Tool for welding impeller of centrifugal blower

A centrifugal blower, welding tooling technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increased labor intensity, increased workload, low production efficiency, and difficult to fix, and improve welding processing efficiency. , The effect of reducing the time of grinding welds and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

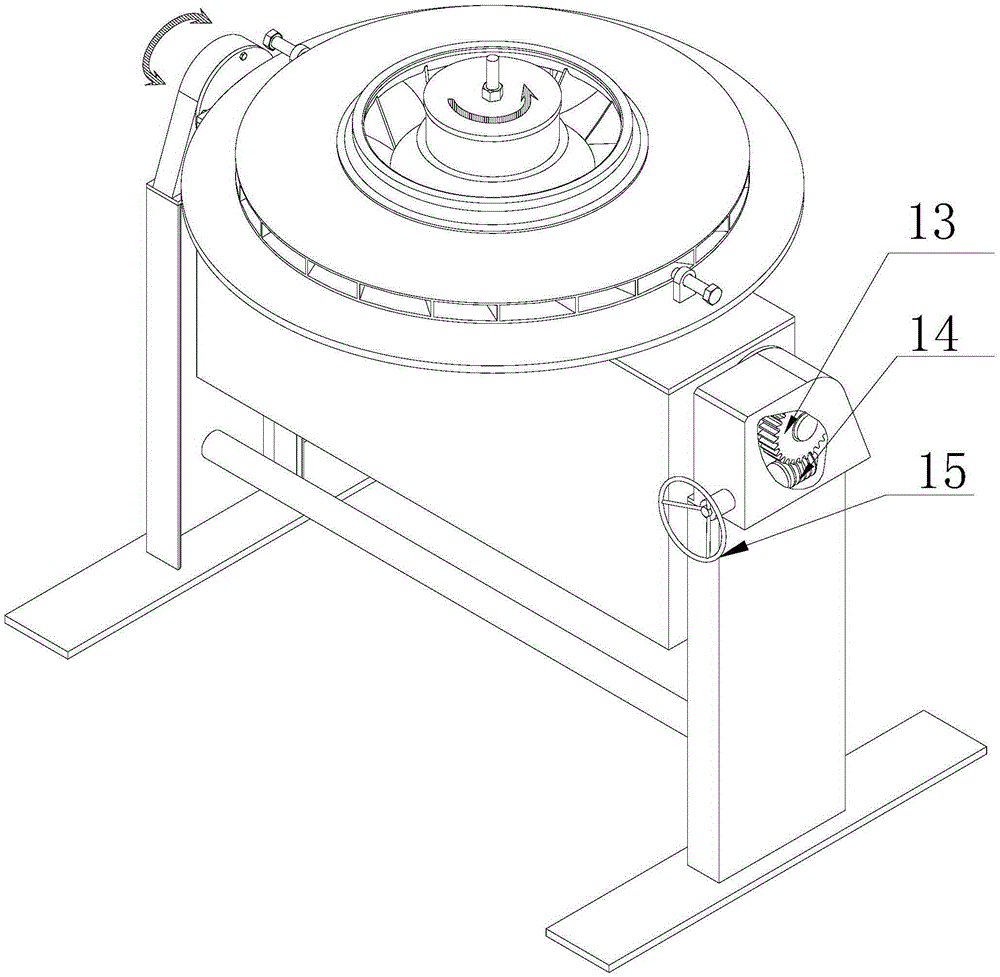

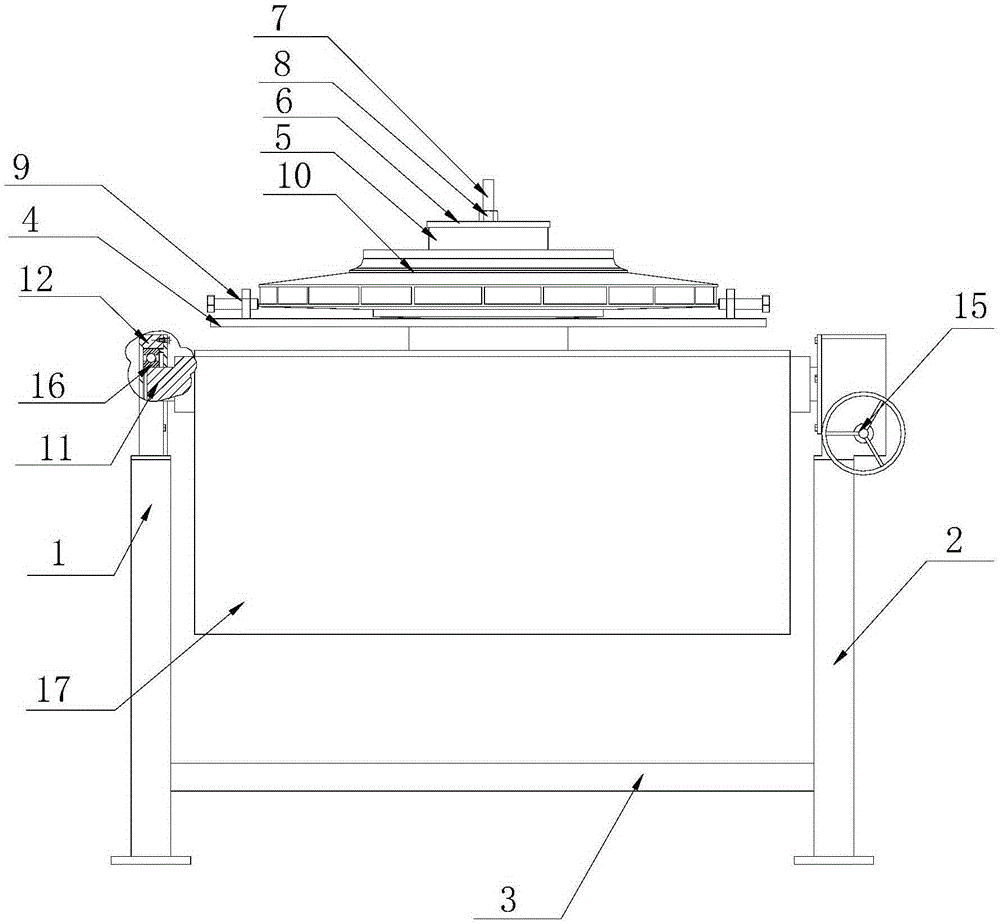

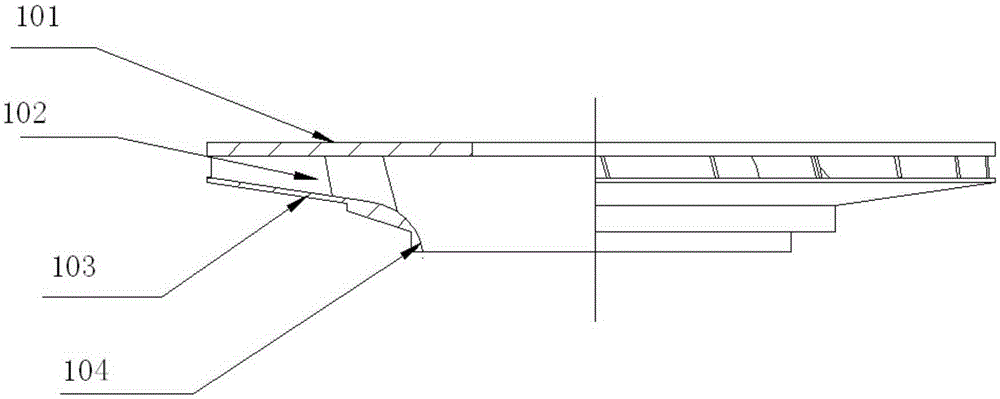

[0011] Referring to the accompanying drawings, the impeller is mainly welded by a wheel disc 101, a wheel cover 103, long and short blades 102, and an inlet ring 104. An impeller welding tool for a centrifugal blower, which includes a bracket, a rotating mechanism and a turning mechanism. The bracket includes a left bracket 1 and a right bracket 2. The left bracket and the right bracket are respectively fixed on the base surface. The space is connected by a reinforcing tube 3; the rotating mechanism includes a support plate 4, a pressure ring 5, a gland 6, a screw rod 7, a nut 8 and a limit fixing bolt 9, and two limit fixing bolts are provided, and the two limit fixing bolts are used to support The center of the disc circle is set symmetrically, and the impeller 10 is connected with the support disc through a pressure ring, gland, screw and nut. The impeller can rotate around the screw rod on the support disc and can be fixed by limit fixing bolts; the turning mechanism includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com