A kind of preparation method of phthalocyanine blue pigment

A technology for phthalocyanine blue and pigments, which is applied in the field of preparation of phthalocyanine blue pigments, can solve the problems of poor pigment coloring power and dispersion performance, large energy consumption, and many processing procedures, and achieve good dispersibility and coloring power and shorten the production time. Process flow and the effect of avoiding dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

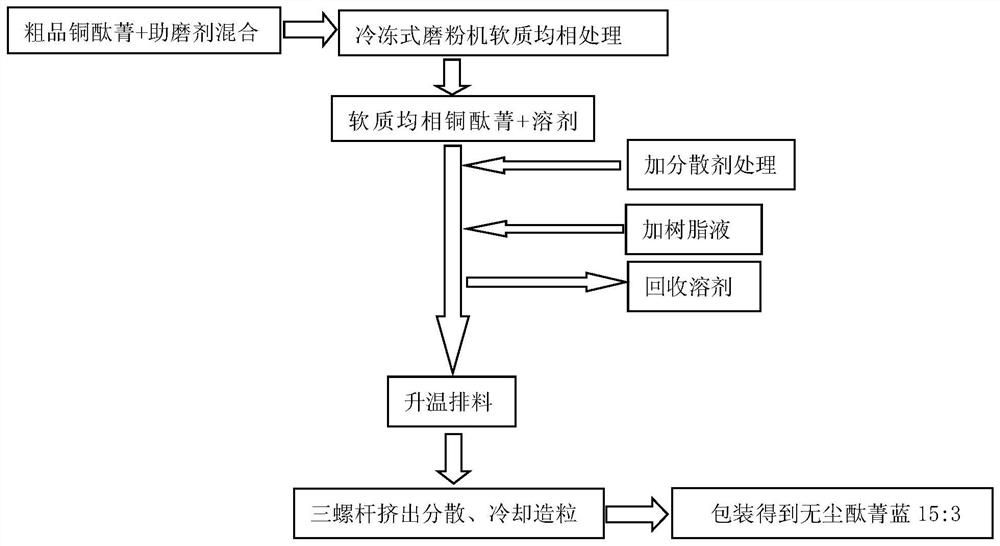

Method used

Image

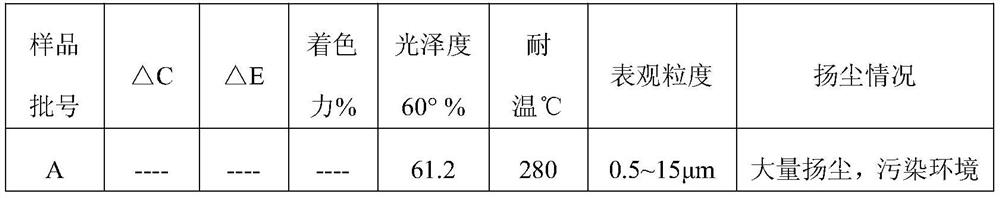

Examples

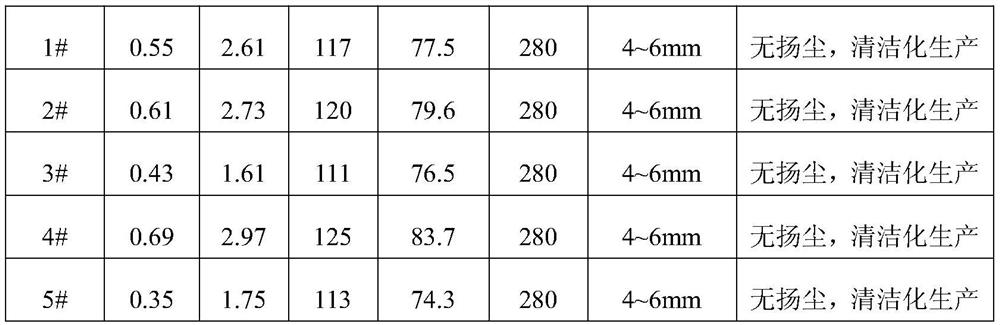

Embodiment 1

[0029] Embodiment 1: the preparation of phthalocyanine blue pigment

[0030] (1) The crude product copper phthalocyanine is synthesized by the solvent method, and 510kg crude product copper phthalocyanine and 11kg granular nano-calcium are mixed, dispersed, and ground in a refrigerated mill to obtain a homogeneous copper phthalocyanine; the refrigerated mill The working temperature of the powder machine is 115°C, the discharge temperature of homogeneous copper phthalocyanine is 95°C, and the discharge particle size D90≤5μm;

[0031] (2) Transfer the homogeneous copper phthalocyanine into the distillation reaction kettle, add 1800LTHF, feed nitrogen to protect the reaction until the end, and reflux at 65°C for 1.5 hours to obtain the homogeneous β crystal phthalocyanine blue;

[0032] (3) Add 10.88 g of unsaturated polycarboxylic acid polymer, 0.37 kg of polysiloxane copolymer, and 3.75 kg of titanate coupling agent to the homogeneous β crystal phthalocyanine blue several times...

Embodiment 2

[0035] Embodiment 2: the preparation of phthalocyanine blue pigment

[0036] (1) The crude product copper phthalocyanine is synthesized by the solvent method, and the 510kg crude product copper phthalocyanine and 12kg granular nano-calcium are mixed, dispersed, and ground in a refrigerated mill to obtain a homogeneous copper phthalocyanine; the refrigerated mill The working temperature of the powder machine is 110°C, the discharge temperature of homogeneous copper phthalocyanine is 90°C, and the discharge particle size D90≤5μm;

[0037](2) Transfer the homogeneous copper phthalocyanine into the distillation reaction kettle, add 1800LTHF, pass through the nitrogen gas to protect the reaction until the end, and reflux at 65°C for 2 hours to obtain the homogeneous β crystal phthalocyanine blue;

[0038] (3) Add 13.05 kg of unsaturated polycarboxylic acid polymer, 0.45 kg of polysiloxane copolymer, and 4.5 kg of titanate coupling agent to the homogeneous β crystal phthalocyanine b...

Embodiment 3

[0041] Embodiment 3: the preparation of phthalocyanine blue pigment

[0042] (1) The crude product copper phthalocyanine is synthesized by the solvent method, and 510kg crude product copper phthalocyanine and 13kg granular nano-calcium are mixed, dispersed, and ground in a refrigerated mill to obtain a homogeneous copper phthalocyanine; the refrigerated mill The working temperature of the powder machine is 108°C, the discharge temperature of homogeneous copper phthalocyanine is 90°C, and the discharge particle size D90≤5μm;

[0043] (2) Transfer the homogeneous copper phthalocyanine into the distillation reaction kettle, add 1800LEAC, pass through nitrogen to protect the reaction until the end, and reflux at 76°C for 2.5 hours to obtain the homogeneous β crystal copper phthalocyanine;

[0044] (3) Add 14.5 kg of unsaturated polycarboxylic acid polymer, 0.5 kg of polysiloxane copolymer, and 5 kg of titanate coupling agent to the homogeneous β crystal copper phthalocyanine sever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com