Combined type multi-layer composite electrical connection structure for inversion device

A technology of electrical connection and converter device, applied in the direction of connection, fixed connection, electrical components, etc., can solve the problems of low reliability, large space, high cost, improve system reliability, reduce peak voltage, and reduce overall cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

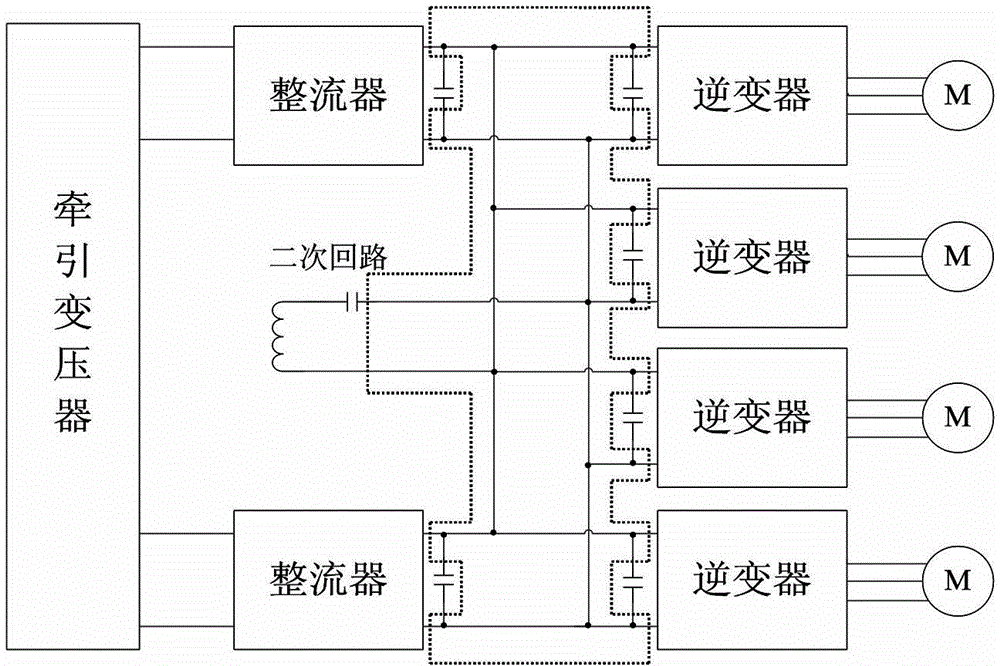

[0027] Such as figure 1 As shown, it is a specific application example of the converter device, in which the converter device adopts a symmetrical layout structure in design, with a rectifier and two inverters as a group, and each group is connected to the secondary circuit (by the inductor and a resonant circuit composed of capacitors). The circuit between the rectifier and the inverter is often designed as an intermediate DC circuit, and there is a complex circuit connection between the intermediate DC circuit and the secondary circuit, with many connection points and complex types, as shown in the circuit part in the dotted line box in the figure, namely For the application object of the present invention. In this dotted line box, the circuit as a whole presents a symmetrical structure.

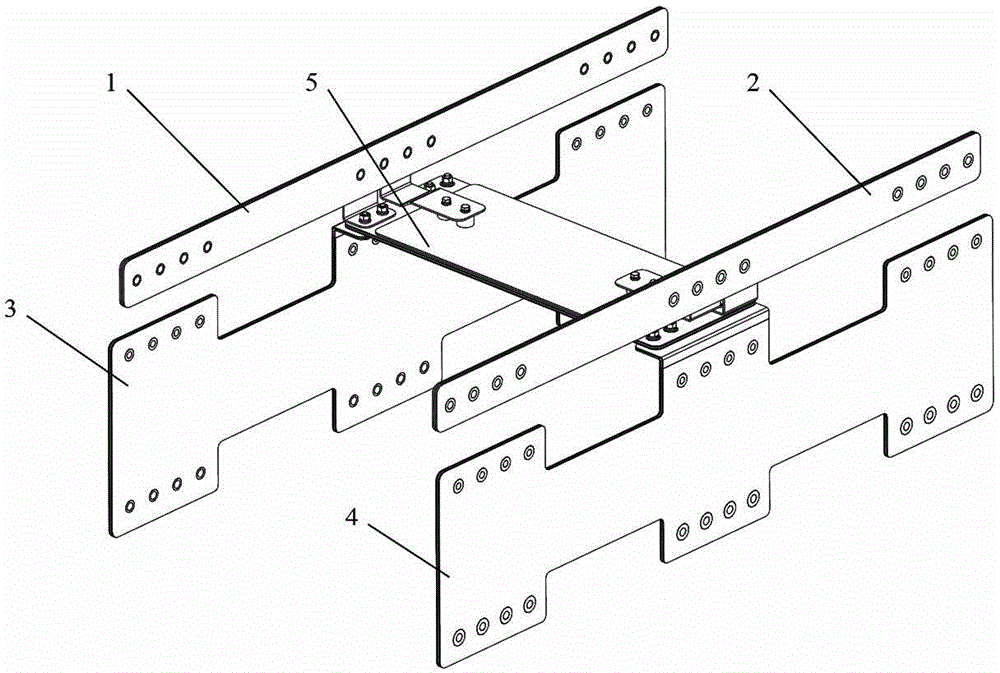

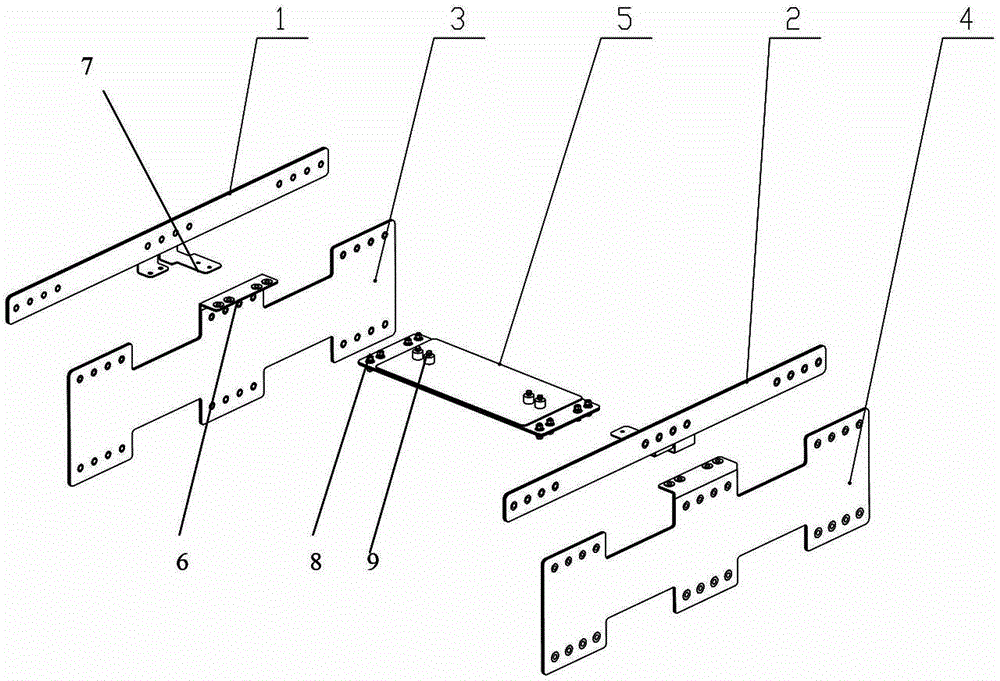

[0028] Such as figure 2 with image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com