Rolled steel macrostructure hot acid etching device

A technology of low-magnification structure and thermal acid etching, which is applied in the directions of measuring devices, analysis materials, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of poor safety, lower thermal efficiency, consumption of absorption liquid, etc., to achieve safe and reliable use, reduce Production cost, the effect of ensuring the condensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

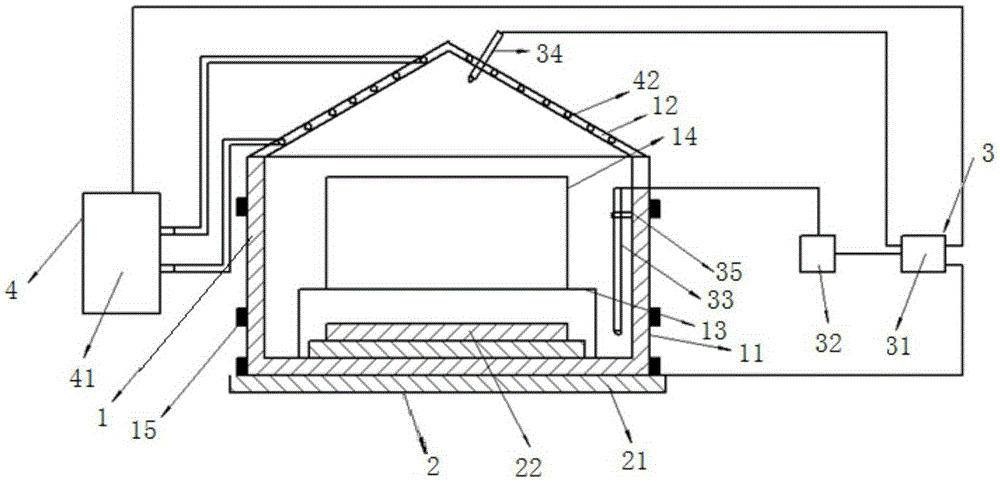

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] see figure 1 , the low-magnification steel thermal acid etching device provided by the present invention includes an acid etcher 1 and an electromagnetic induction heating device 2 . Wherein, the acid etcher 1 includes a tank body 11 and a tank cover 12, preferably, the tank body 11 and the tank cover 12 are enclosed in a sealed structure to prevent acid mist from leaking out and polluting the environment. The electromagnetic induction heating device includes an induction plate 21 and a heating plate 22 , the tank body 11 is placed on the induction plate 21 , and the heating plate 22 is located at the bottom of the cavity of the tank body 11 . Further preferably, a heat insulating disc 23 is set between the heating plate 22 and the bottom of the tank body 11, so as to avoid the local temperature of the tank body 11 being too high; furth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com