Fault diagnosis method for weight-loss fly ash carbon content on-line detection device

A fly ash carbon content and detection device technology, which is applied in the direction of removing certain components and weighing, etc., to achieve the effects of improving reliability and service life, ensuring continuity, and reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the drawings and embodiments.

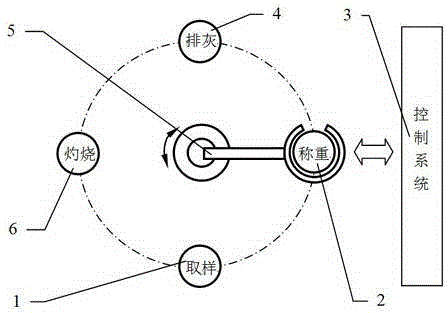

[0023] In this embodiment, the analytical balance of the original detection device weighing station 2, the control system 3, the actuators of each station (1, 4, 5, 6) and their positioning sensors or angle sensors are used. The control system uses an industrial programmable controller (PLC), the positioning sensor uses a Hall proximity switch, and the angle sensor uses a high-resolution encoder.

[0024] The specific implementation process is as follows:

[0025] 1. Monitoring and judgment of the collision fault between the cantilever and each station

[0026] Process a connecting piece of insulating material to insulate and connect the cantilever on the cantilever mechanism 5 with its base, and draw a wire from the cantilever; then draw another wire on the metal platform where the components of each station (1, 2, 4, 6) are fixed. One wire. Connect the two wires to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com