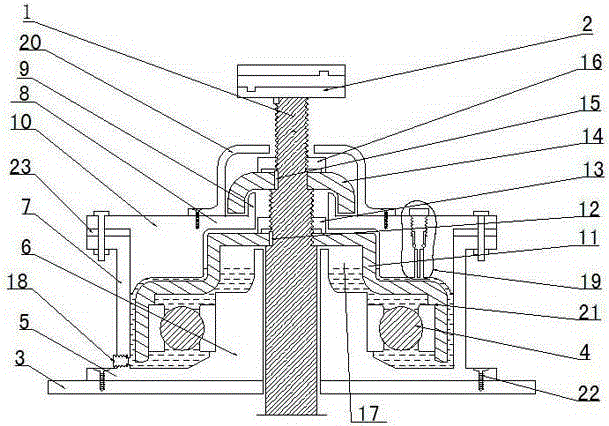

Normal-temperature self-gas-sealing device for bearing

A sealing device and hermetic sealing technology, which is applied in the field of bearing sealing, can solve problems such as heat generated by sliding friction, waste of inert gas, and increased equipment investment, so as to reduce maintenance costs and raw material consumption, reduce bearing temperature rise and power loss, The effect of improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

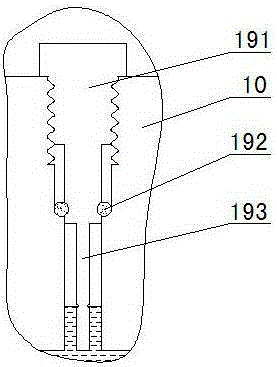

Method used

Image

Examples

Embodiment 1

[0034] For example, the application number CN20141034266.4 discloses a high-shear grinding reactor. High-speed operation is a key parameter. The sealing method adopted is to continuously feed inert gas or reaction gas. This method is used as a laboratory reaction It is acceptable to waste a little inert gas or non-toxic reaction raw material gas (such as carbon dioxide), but it is obviously not cost-effective for industrial production. Applying the present invention to a "high-shear grinding reactor" is very suitable for reactions in which the internal and external pressures of the reactor are all within the range of normal pressure. The specific operation process is as follows:

[0035] 1. Installation and docking of equipment

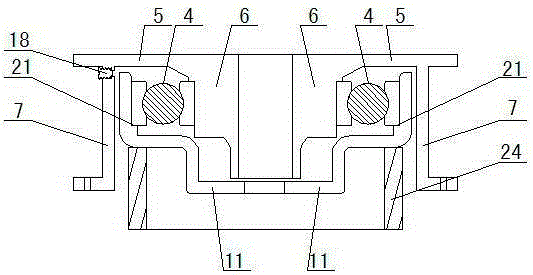

[0036] 1. If image 3 , let the opening of the shaft lip A11 face up, and place it on the ring bracket 24, first assemble the bearing 4 on the shaft lip A11, and then install the inner lip 6 of the bottom plate on the inner sleeve of the bearing 4; ...

Embodiment 2

[0050] Spherical nano-calcium carbonate has many uses, and its production method is mostly prepared by reacting slaked lime (calcium hydroxide) and carbon dioxide with water as the solvent.

[0051] The equipment docking of this embodiment is the same as that of Embodiment 1, and the reaction operation is as follows:

[0052] 1. If Figure 4 , connecting the air inlet 30 to a carbon dioxide gas source whose outlet pressure is normal pressure.

[0053] 2. Start the stirring device. According to the reaction needs, open the valve at the cooling water inlet 26, add metered powdery calcium hydroxide through the solid feed port 29, and open the valve at the air inlet 30 to add carbon dioxide.

[0054] 3. Check the pH value of the reaction solution through the solid feeding port 29, and close the valve of the air inlet 30 when the pH value is 5.

[0055] 4. Open the discharge port 33, discharge the material, and continue post-processing the semi-finished nano-calcium carbonate emu...

Embodiment 3

[0058] The device docking of this embodiment, such as Figure 5 , except that the bottom plate 5 of the present invention 25 and the reactor top cover 3 are directly fixed together by bolts, then the reactor top cover 3 is fixed to the reactor by bolts, and the lower end of the stirring shaft 1 is installed with a stirring paddle 38 Except, all the other are with embodiment 1. In this embodiment, the reactor is wrapped with a heating jacket 37 filled with heating oil. The heating jacket 37 is provided with an electric heating tube 47 and an electric heating jacket temperature probe 40. One end of the heating jacket 37 is provided with a heating oil feeding port 39, and the other end A heating jacket vent pipe 44 is provided, and an insulating layer 45 is provided outside the heating jacket 37; a cooling pipe inlet 41, a reaction liquid temperature probe 42 and a cooling pipe outlet 43 are arranged in the reactor, and an input gas port 35 is provided at the upper end of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com