A method for manufacturing an ultra-thin vapor chamber as a heat sink material

A manufacturing method and technology of heat sink materials, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of increased geometric size and weight, structural change, contact failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

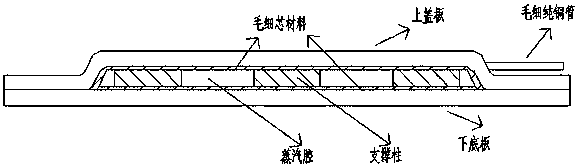

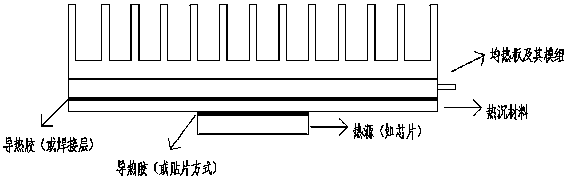

[0026] An ultra-thin soaking heat sink material made of ultra-thin foam copper and ultra-thin molybdenum-copper or tungsten-copper alloy through structural design, high-temperature sintering, welding, packaging liquid injection, etc. The implementation method and specific steps of the vapor chamber are as follows, which is divided into two aspects: one is the selection and design of the upper cover plate and the lower bottom plate of the vapor chamber; the other is the design of the liquid-absorbing core and its structure inside the vapor chamber, such as Figure 4 shown.

[0027] One is the selection and design of the cover plate and the bottom plate on the soaking plate:

[0028] (1) The upper cover plate is usually made of oxygen-free pure copper, which is deformed by a small amount of stamping, and the deformation amount is the thickness of the added foamed copper;

[0029] (2) The lower bottom plate adopts heat sink material such as molybdenum copper alloy or tungsten copp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com