Method for testing compression performance of carbon-fiber reinforced resin-based thin-wall composite pipe

A technology for reinforcing resin-based and composite materials, which is used in the preparation of test samples and the application of stable tension/pressure to test the strength of materials. The effect of increasing stability, avoiding additional bending moments, and reducing dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

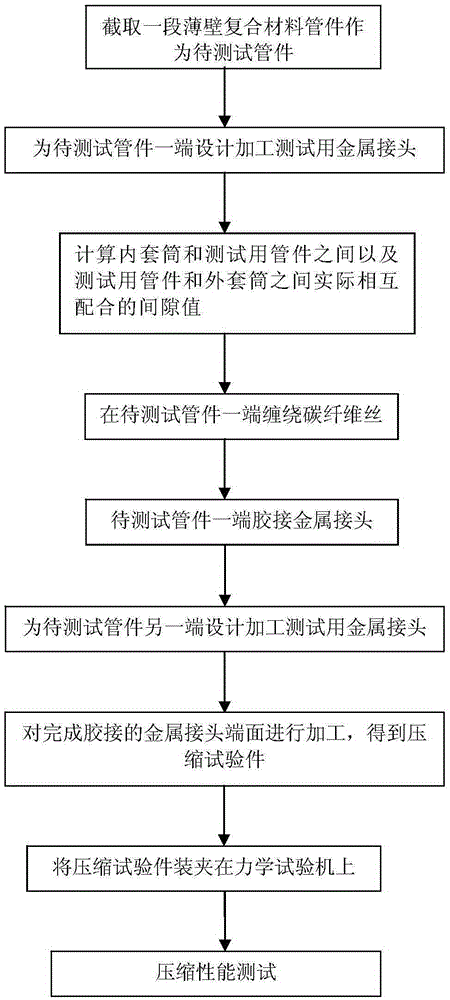

Method used

Image

Examples

Embodiment

[0047] Take the compression performance test of carbon fiber reinforced resin-based thin-walled composite pipe fittings with an inner diameter of Φ24mm and a wall thickness of 0.6mm as an example:

[0048] 1. Use a diamond grinding wheel to cut a length of 230mm from the carbon fiber reinforced resin-based thin-walled composite pipe to be tested as a test. When cutting, select a glass rod with a diameter of Φ24mm and insert it into the carbon fiber-reinforced resin-based thin-walled composite pipe to be tested. , using a diamond grinding wheel to mill the two end faces of the test pipe fittings obtained after interception, to ensure that the parallelism of the two end faces is 0.05mm.

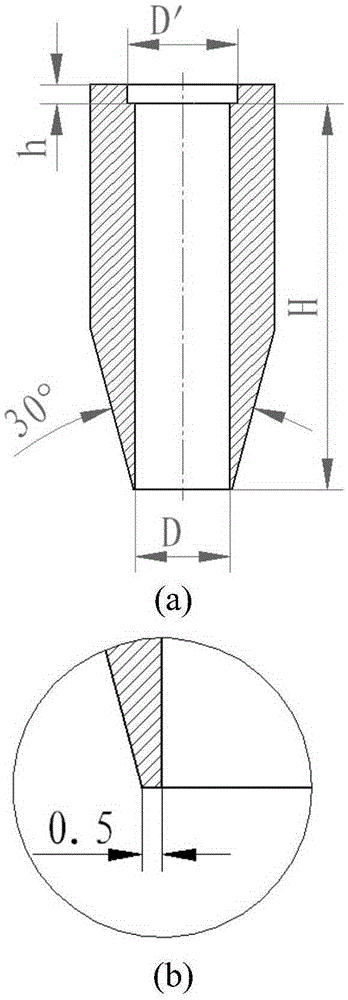

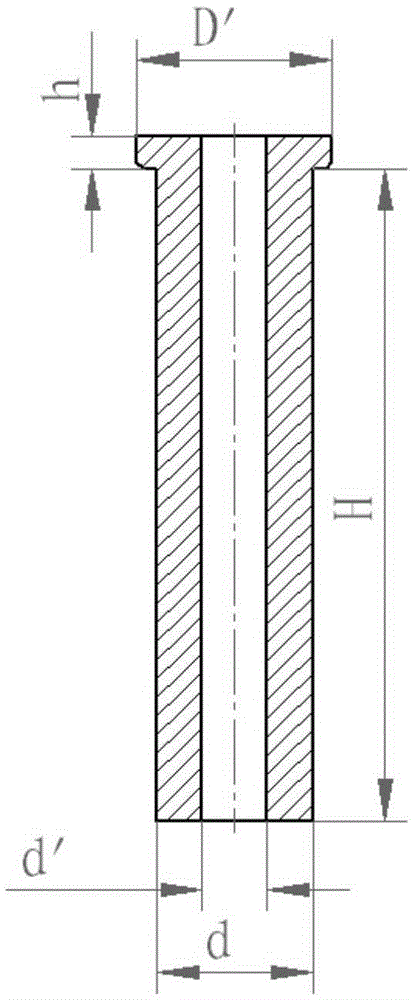

[0049] 2. According to the inner and outer diameters of the test fittings obtained in step 1, one end of the test fittings is used to design and process a metal joint for testing. The metal joint includes an inner sleeve and an outer sleeve, and the inner sleeve is a hollow cylinder. It has a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com