A heavy rare earth high performance NdFeB permanent magnet and its manufacturing method

A technology without heavy rare earths and permanent magnets, which is applied in the manufacture of inductors/transformers/magnets, magnetic objects, magnetic materials, etc., can solve the problems of high prices and decreased reserves of heavy rare earths, and achieve the effect of reducing consumption and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Prepare raw materials:

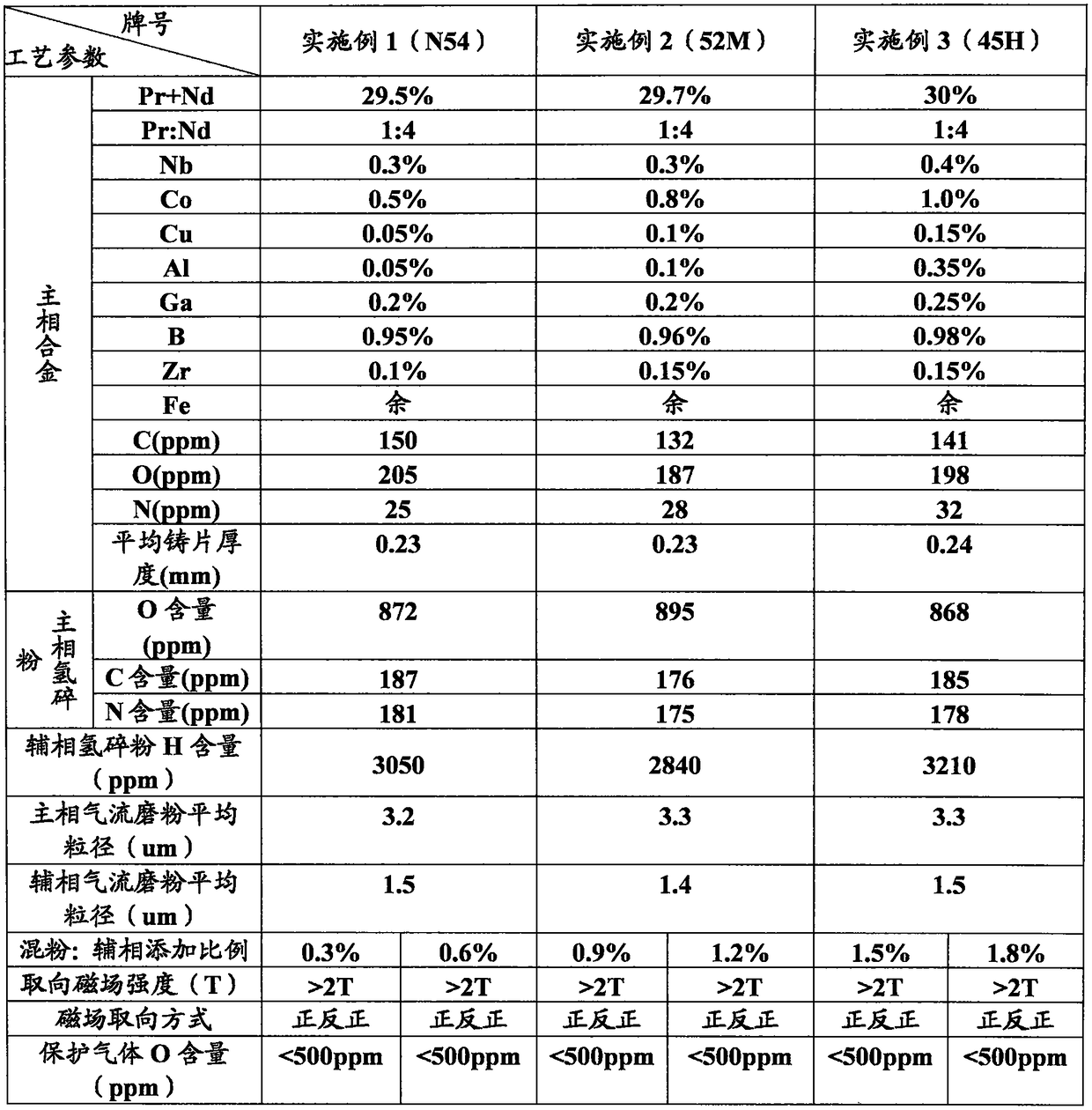

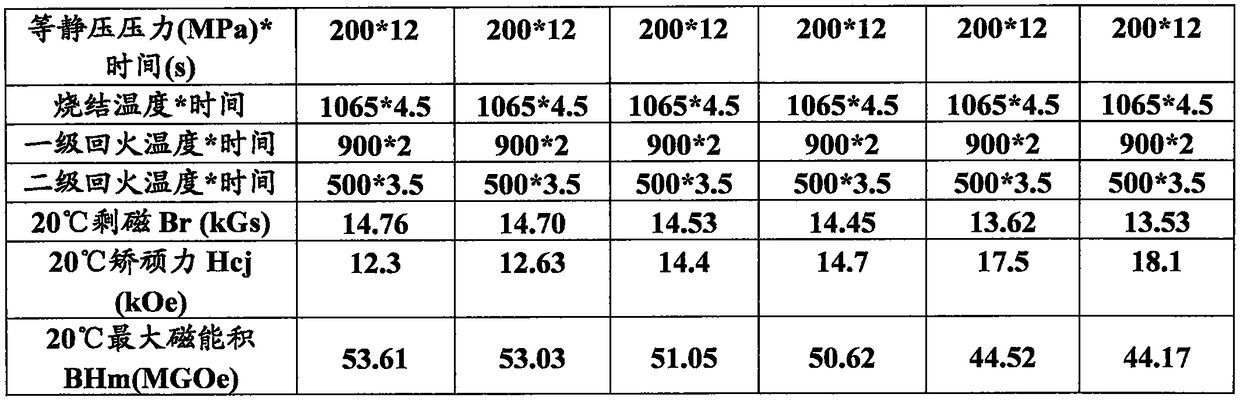

[0058] (A) The main phase alloy, Pr:Nd is preferably 1:4, and its composition is shown in Table 1.

[0059] (B) The auxiliary phase metal is a PrNd alloy hydride.

[0060] 1) Preparation of the main phase alloy cast sheet: the raw materials in the main phase alloy are placed in a crucible in order according to the melting point, and after 20 minutes in the oven, vacuumize to below 3Pa, fill with argon to 30Mpa under pressure protection, and heat up to 1500°C for melting The alloy was cast for 10 minutes, and the temperature was lowered to 1400° C. to obtain a main phase alloy cast sheet with an average thickness of about 0.25 mm.

[0061] 2) Preparation of main phase alloy hydrogen crushing powder: the main phase alloy is crushed to a block shape smaller than 30mm*15mm. When hydrogen is crushed, hydrogen is fully absorbed. The alloy can be put into the hydrogen crushing furnace and heated to 250°C before feeding Hydrogen reaction. During dehydr...

Embodiment 2-3

[0072] Prepare permanent magnets according to the same method as in Example 1, wherein the auxiliary phase metals used are respectively Nd hydrides (in Example 2) and PrNd alloy hydrides (in Example 3), and the process parameters and results are listed in Table 1 .

[0073] Table 1

[0074]

[0075]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com