Organic fertilizer granulating device

An organic fertilizer and equipment technology, applied in the field of organic fertilizer granulation equipment, can solve the problems of complex structure and process, reduce production efficiency, increase production cost of enterprises, etc., and achieve the effect of adjustable granulation size, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

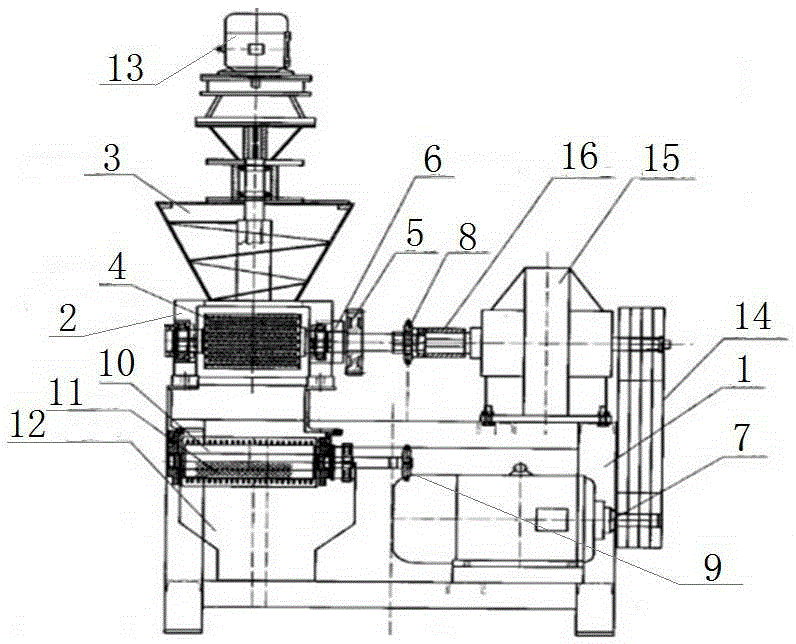

[0012] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment comprises body 1, and extrusion box 2 is installed on body 1, and screw feeder 3 is arranged on the top of extrusion box 2, is provided with two extrusion rolls 4 side by side in extrusion box 2, two extrusion rolls 4 is meshed and connected by the gear 5, and the two ends of the two extrusion rolls 4 are installed on the roll adjustment sleeve 6, and one of the extrusion rolls 4 is connected with the first motor 7, and the end of the extrusion roll 4 connected with the first motor 7 is installed Drive sprocket 8 is arranged, and drive sprocket 8 is connected with passive sprocket 9, and passive sprocket 9 is installed on the granulation roll 10, and granulation sieve 11 is provided with granulation roll 10 below, and granulation sieve 11 below is provided with outlet. Hopper12. The screw feeder 3 is connected with a second motor 13 . The first motor 7 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com