Online digital automatic glue dispensing machine for thermal grease

A heat dissipation paste and automatic pointing technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of heat dissipation paste coating integrity, difficulty in ensuring thickness, low work efficiency, low efficiency, etc., and achieve the improvement point Glue efficiency, high glue supply efficiency, and the effect of ensuring product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

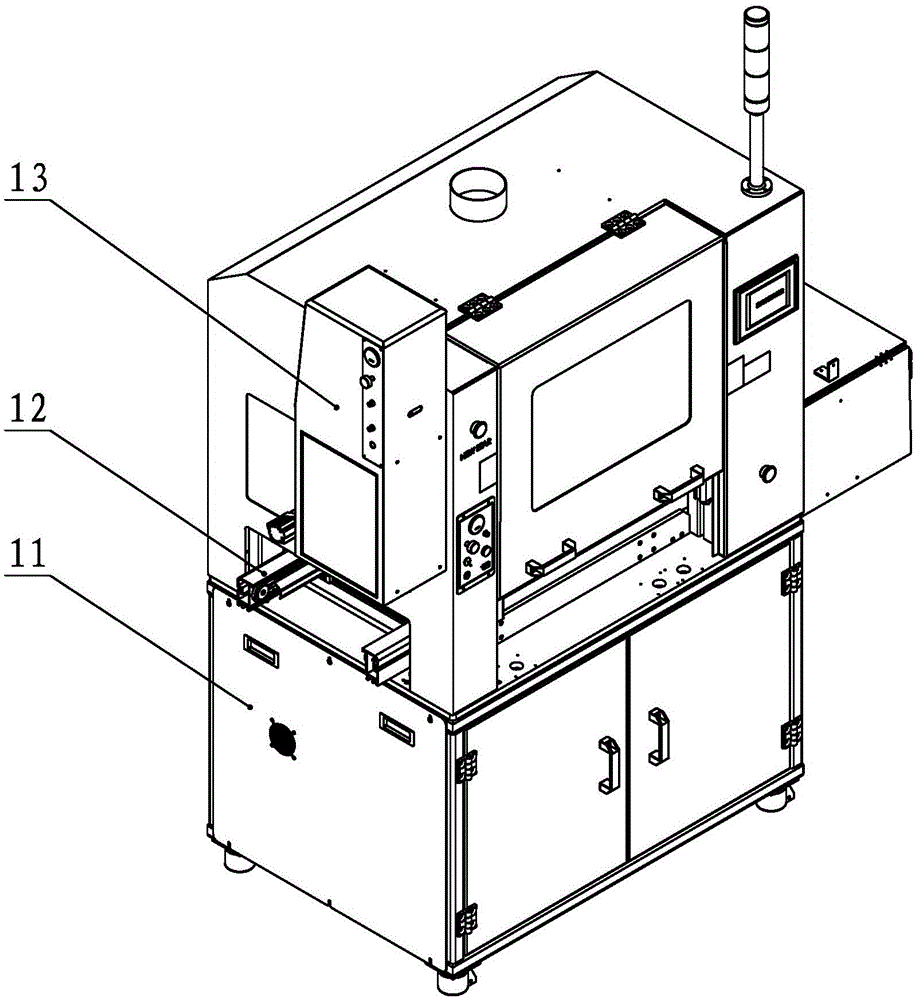

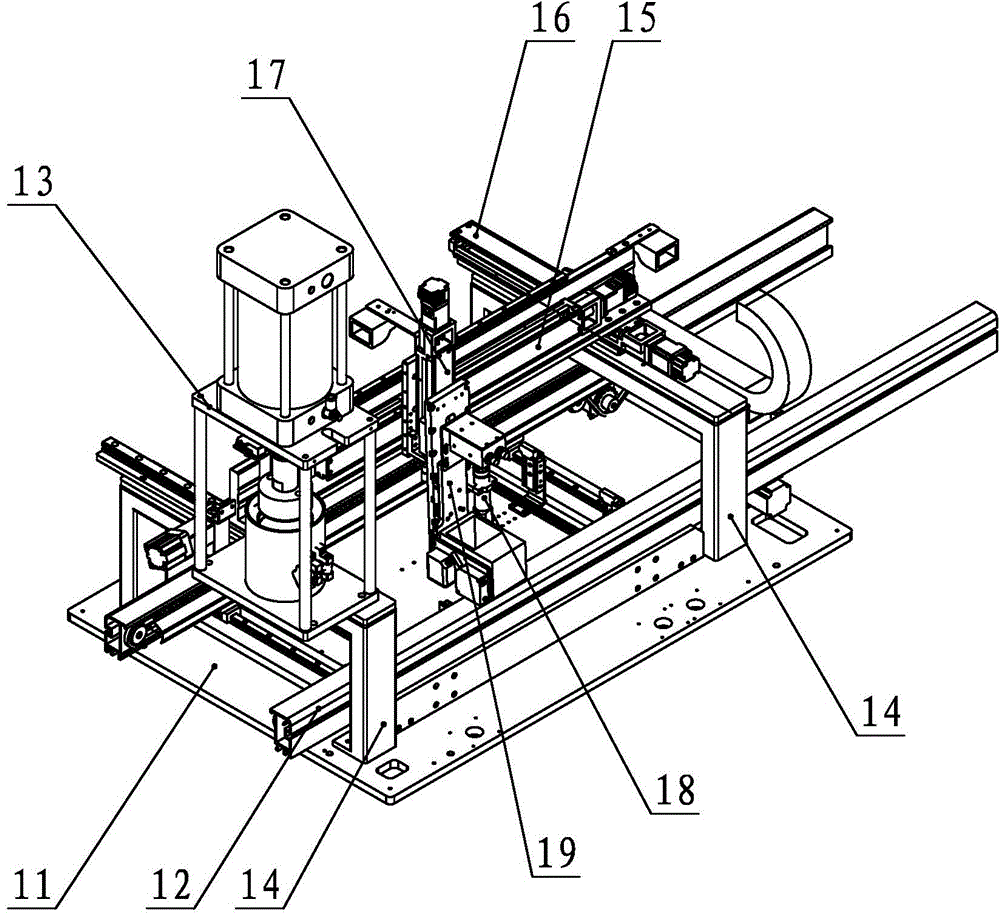

[0029] refer to Figures 1 to 4 , the on-line thermal paste digital automatic dispensing machine provided by the present invention includes a machine platform 11, which is provided with an online conveying mechanism 12 connecting the front and rear stations, and a dispensing valve 18 corresponding to the online conveying mechanism 12 and an online detection Agency 19;

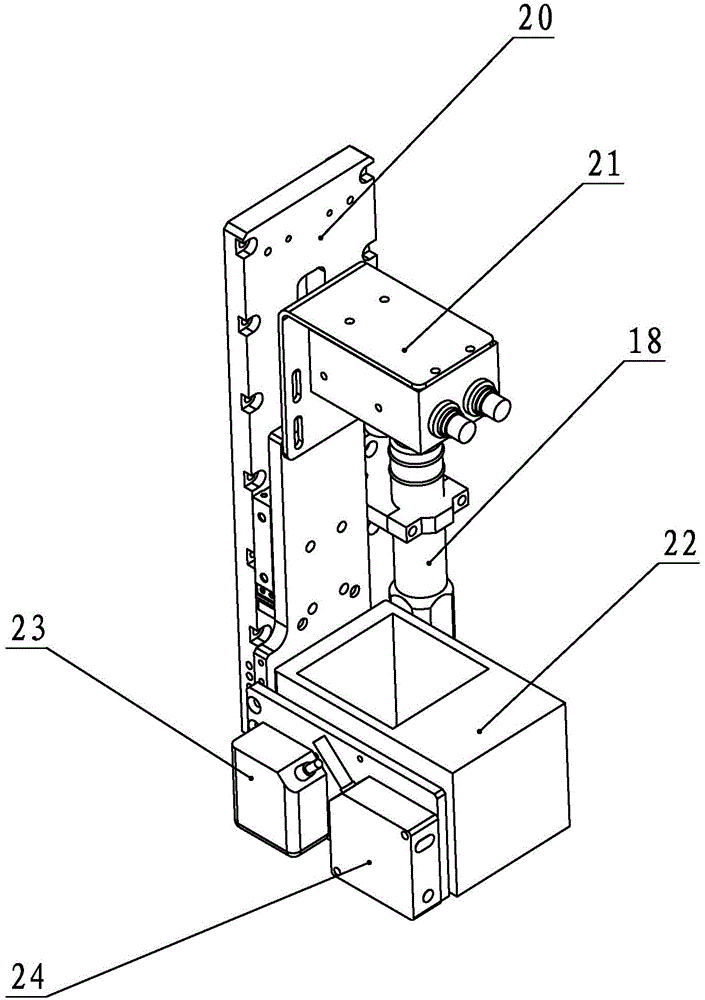

[0030] Both the inlet end and the outlet end of the online conveying mechanism 12 are provided with a gantry bracket 14, and the dispensing valve 18 and the online detection mechanism 19 are simultaneously installed on the gantry bracket 14 through the X-axis 15, the Y-axis 16, and the Z-axis 17. Above, the online detection mechanism 19 includes a CCD imaging device 21 , a two-dimensional code scanning device 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com