Spinning system composed of multiple short spinning frames connected in series

A spinning frame and spinning technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of high cost of transformation, small space, high cost of technical transformation or inconvenience, etc., to avoid a large number of The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

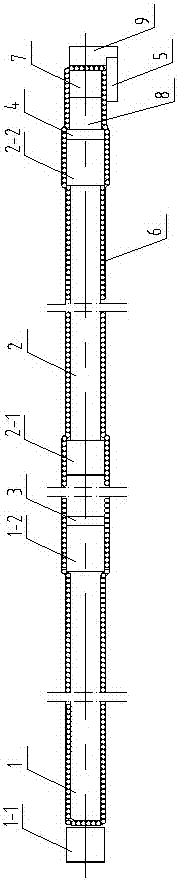

[0013] Such as figure 1 As shown, the present invention is provided with at least two groups of short spinning frames 1 and 2 arranged in series with each other, and each group of short spinning frames 1, 2 is provided with a transmission and end-breaking cotton suction system respectively.

[0014] The short spinning frame 1 is provided with a front 1-1 and a rear 1-2, and the short spinning frame 2 is also provided with a front 2-1 and a rear 2-2.

[0015] The rear 1-2 of the short spinning frame 1 and the front 2-1 of the short spinning frame 2 are arranged opposite, and the suction is arranged between the rear 1-2 of the short spinning frame 1 and the front 2-1 of the short spinning frame 2. Cotton bellows 3, a cotton suction bellows 4 and a full yarn collecting device 5 are arranged behind the rear 2-2 of the short spinning frame 2.

[0016] A set of ring-shaped convex disc conveying guide rails 6 are arranged outside all the short spinning frames 1, 2 connected in series.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com