A frame-rod slow wave structure

A technology of slow-wave structure and slow-wave circuit, which is applied to the circuit components of time-of-flight tubes, etc., which can solve problems such as harmonic oscillation, limited application development, and small fundamental wave coupling impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

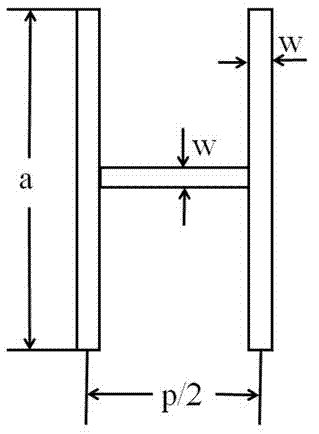

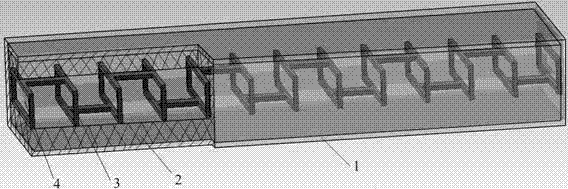

[0024] This facility mode takes the frame-rod slow-wave device working in the 50-60 GHz band with the traveling wave tube as an example: it includes a rectangular cylindrical waveguide (1), a rectangular cylindrical insulating dielectric substrate (2), a frame-rod metal The slow wave circuit (3) and the central vacuum interaction area (4); the rectangular cylindrical waveguide (1), the rectangular cylindrical insulating dielectric substrate (2), the frame-rod metal slow wave circuit (3) and the central vacuum The central axes of the interaction area (4) coincide; the rectangular cylindrical insulating dielectric substrate (2) is set in the rectangular cylindrical waveguide (1); the frame-rod metal slow wave circuit (3) is set in the rectangular cylindrical On the inner surface of the shaped insulating medium substrate (2); the frame-rod metal slow wave circuit (3) is composed of a plurality of metal wire frames with the same shape and size and connecting rods between the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com