All-fiber quarter wave plate packaging method

A packaging method and all-fiber technology, applied in the direction of voltage/current isolation, etc., to achieve good sealing, simple structure, and long-term use stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

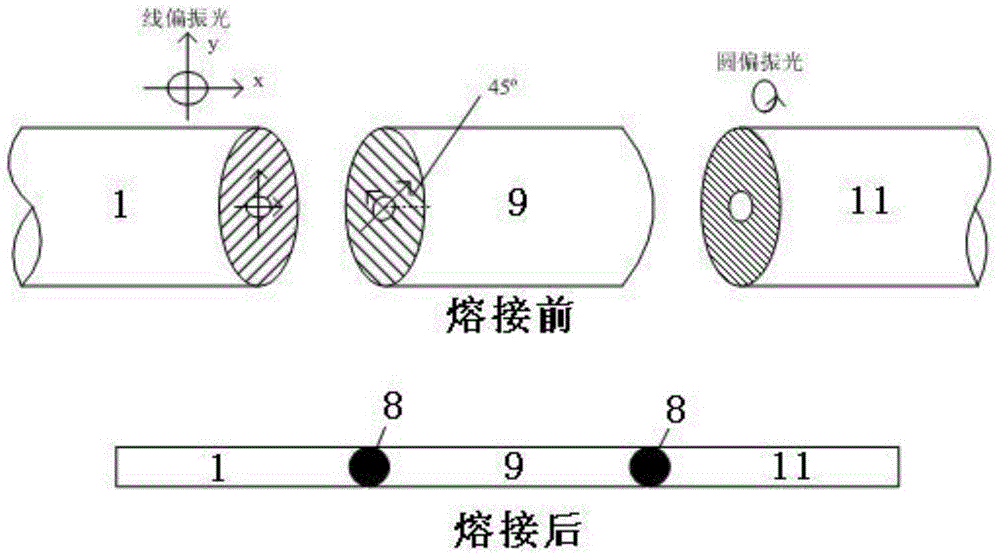

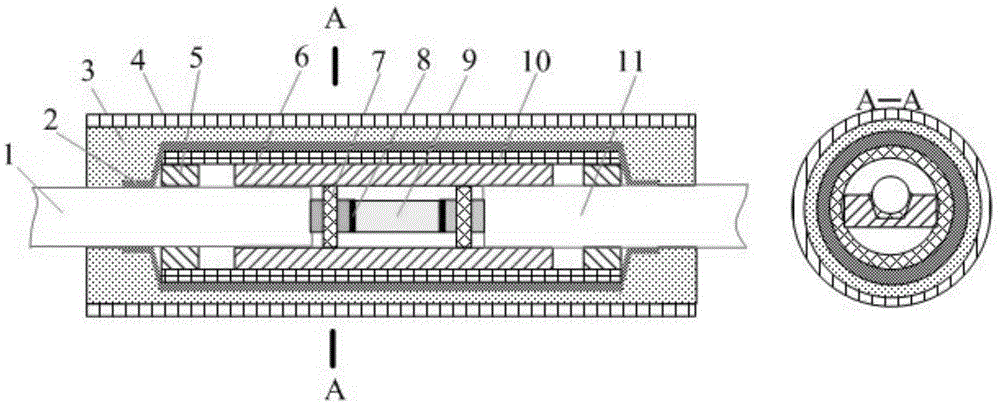

[0031] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] like figure 2 Shown is a schematic diagram of the packaging structure of the fiber end reflector of the present invention. The packaging process of the all-fiber quarter-wave plate of the present invention mainly includes the following steps:

[0033] (1) Place the all-fiber quarter-wave plate horizontally in the middle of the slotted quartz plate, and reserve the same distance between the left and right ends of the quartz plate;

[0034] In this embodiment, the shape of the groove on the quartz plate is one of the following two shapes: trapezoidal or U-shaped.

[0035] (2) At a distance of 1 to 1.5 mm from the left and right ends of the full-fiber quarter-wave plate, apply the first fiber-optic fixing glue, heat and cure, and then let it stand; glue can be dispensed multiple times, and the gap can be filled with heating. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com