Process monitoring method after etching semiconductor deep hole

A semiconductor and deep hole technology, applied in the field of process monitoring after semiconductor deep hole etching, can solve the problems of slow feedback results, wafer destructiveness, and inability to effectively monitor the process, and achieve the effect of intuitive feedback results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

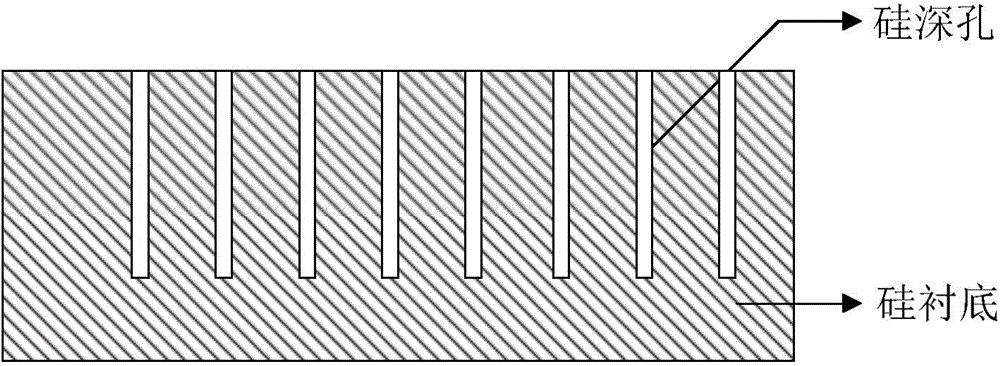

[0023] The invention provides a process monitoring method after semiconductor deep hole etching, adopts a non-damaging high-precision quality measurement method to indirectly characterize whether the silicon deep hole etching depth meets the process requirements, is fast, accurate and does not damage the wafer structure. In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] The following disclosure provides many different embodiments or examples for implementing different structures of the present invention. To simplify the disclosure of the present invention, components and arrangements of specific examples are described below. Of course, they are only examples and are not intended to limit the invention. In addition, various specific process and material examples are provided herein, but one of ordinary s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com