Method for measuring multidirectional displacement by using multi-core fiber

A multi-core optical fiber and multi-directional technology, applied in the field of optical fiber, achieves the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

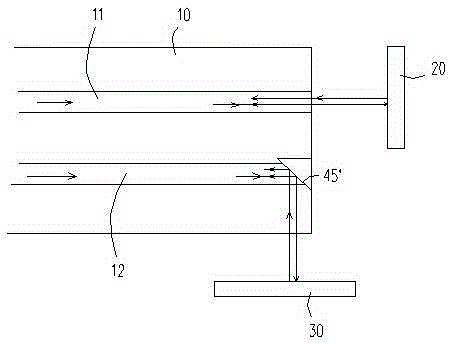

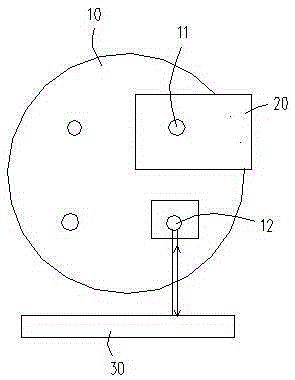

[0023] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

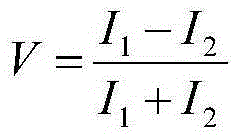

[0024] The equipment used in the multi-directional displacement measurement of the multi-core optical fiber in the present invention includes a laser, a fiber grating demodulator, a fan-out device, a photodetector, an acquisition card and a computer, wherein the laser is used as a light source, and the multi-core optical fiber and the photodetector are connected together. The connected fan-out device is also an important part of the measurement system. Its function is to output each fiber core of the connected multi-core fiber in the form of a single-mode fiber, and the single-mode fiber is placed in a V-groove array. When installing, firstly couple the V-groove array composed of four single-mode optical fibers to the V-groove port of the fan-out device, and adjust it by using reflectivity matching gel and a manual three-dimensional translation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com