A detection device and detection method for oil pipe and sucker rod coupling

A sucker rod coupling and detection equipment technology, which is used in surveying, earthmoving, wellbore/well components, etc., can solve the problems of increased operating costs, serious wear and tear of parts, and unsatisfactory detection effect of couplings. Safe and reliable sealing performance, high degree of automation, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

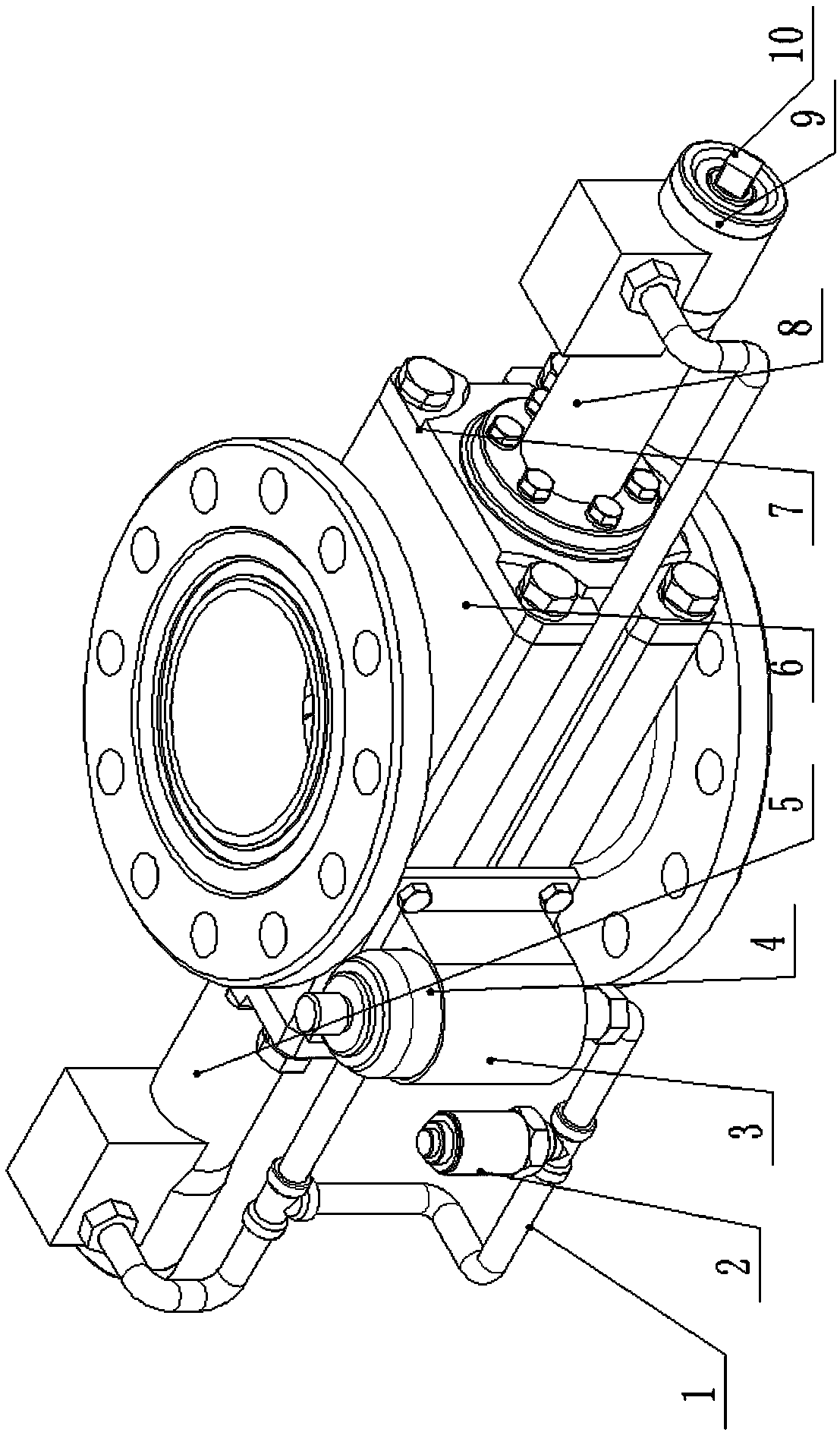

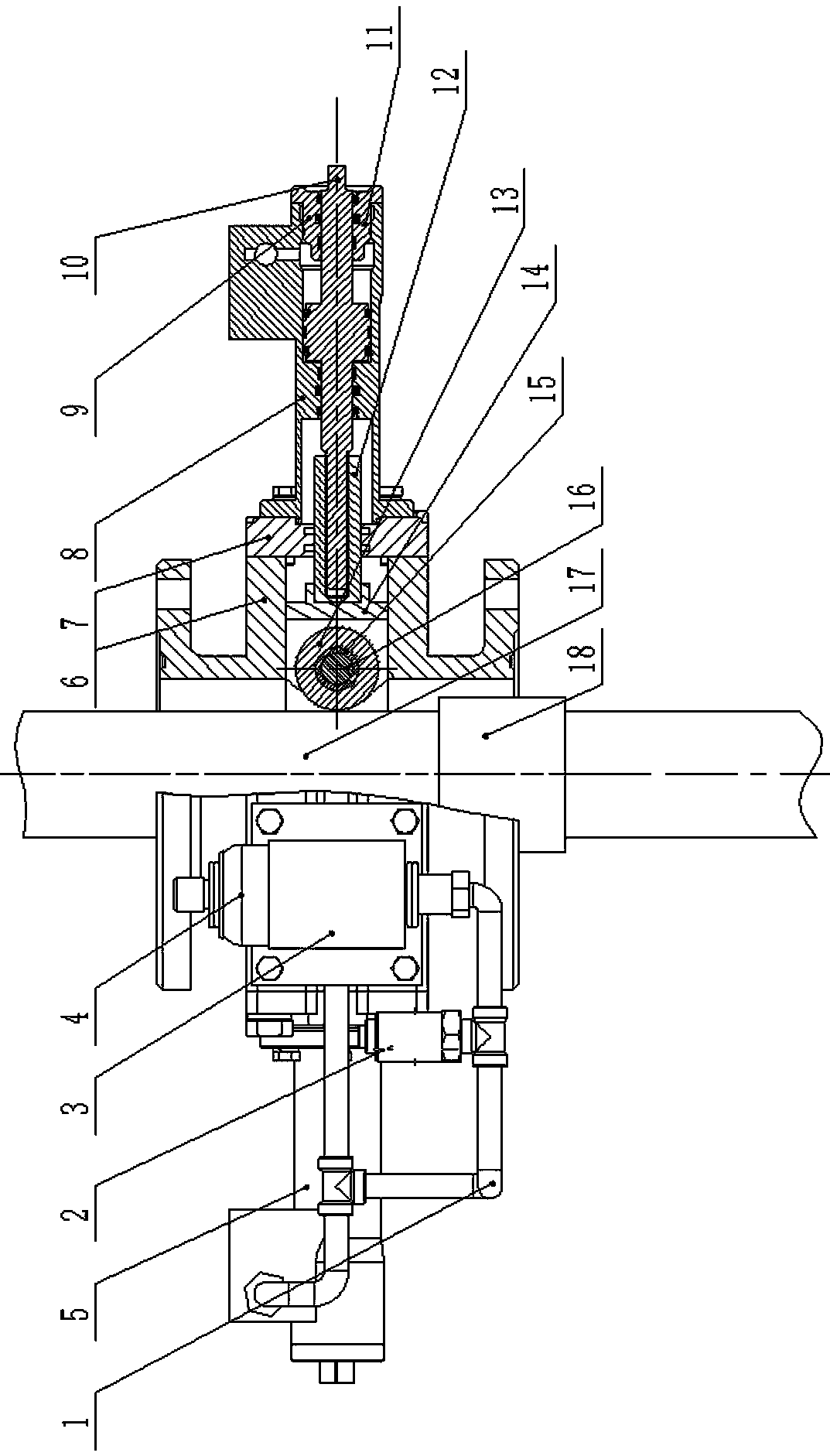

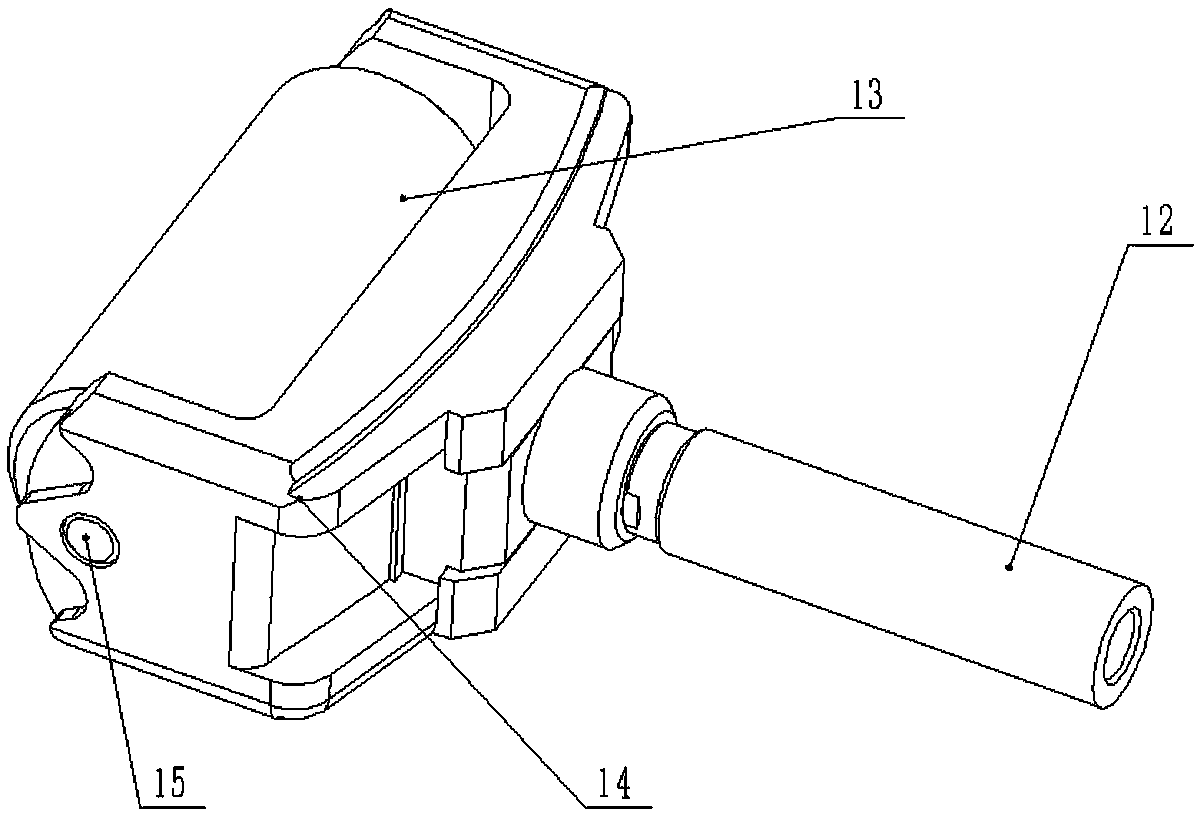

[0027] see Figure 1-4 , a new type of oil pipe coupling detection equipment, mainly composed of four parts: oil pipeline assembly 1, detection head assembly, oil pipe righting detection unit and signal measurement transmission unit. The detection head assembly is composed of detection shaft 12, detection roller 13 , detection shift fork 14, self-lubricating copper sleeve 15, oil pipe righting detection unit is composed of shell 6, shell end cover 7, detection arm 5 (8), detection arm end cover 7, adjusting and righting piston rod 10, the signal The measurement transmission unit is composed of an accumulator 4, an accumulator fixing frame 3, and a pressure sensor 2; the housing 6 is connected with the housing end cover 7 through bolts, and the housing end cover 7 is connected with the detection arm 5 (8 ) are fixed together by bolts, and the end c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com