Device and method for recovering gas of nitrogen oxides in production process of nitro-cotton

A production process and recovery device technology, applied in chemical instruments and methods, separation methods, nitric acid, etc., can solve the problems of low concentration of dilute nitric acid, large amount of dilute nitric acid, single nitric acid user, etc., to improve economic benefits and meet sales needs , to ensure the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

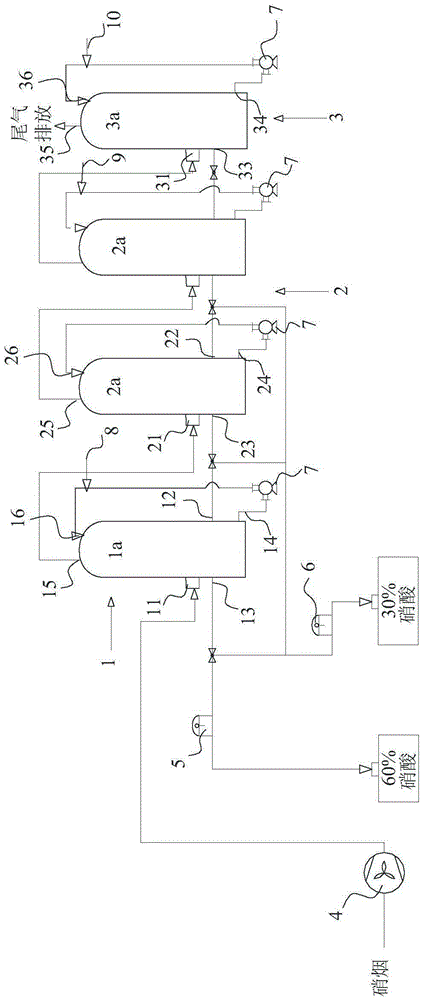

[0030] like figure 1 as shown in figure 1 The structure diagram of the gunpowder smoke recovery device in the shown nitrocellulose production process of the present invention, the gunpowder smoke recovery device in the nitrocellulose production process includes: the first absorption unit 1, the second absorption unit 2, the third absorption unit 3, exhaust fan 4 and The first hydrometer 5, the second hydrometer 6; the first absorption unit 1 includes the absorption tower 1a that the absorbent is water; the second absorption unit 2 includes 4 series-connected absorption towers 2a that the absorbent is water, It is arranged at the post station of the first absorption unit 1 and is connected in series with it; the third absorption unit 3 includes up to two absorption towers 3a whose absorbent is a mixed solution of urea and hydrogen peroxide, and is arranged at the post station of the second absorption unit 2 and connected with it. in series.

[0031] The bottom of the water wash...

Embodiment 2

[0048] In the nitrocellulose production process provided by the present invention, the gunpowder smoke recovery device is as embodiment 1, and the recovery method comprises the following steps:

[0049] (1) Close and open the valve on the connecting pipeline between the first absorption unit 1 and the second absorption unit 2 absorption tower, and the upper water inlet 9 of the last absorption tower circulation pump 7 of the second absorption unit 2 flows into the absorption tower of the second absorption unit 2 Add water, the water flows back to the first absorption unit 1, after the liquid level of the washing absorption tower 1a reaches 10-30%, close the valve on the connecting pipeline of the first absorption unit 1 and the second absorption unit 2 absorption tower, start the circulation pump 7, Water circulates from top to bottom in the absorption tower;

[0050] (2) Treat that the liquid level of each absorption tower of the second absorption unit 2 reaches 10-30%, start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com