Rotational flow atomizing precombustion type heavy oil burner

A heavy oil combustion and pre-combustion technology, which is applied in the direction of burners, combustion methods, and controlled combustion, can solve the problem of high concentration and achieve the effects of less investment, significant energy saving and environmental protection benefits, and compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The invention will be further described below in conjunction with the accompanying drawings.

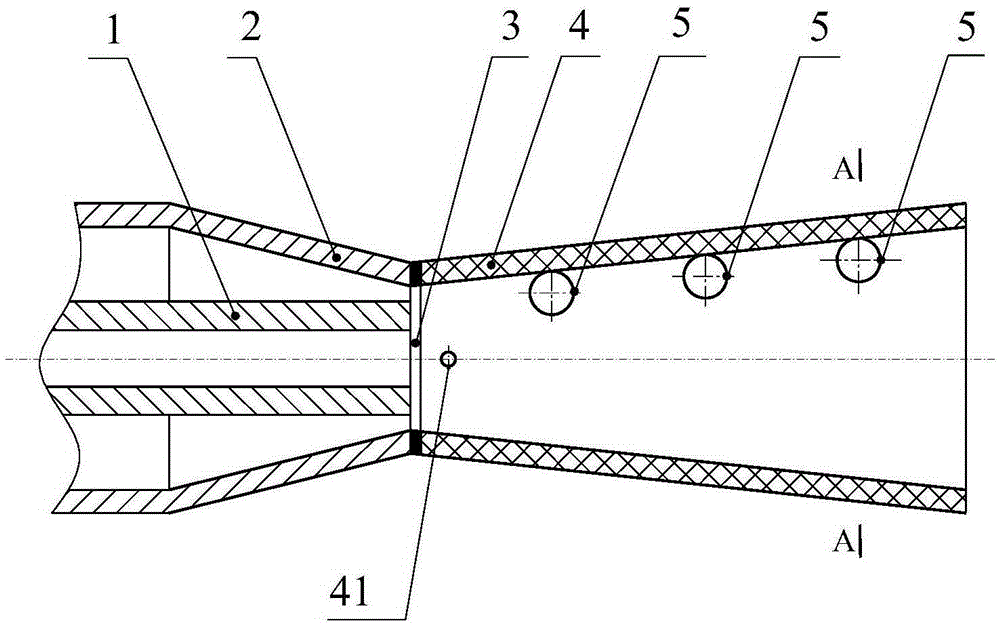

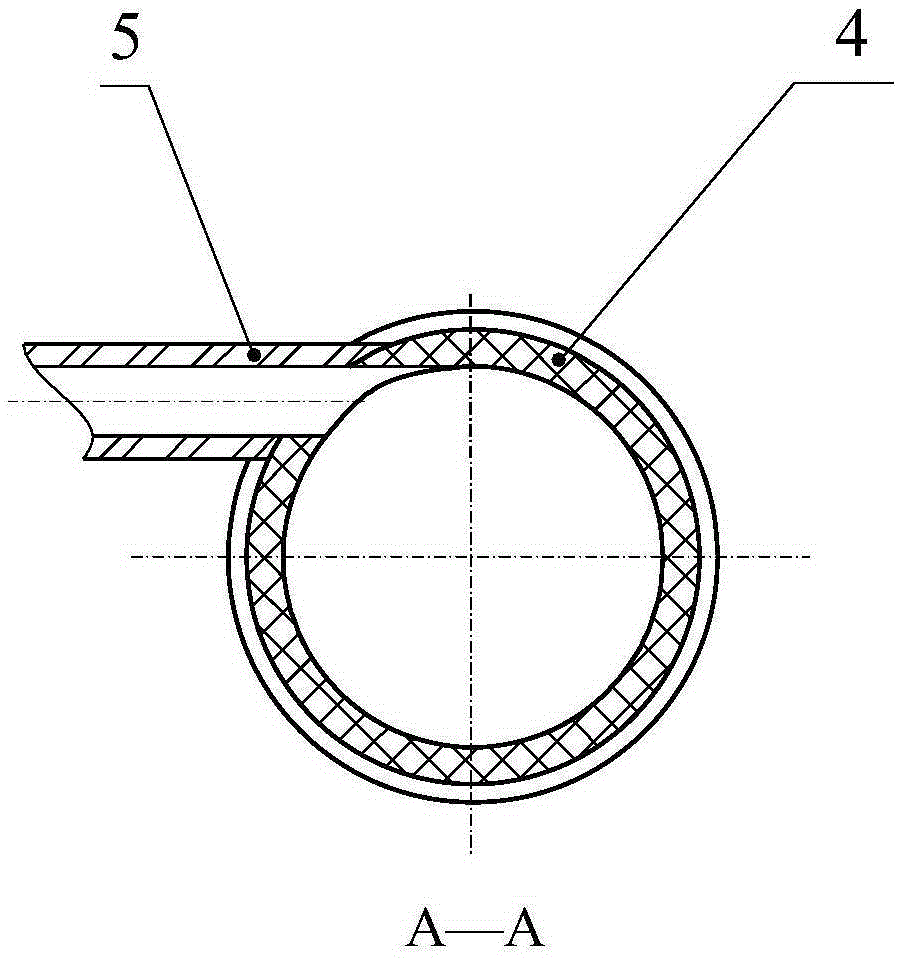

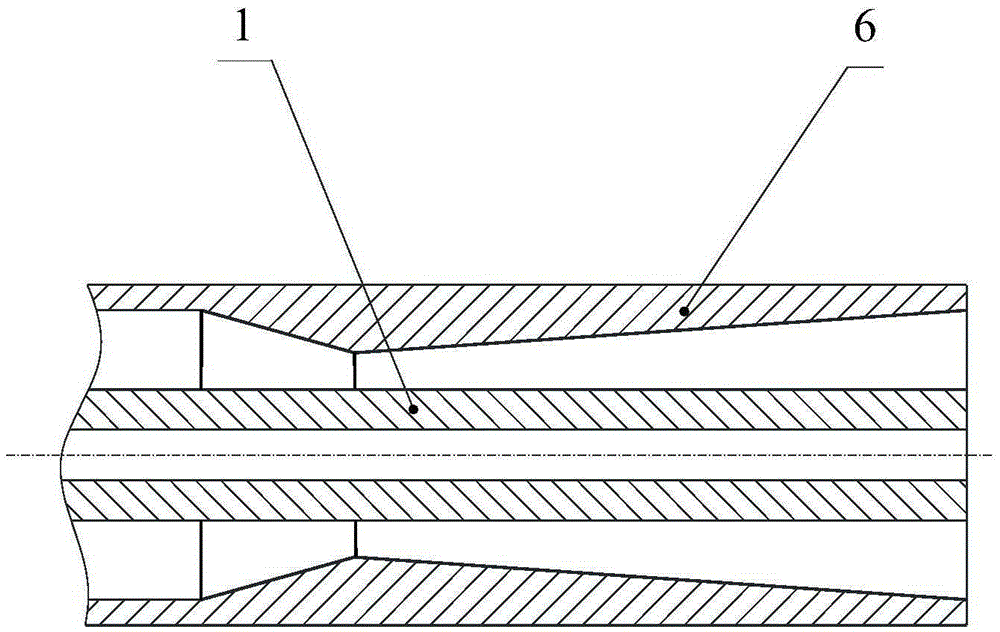

[0014] as attached figure 1 And attached figure 2 As shown, the swirling atomization pre-combustion heavy oil burner mainly includes oil pipe 1, tapered nozzle pipe 2, gasket 3, burner brick 4 and numerous air supply pipes 5. The air flow channel of the supplementary air pipe 5 and the oil passage of the oil pipe 1 are all circular channels with equal area, and the pipe material of the oil pipe 1 and the pipe material of the air supplement pipe 5 are all metal materials. The side wall of the burner brick 4 is provided with an ignition hole 41 . Burner brick 4, washer 3, tapering nozzle 2 and oil pipe 1 have four central axes collinear, oil pipe 1 is covered with tapering nozzle 2, and the exit end face of tapering nozzle 2 is coplanar with oil pipe 1 outlet end face. The gasket 3 is arranged between the outlet end face of the tapering nozzle 2 and the inlet end face of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com