Overlapped copper-acid storage battery

A battery, cupric acid technology, applied in the direction of half-lead battery, etc., can solve the problems of losing supporting active material and build-up current, the battery cannot be charged, and the number of cycles is limited, so as to achieve the effect of long service life, extended service life and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

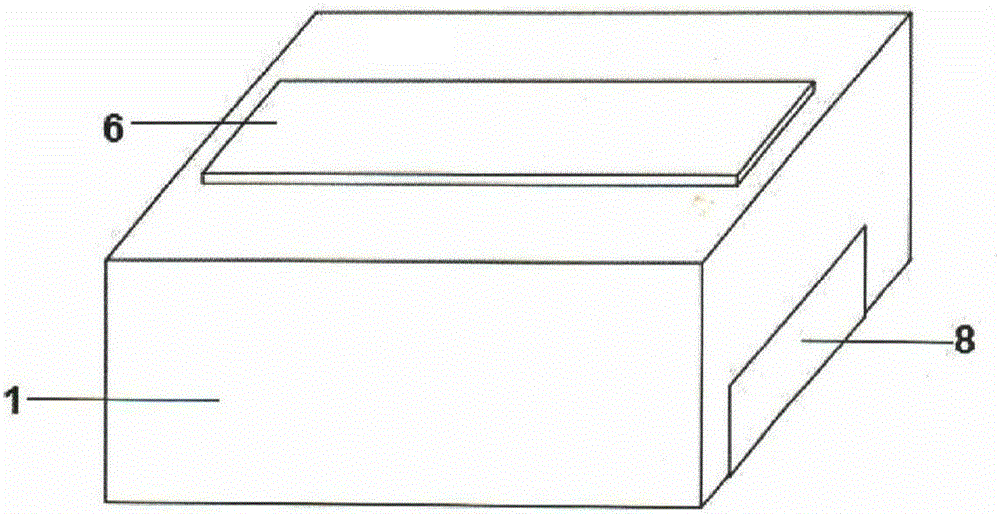

[0048] Make a single such as figure 1 , Figure 5 The shown 1.4V250AH copper acid battery contains a positive plate, a negative plate and a glass fiber separator.

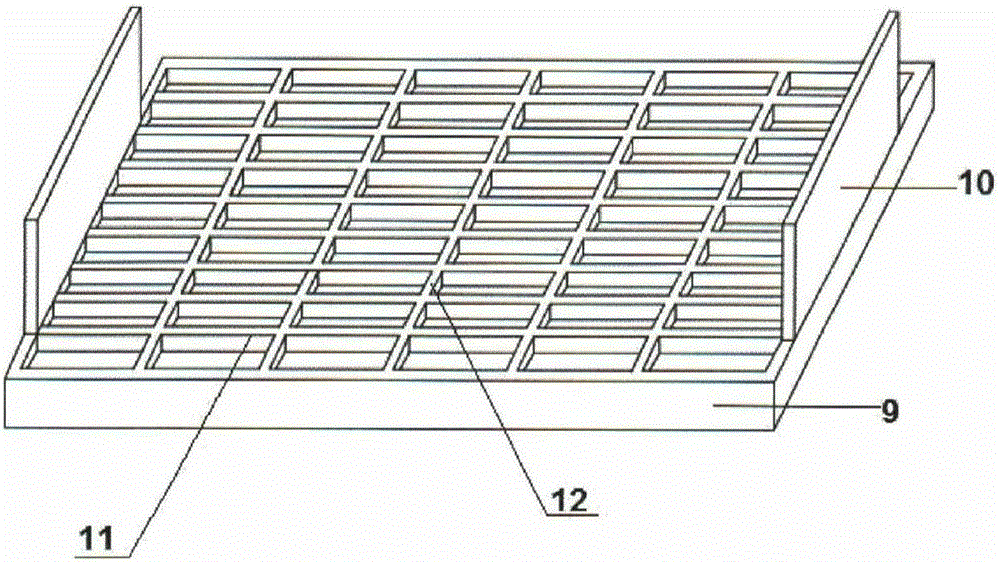

[0049] by figure 2 The positive plate is used as a model, and the production is as follows Figure 7 The positive plate shown. The size of the positive plate frame is 53.2 cm long, 31.5 cm wide, and 0.6 cm thick, with 31 holes in the horizontal direction and 31 holes in the vertical direction, and the active material is lead dioxide. There are three protruding lead pile heads outside the frame, which are welded on as figure 2 The riser 10 shown in is connected to the positive electrode conductive copper plate 6, and the number of risers is 2.

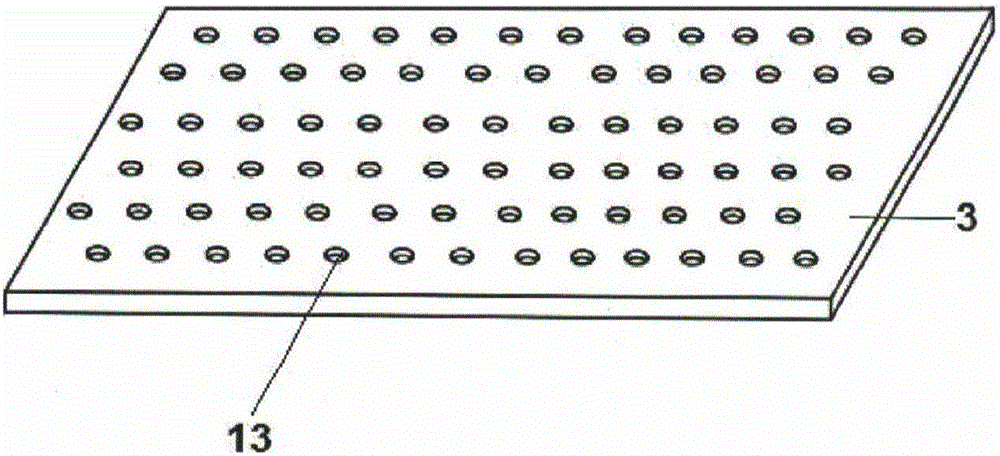

[0050] Negative plate with image 3 The sample plate is adjusted accordingly, and the size of the shell is designed according to the total volume of the positive and negative plates plus the electrolyte and the reserved space. The carrier fluid of the negative plate...

Embodiment 2

[0053] Make a single such as figure 1 , Figure 5 The shown 1.4V250AH copper acid battery contains a positive plate, a negative plate and a glass fiber separator.

[0054] by figure 2 The positive plate is used as a model, and the production is as follows Figure 7 The positive plate shown. The size of the positive plate frame is 53.2 cm long, 31.5 cm wide, and 0.6 cm thick, with 31 holes in the horizontal direction and 31 holes in the vertical direction, and the active material is lead dioxide. There are three protruding lead pile heads outside the frame, which are welded on as figure 2 The riser 10 shown in is connected to the conductive copper plate 6, and the number of risers is 2.

[0055] Negative plate with image 3 The sample plate is adjusted accordingly, and the size of the shell is designed according to the total volume of the positive and polar plates plus the electrolyte and the reserved space. The carrier fluid of the negative plate is copper material, a...

Embodiment 3

[0058] Make a single such as figure 1 , Figure 5 The shown 1.4V250AH copper acid battery contains a positive plate, a negative plate and a glass fiber separator.

[0059] by figure 2 The positive plate is used as a model, and the production is as follows Figure 7 The positive plate shown. The size of the positive plate frame is 53.2 cm long, 31.5 cm wide, and 0.6 cm thick, with 31 holes in the horizontal direction and 31 holes in the vertical direction, and the active material is lead dioxide. There are three protruding lead pile heads outside the frame, which are welded on as figure 2 The riser 10 shown in is connected to the positive electrode conductive copper plate 6, and the number of risers is 2.

[0060] Negative plate with image 3 The sample plate is adjusted accordingly, and the size of the shell is designed according to the total volume of the positive and polar plates plus the electrolyte and the reserved space. The carrier fluid of the negative plate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com