Low-temperature environment-friendly conductive silver paste and its preparation method and application

A conductive silver paste, environmentally friendly technology, applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of poor conductivity, poor adhesion between conductive silver paste and substrates, etc. Achieve high conductivity, easy control of process conditions, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Correspondingly, on the basis of the aforementioned low-temperature environmentally friendly conductive silver paste, the embodiment of the present invention also provides a method for preparing the low-temperature environmentally friendly conductive silver paste of the present invention. In one embodiment, the preparation method of the low-temperature environmentally friendly conductive silver paste includes the following steps:

[0031] S01: Weigh each component according to the components contained in the low-temperature environmentally friendly conductive silver paste of the present invention;

[0032] S02: Perform a first mixing process on the weighed organic carrier and the flaky silver powder to prepare a first mixture;

[0033] S03: Perform a second mixing process on the weighed ultrafine silver and the first mixture to prepare a second mixture;

[0034] S04: Perform a third mixing process on the weighed additive and the second mixture to prepare a third mixture;

[0035...

Embodiment 1

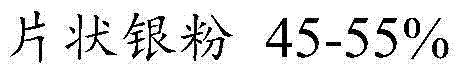

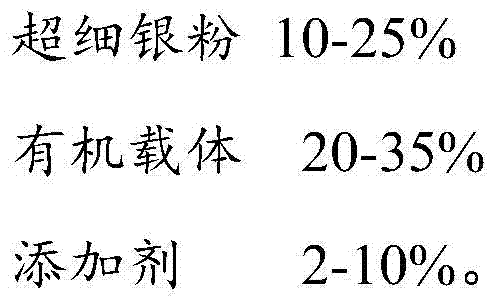

[0045] This embodiment provides a low-temperature environment-friendly conductive silver paste, which is composed of an organic carrier, flake silver powder, ultrafine silver powder, silane coupling agent and putty powder.

[0046] The preparation method is as follows:

[0047] S11: Weigh 10g of polyester resin and dissolve it in 45g of propylene glycol methyl ether acetate, heat it at a constant temperature at 60°C and stir until it is completely dissolved, filter and cool to obtain an organic carrier;

[0048] S12: Weigh 55g of flake silver powder with an average size of 2μm and dissolve it into the aforementioned 28g organic carrier, stir it with a mixer until it is evenly mixed to obtain a silver powder mixture (1); weigh 25g of ultrafine silver powder with an average particle size of 20nm and add it to the The silver powder mixture (1) is fully stirred with a mixer until the mixture is uniform to obtain the silver powder mixture (2).

Embodiment 2

[0053] This embodiment provides a low-temperature environment-friendly conductive silver paste, which is composed of an organic carrier, flake silver powder, ultrafine silver powder, silane coupling agent and putty powder.

[0054] The preparation method is as follows:

[0055] S21: Weigh 10 g of polyester resin and dissolve it in 35 g of ethylene glycol ethyl ether acetate solvent, heat and stir at a constant temperature at 60° C. until it is completely dissolved, and obtain an organic carrier through filtration and cooling.

[0056] S22: Weigh 48g of flaky silver powder with an average size of 2μm and dissolve it into the aforementioned 32g of organic carrier, stir thoroughly with a blender until the mixture is mixed to obtain a silver powder mixture (1); weigh 18g of ultrafine silver powder with an average particle size of 20nm and add it to The silver powder mixture (1) is fully stirred with a mixer until the mixture is uniform to obtain the silver powder mixture (2).

[0057] S23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com