Probe and scanning device for detecting turbine partition plate weld joint ultrasonic phased array

An ultrasonic phased array and scanning device technology, applied in the field of inspection, can solve the problems of inability to guarantee the safety of the weld, easy to miss inspection, low efficiency, etc., and achieve the effect of compact structure, no blind area, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in conjunction with the following examples.

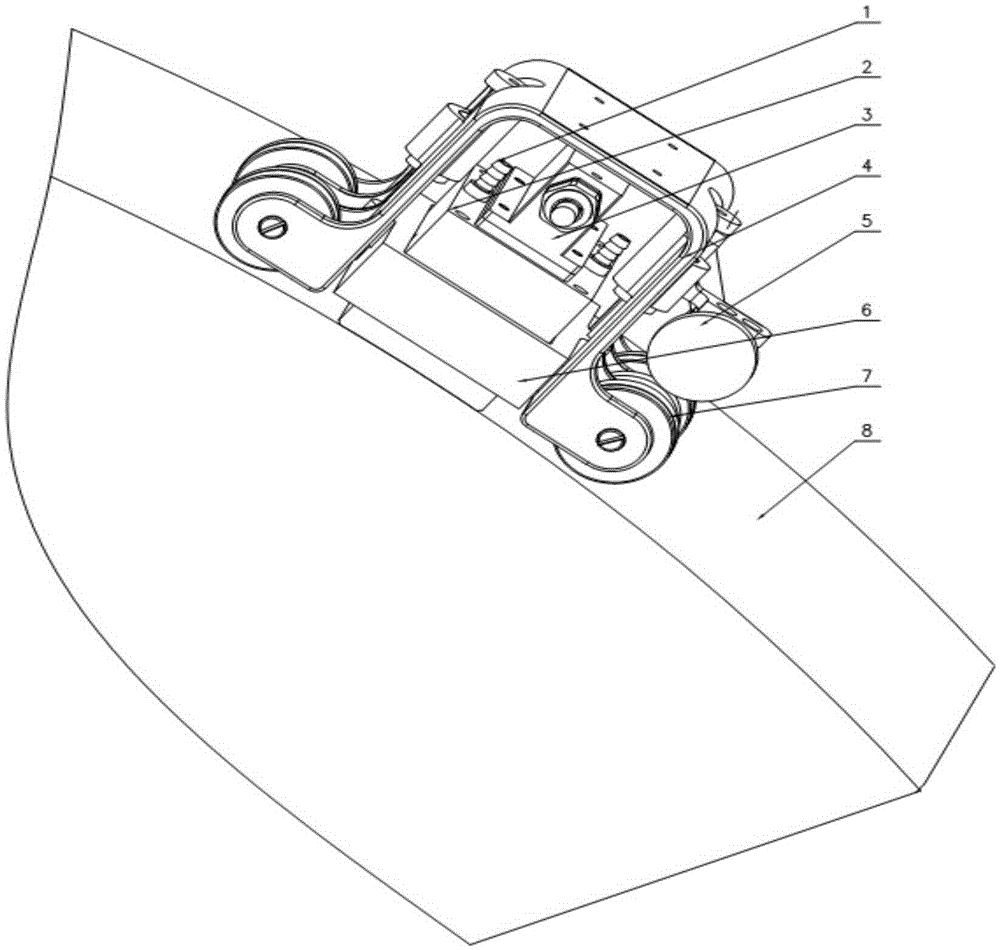

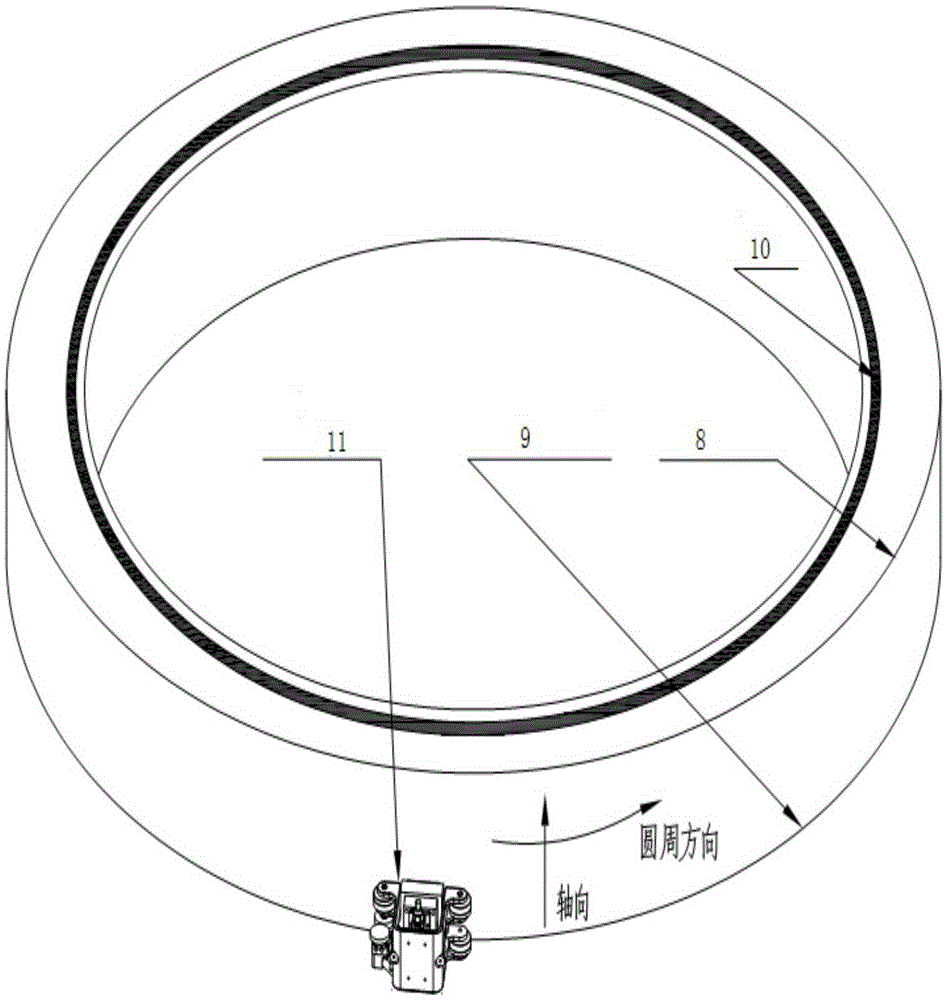

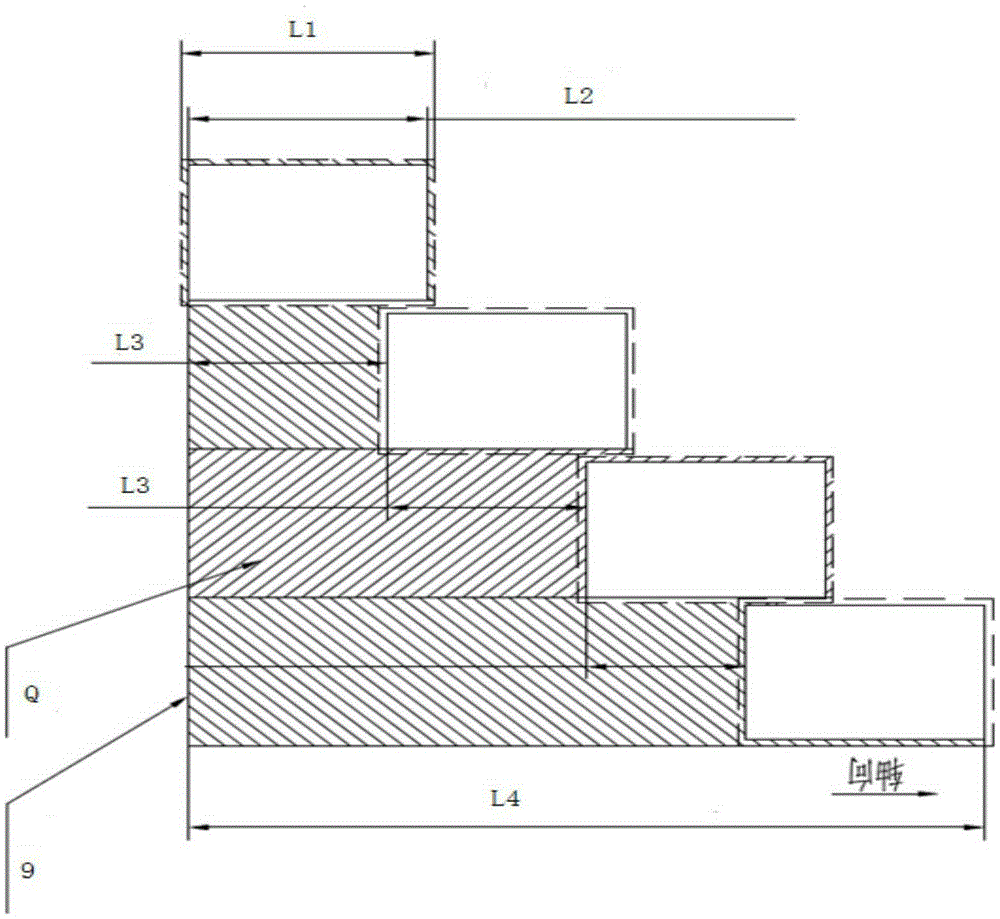

[0021] Such as figure 1 As shown, a probe and scanning device for ultrasonic phased array detection of steam turbine diaphragm welds, including water coupling electric watering can, wedge 2, ultrasonic phased array control probe 3, trolley 4, encoder 5 and wedge The clamping frame 6; the function of the water coupling electric watering can is to spray water to ensure the good coupling between the ultrasonic phased array probe 3 and the measured workpiece 8; In the frame 6; the ultrasonic phase array control probe 3 is installed on the wedge 2; the water coupling electric watering can water inlet nozzle 1 of the water coupling electric watering can for water injection is located on the wedge 2; the encoder 5 is installed on the wedge 2 On the frame of the trolley 4, it is used to record the scanning trajectory; the trolley 4 is equipped with a wheel 7 that is in contact with the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com