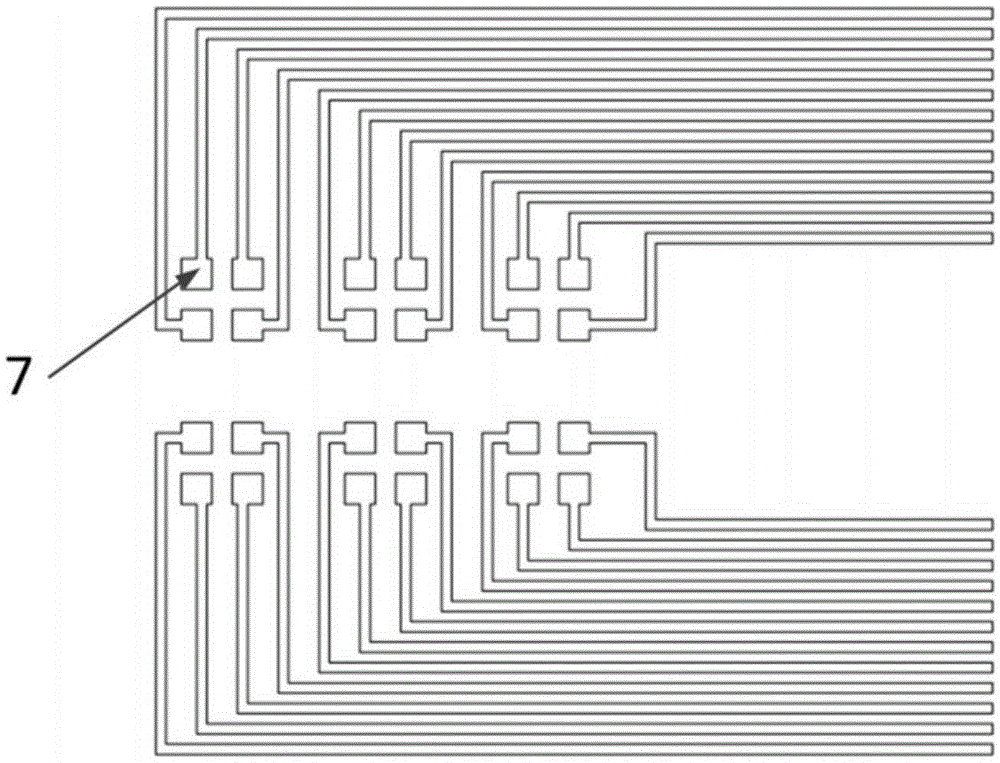

[0031] Such as figure 2 , image 3 , Figure 4 As shown, the PDMS surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com