Fully-intelligent variable-temperature chelating reactor

A chelation reaction and intelligent technology, which is applied in the field of fully intelligent temperature-variable chelation reactors, can solve the problems of reducing product quality, high labor intensity, and low precision, and achieve the effects of accelerating reaction speed, improving product quality, and increasing product output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

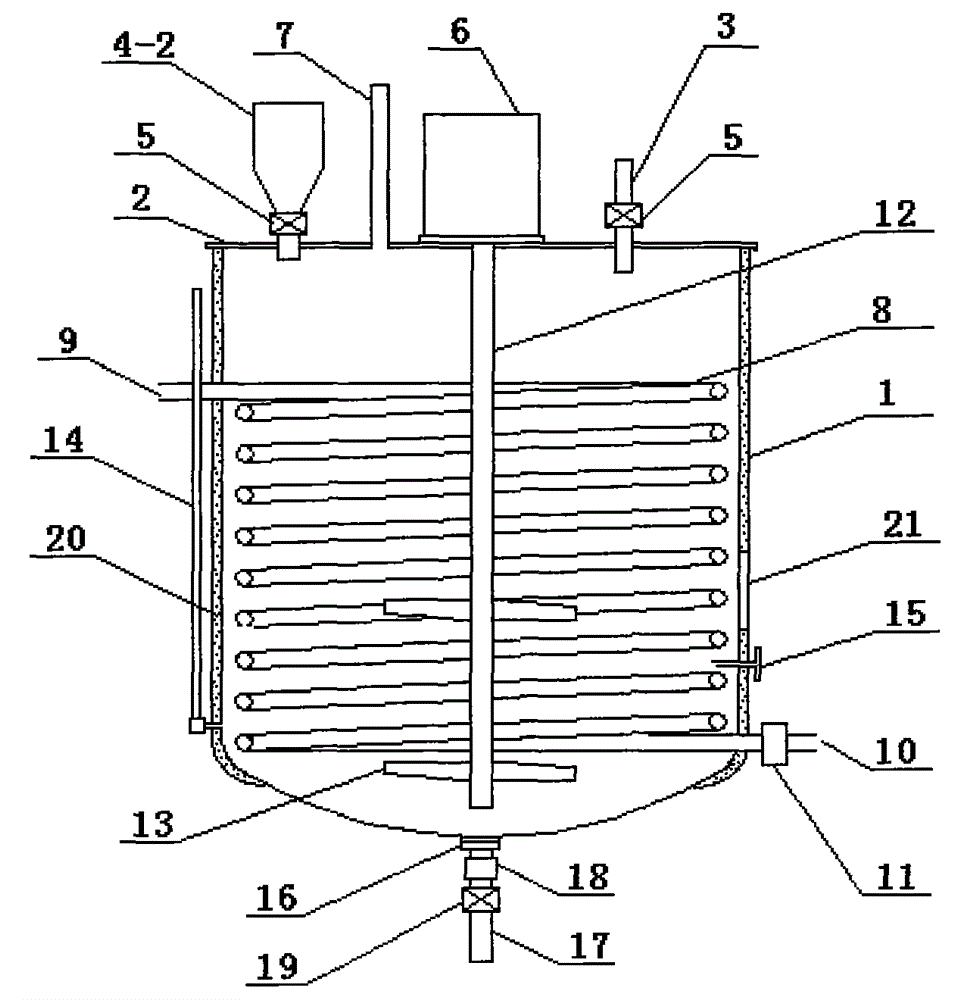

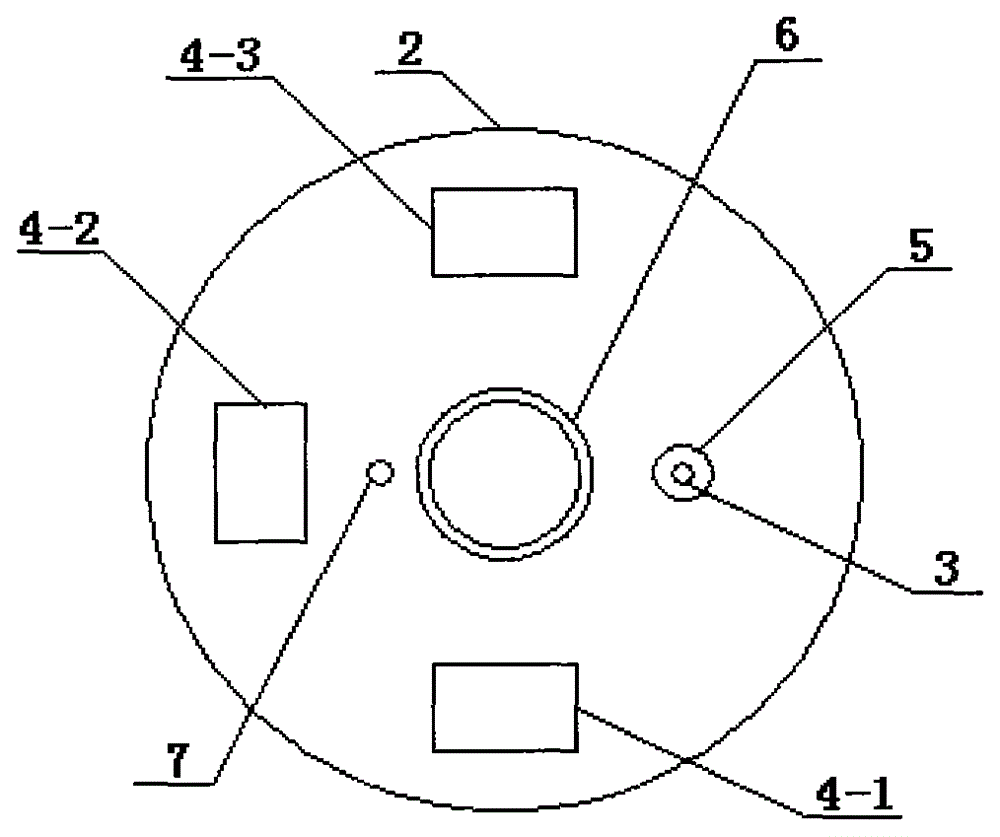

[0018] Specific embodiment: add the powder of raw materials to be chelated into the powder hoppers 4-1 to 4-3 respectively, connect the liquid material input pipe 3 to the hose and insert it under the liquid level in the liquid material container , start the quantitative addition program of raw materials, the liquid material is quantitatively sucked into the kettle by the feeding metering pump 5 through the hose, the steam switch valve is opened, and the steam enters the heating coil 8 from the heating inlet 10 through the heat controller 11 and then from the heating outlet 9 Return, heat up the kettle by circulation, at this time the frequency conversion motor 6 starts, drives the agitator to rotate and stir, and then controls the feeding metering pumps of the three powder hoppers 4-1 to 4-3 according to the order of adding raw materials for the chelation reaction 5. Then start, so that the three groups of powders are quantitatively added to the kettle from their respective po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com