Modified PVA polyvinyl alcohol polymer surfactant for displacement of reservoir oil

A surfactant and polyvinyl alcohol technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor oil displacement efficiency and complex composition of oil displacement systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment P

[0014] Example PVA and oleic acid

[0015] Heat the PVA aqueous solution with a mass fraction of 10% to 90°C, use hydrochloric acid to adjust the pH to 2, then add oleic acid, the amount of PVA and oleic acid is 20:1 (mass ratio), and react for 2 to 4 hours. After the reaction, the performance test of the obtained product was carried out.

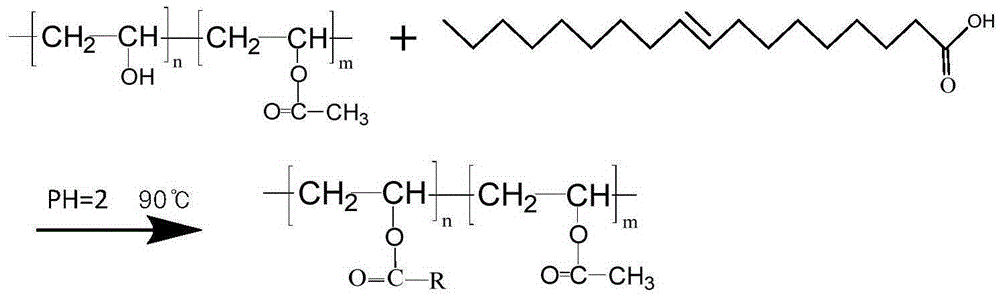

[0016] Reaction equation:

[0017]

[0018] Among them, R is -C 17 h 34 The structure is the same as that of the long chain of oleic acid, m and n are subscripts, representing the number of repeating units, among which 100<m<120, 1580<n<1600. The model of polyvinyl alcohol used in this example is PVA-1788, that is, the degree of polymerization is 1700, and the degree of alcoholysis is 88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com