Flue-dust processing equipment

A technology for processing equipment and smoke and dust, applied in the field of air purification, can solve the problems of high dust removal efficiency, large workload and low cost, and achieve the effects of improving efficiency, increasing contact area, and promoting water level balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

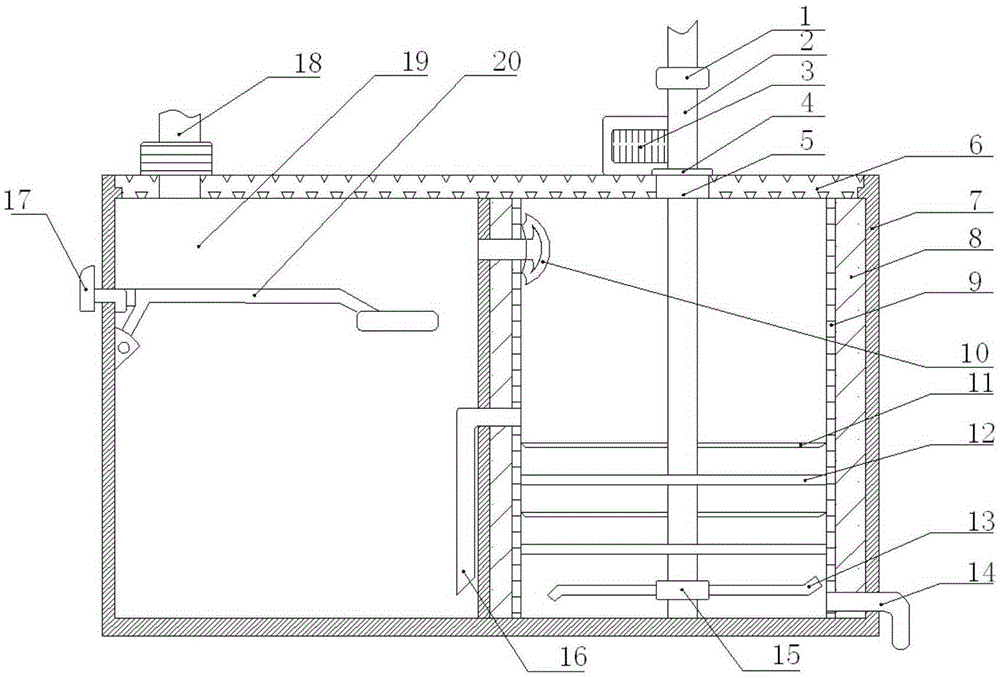

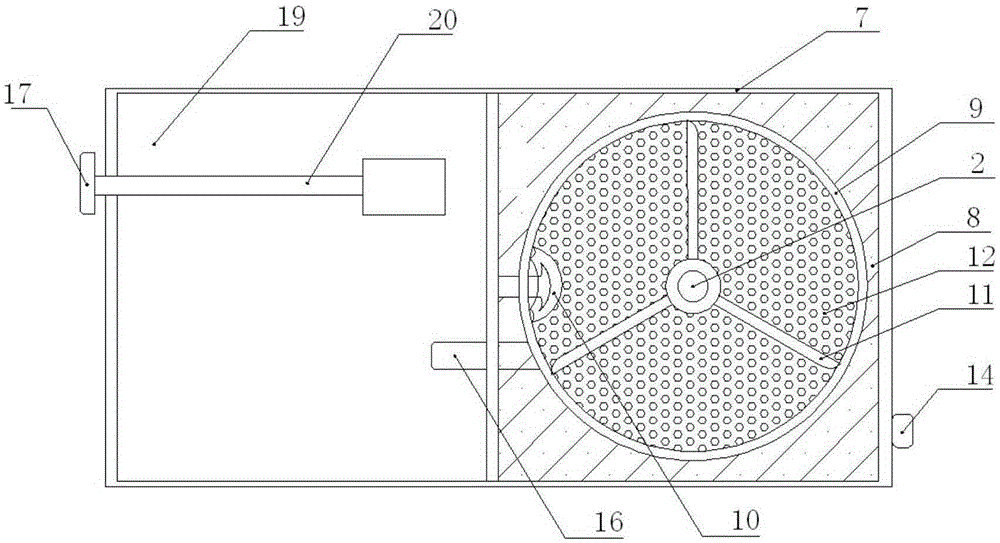

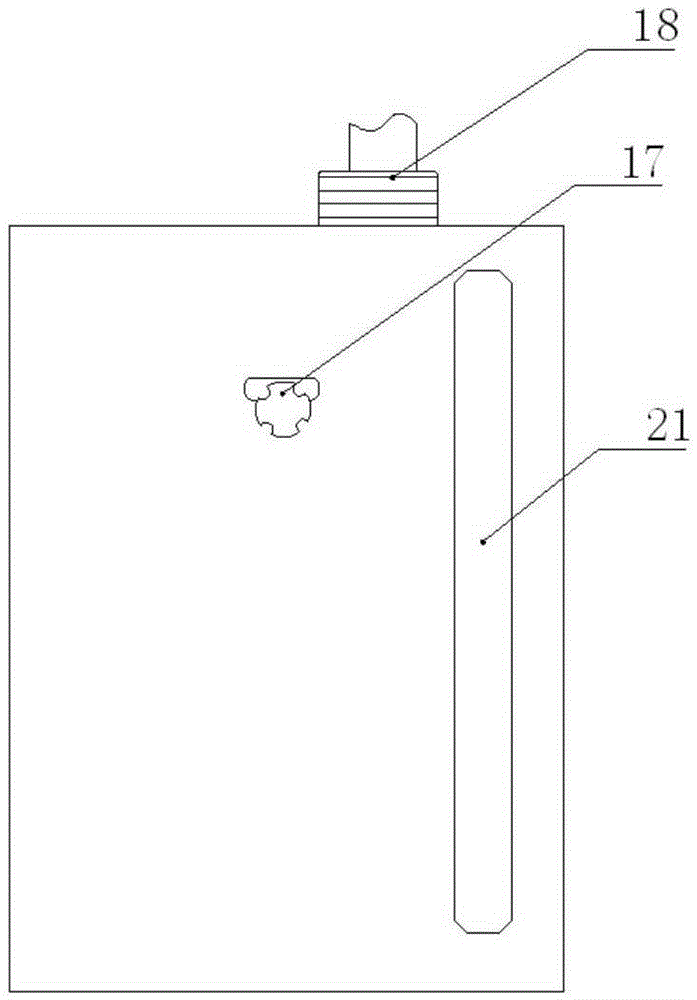

[0027] Such as figure 1 As shown, the present invention relates to a kind of soot treatment equipment, including a box body and a box cover 6, a vertical partition is arranged in the box body, and the box body is divided into a stirring box body 7 and a clean water box body 19 , a mixing bucket 9 is embedded inside the mixing box. The box cover is installed on the mixing box and the water purification box, so that the whole smoke treatment device is a closed rectangular box.

[0028] A hollow rotating standpipe 2 is coaxially arranged in the mixing bucket, the upper end of the rotating standpipe is installed on the box cover through a waterproof bearing 5 and extends upward to the top of the box cover, and the lower end of the rotating stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com