Method for setting elastic thread in a ligation device and elastic thread ligation device

A technology of elastic thread and ligation device, which is applied in the field of medical equipment, can solve the problems of long operation time, low work efficiency, waste, etc., and achieve the effect of avoiding the increase of operation cost, improving work efficiency and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

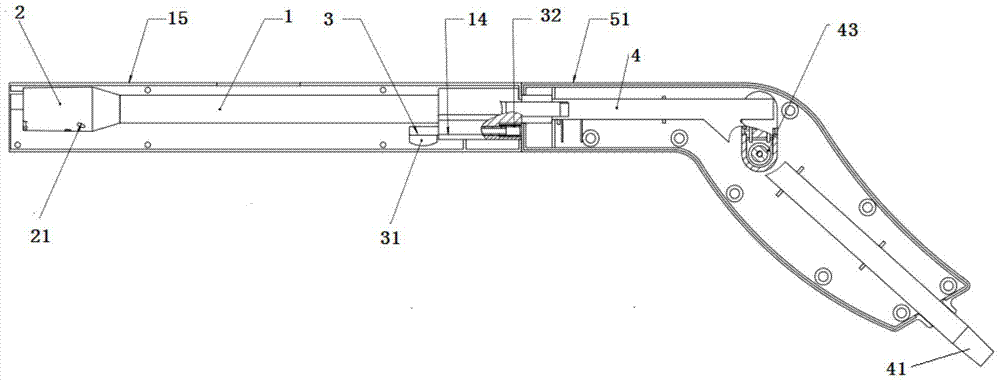

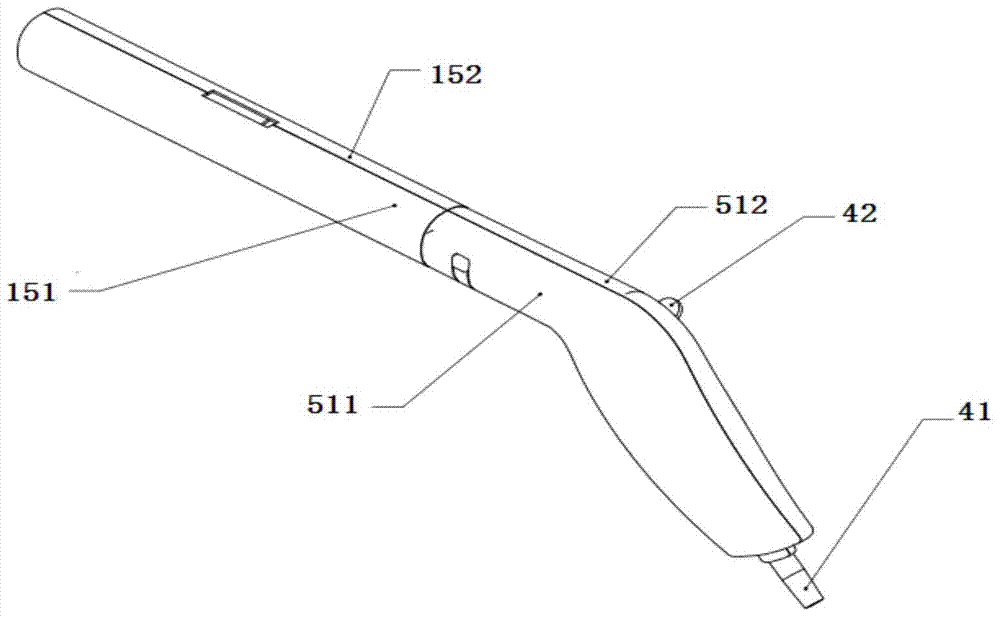

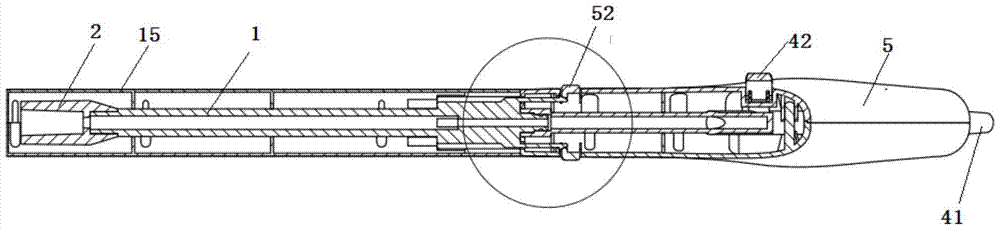

[0089] Such as Figure 1-7 As shown, an elastic thread ligation device in this embodiment includes a gun head, a gun body 5 and four elastic threads, and the gun head and the gun body 5 are detachably connected.

[0090] The gun head is a hollow tubular structure, and the gun head includes a gun head main body 1 and a gun head fixing sleeve 2, and the gun head fixing sleeve 2 is sleeved on the front end of the gun head main body 1; The inner wall of the pipe 2 is provided with a groove 2, and the front end of the gun head main body 1 is provided with a protrusion 2, and the groove 2 corresponds to the protrusion 2, so as to realize the fixed socket of the gun head main body 1 and the gun head fixed sleeve 2 .

[0091] Four threading holes 21 are provided on the pipe wall at the front end of the gun head. The first hole 211 at the front end of the threading hole 21 is arranged on the nozzle of the fixed sleeve 2 of the gun head, and the second hole 212 at the rear end of the t...

Embodiment 2

[0130] The difference between this embodiment and Embodiment 1 is that no elastic thread fixing card 11 is provided under the gun head body 1 of the elastic thread ligation device, and the elastic thread fixing sleeve uses an orifice that can be clamped in the corresponding threading hole Second, the elastic thread fixing beads or other elastic thread fixing parts are replaced to fix the tail end of the elastic thread.

[0131] Correspondingly, the elastic thread fixing card cover 14 provided outside the elastic thread fixing card 11 can also be omitted.

[0132] During the operation, directly hold the elastic thread fixing beads or other elastic thread fixing components, and at the same time tighten the elastic thread according to the method described in Example 1 to complete the entire operation process.

[0133] The legend of this embodiment is similar to that of Embodiment 1 and is omitted here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com