Conveniently-assembled polyurethane flexible foam composite board

A technology of polyurethane soft foam and composite board, applied in the field of composite board, can solve the problems of mechanical strength without resistance to deformation, falling off, troublesome operation, etc., and achieve the effect of fast positioning and leveling operation, prolonging the service period, and obvious effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

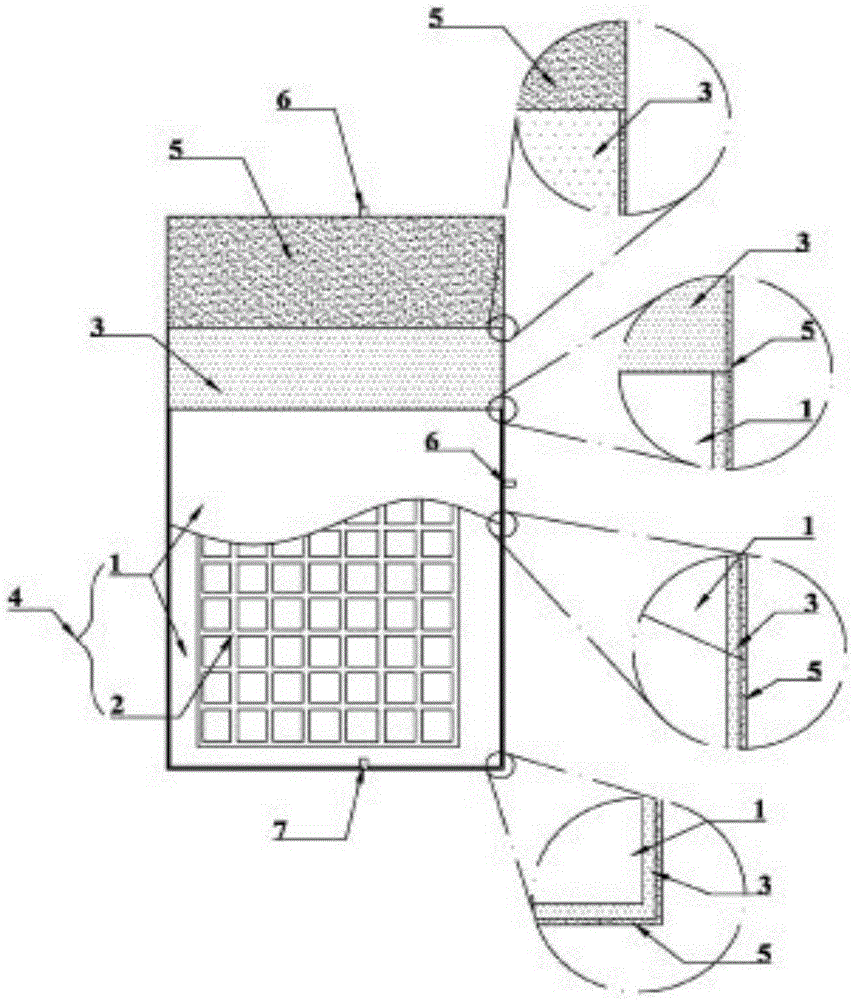

[0016] The main structure of this embodiment, such as figure 1 As shown, a polyurethane soft foam composite board that is easy to assemble includes a polyurethane soft foam layer 1, a metal alloy mesh skeleton 2, and an anti-aging layer 3. The anti-aging layer 3 is made of polyethylene and an anti-aging agent through a composite process. Its six sides are coated on the outer surface of the composite board core 4 formed by the polyurethane soft foam layer 1 and the metal alloy mesh skeleton 2, wherein the polyurethane soft foam layer 1 itself has a good sound absorption effect, and on its surface Setting the sound-absorbing micropores can increase the specific surface area of the polyurethane soft foam and greatly improve the sound-absorbing effect; the full coating of the anti-aging layer 3 can prolong the service life of the composite board and improve the functionality of the material.

Embodiment 2

[0018] This embodiment is further limited on the basis of Embodiment 1. A connecting tenon 6 is provided on a group of adjacent sides of the composite board core 4, and a connection tenon 6 matching the shape of the connecting tenon 6 is provided on the other group of adjacent sides of the composite board core 4. The tenon and groove 7, wherein the shape of the connecting tenon 6 can be cylindrical, and the shape of the tenon and groove 7 matches the shape of the connecting tenon 6, which is convenient for the upper and lower positioning between adjacent boards and between the insulation boards when the insulation boards are spliced. The whole is leveled internally and externally, and the tenon connecting the tenon 6 makes the action of inserting into the tenon groove 7 smoother and easier to disassemble. Other structures involved in the present invention are common knowledge in the field and will not be repeated here.

Embodiment 3

[0020] This embodiment is further defined on the basis of the above embodiments, the flexible polyurethane foam layer 1 has a rectangular structure and has two layers. The polyurethane soft foam layer 1 itself has a good sound-absorbing effect, and sound-absorbing micropores can be provided on its surface to further increase the specific surface area of the polyurethane soft foam layer, thereby further improving the sound-absorbing effect. Other structures involved in the present invention are common knowledge in the field and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com