Packaging system and packing method for sealed glass packaging body through laser

A technology of sealing glass and packaging system, which is applied in the fields of electric solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., and can solve the problems of low yield, difficult realization, cumbersome packaging process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

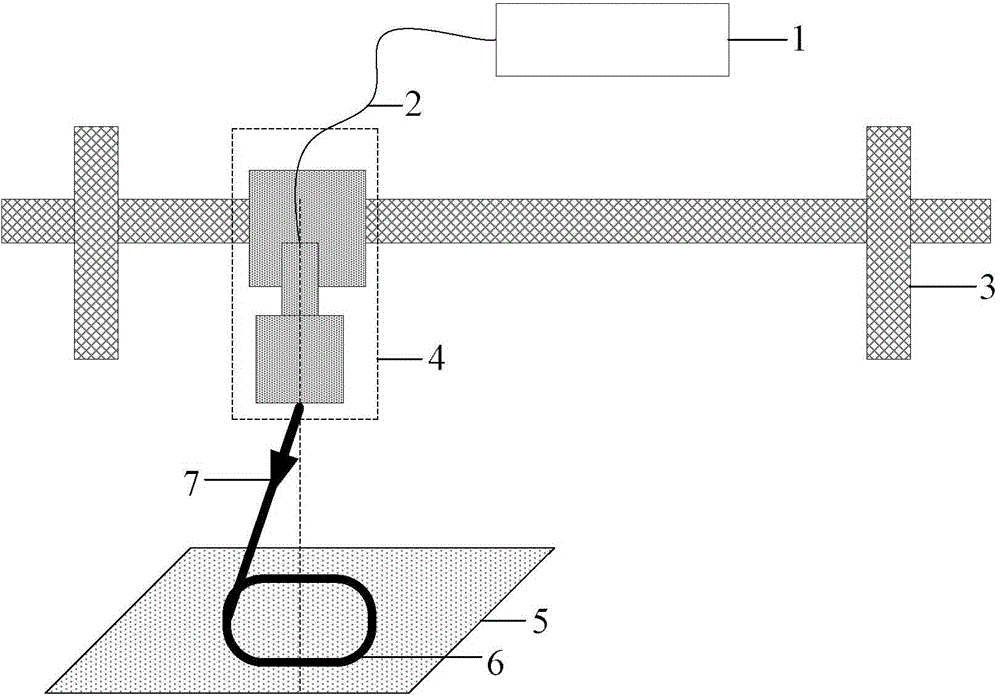

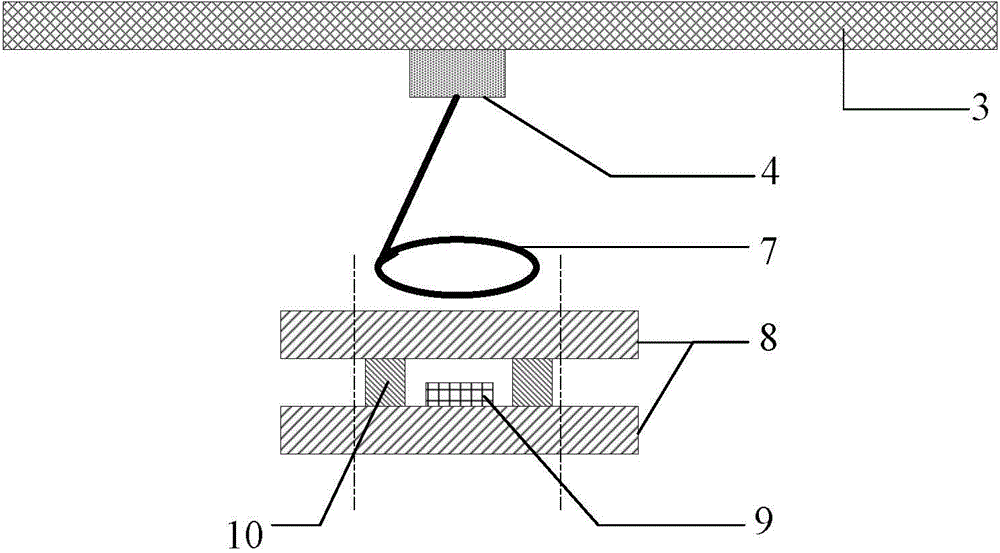

[0057] Please refer to Figure 1 to Figure 4 , in this embodiment, a light-sealed glass package packaging system is proposed, including: a laser 1, a gantry 3, and a laser scanning unit 4, wherein the laser scanning unit 4 is arranged on the gantry 3, The laser 1 emits laser light and projects it onto the sealed glass package to be packaged through the laser scanning unit 4 .

[0058] In this embodiment, the laser 1 is a CO2 laser, which is connected to the laser scanning unit 4 through an optical fiber 2. The wavelength range of the laser 7 emitted by the laser 1 is 800nm to 900nm, such as 850nm, and its working power range is 100W~500W, such as 300W; the laser scanning unit 4 is a vibrating mirror laser scanning unit, including a mirror 4' (such as Figure 4 shown), scanning motor and servo drive unit ( Figure 4 not shown), wherein the servo drive unit sends a deflection angle signal to the scanning motor, and the scanning motor controls the mirror 4' to deflect the ang...

Embodiment 2

[0067] Please refer to 5. In this embodiment, the laser-sealed glass package packaging system is a single-vibration mirror laser scanning system, which is packaged by a single-vibration mirror area packaging method. The method for encapsulating the area of the single vibrating mirror comprises the steps of:

[0068] Divide a hermetic glass package to be packaged into multiple packaging areas, Figure 5 Only two packaging areas are shown in , wherein the heating window 5 can cover the plurality of packaging areas as a whole;

[0069] When encapsulating one of the encapsulation areas, the gantry 3 remains static, and the laser scanning unit 4 rotates, so that the laser 7 performs periodic encapsulation on the encapsulation line in the encapsulation area according to a predetermined track and speed. scanning;

[0070] After the encapsulation of the encapsulation area is completed, the gantry 3 drives the laser scanning unit 4 to move to the next encapsulation area along the s...

Embodiment 3

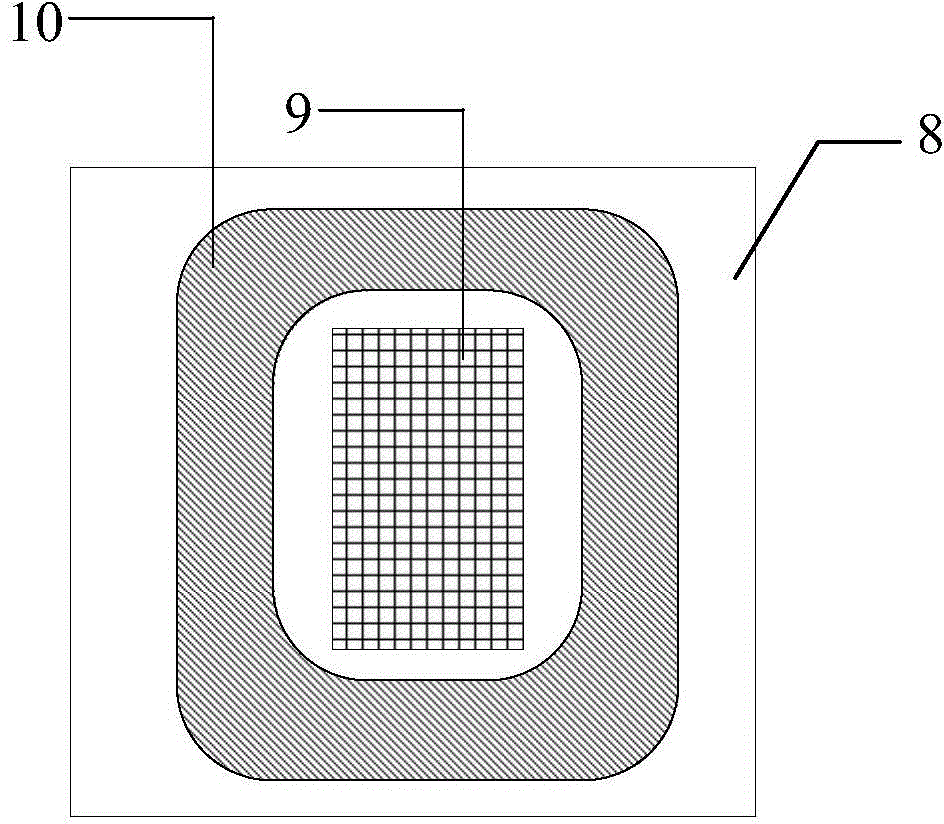

[0073] In this embodiment, the laser-sealed glass package packaging system is a single-galvanometer laser scanning system, and the large-size sealed glass package is packaged by using a single-galvanometer scanning packaging method, that is, a gantry-driven laser beam scanning method, The single vibration mirror scanning encapsulation method is as follows: when encapsulating a sealed glass encapsulation body, while the gantry 3 moves along the upper plane of the encapsulation line 6, the laser beam moves to the encapsulation according to a predetermined track and speed The glass frit 10 at the packaging line 6 is scanned until all the sealed glass packages to be packaged are packaged.

[0074] like Figure 6a , 6b As shown, the vibrating mirror in the laser scanning unit vibrates rapidly so that the laser beam rotates at a certain angle and speed, forming a heating window 5 within the laser beam coverage area. The laser beam repeatedly scans the packaging line in the heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com