Preparation method for lamiophlomis rotata extract and application thereof

A unique and extract technology, applied in the field of preparation of unique extracts, can solve the problems of dull foam gloss, reduced purchase rate and recommendation rate of cleaning experience, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

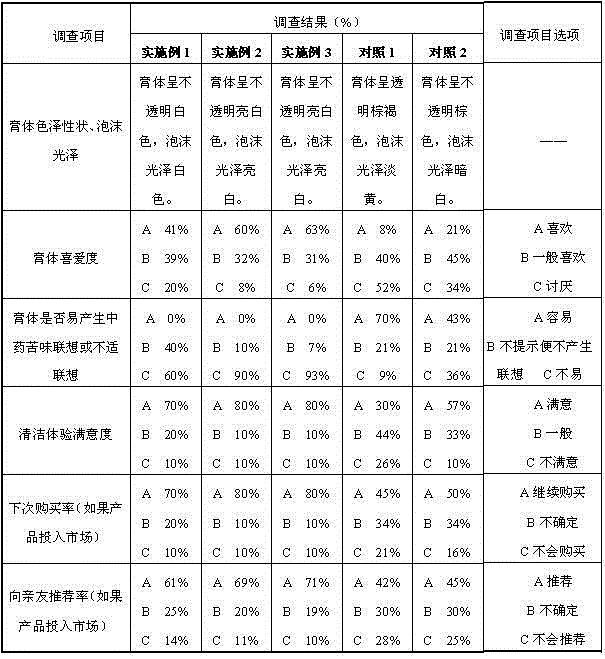

Examples

Embodiment 1

[0064] Embodiment 1 unique extract preparation method:

[0065] ①Take the unique medicinal material, add 6 times its mass of water, decoct and extract 3 times, 0.5 hours each time, combine the extracts, filter, and concentrate to obtain an extraction concentrate with a mass ratio of 2:1 to the unique medicinal material; D101 macroporous adsorbent resin was applied to the above-mentioned extract concentrate, and the sample loading speed was 0.5BV / hour. First, it was eluted with water until the obtained eluent A was colorless, and the eluent A was discarded. 70% ethanol was eluted, and the eluent B was collected for subsequent use;

[0066] ②Add 30% activated carbon of the unique medicinal material mass to the eluent B obtained in step ①, stir at 50°C for 2 hours, let it stand and settle until the activated carbon is completely precipitated, and take the obtained liquid part A and solid part respectively for later use;

[0067] ③Add 70% ethanol twice the weight of the unique m...

Embodiment 2

[0069] Embodiment 2 unique extract preparation method:

[0070] ①Take the unique medicinal material, add water 10 times its mass, decoct and extract once, 2.5 hours each time, combine the extracts, filter, and concentrate to obtain an extraction concentrate with a mass ratio of 1.5:1 to the unique medicinal material; D101 macroporous adsorption resin on the above-mentioned extraction concentrated solution, the sample loading speed is 4BV / hour, first elute with water until the obtained eluent A is colorless, discard the eluent A, and then use 50 % ethanol was eluted, and the eluent B was collected for subsequent use;

[0071] ②Add 40% activated carbon of the unique medicinal material mass to the eluent B obtained in step ①, boil and stir for 0.5h, centrifuge, and take the obtained liquid part A and solid part respectively for later use;

[0072] ③Add 50% ethanol which is 4 times the weight of the unique medicinal material to the solid part obtained in step ②, boil and stir e...

Embodiment 3

[0074] Embodiment 3 unique extract preparation method:

[0075]①Take the unique medicinal material, add 8 times its mass of water, decoct and extract twice, 1 hour each time, combine the extracts, centrifuge, and concentrate to obtain an extraction concentrate with a mass ratio of 4:1 to the unique medicinal material; D101 macroporous adsorption resin on the above-mentioned extraction concentrated solution, the loading speed is 2BV / hour, first elute with water until the obtained eluent A is colorless, discard the eluent A, and then use 60 % ethanol was eluted, and the eluent B was collected for subsequent use;

[0076] ② Add activated carbon with 35% of the weight of the unique medicinal material to the eluent B obtained in step ①, stir at 70°C for 1 hour, let it stand for precipitation until the activated carbon is completely precipitated, and take the obtained liquid part A and solid part respectively for later use;

[0077] ③Add 60% ethanol which is 3 times the weight of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com