Air cathode, preparation method of air cathode and microbiological fuel cell

An air cathode and anode technology, which is applied in the fields of materials, energy, and the environment, can solve problems such as the complexity of the preparation process, and achieve the effects of improving electrode performance, improving electrode conductivity, improving efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

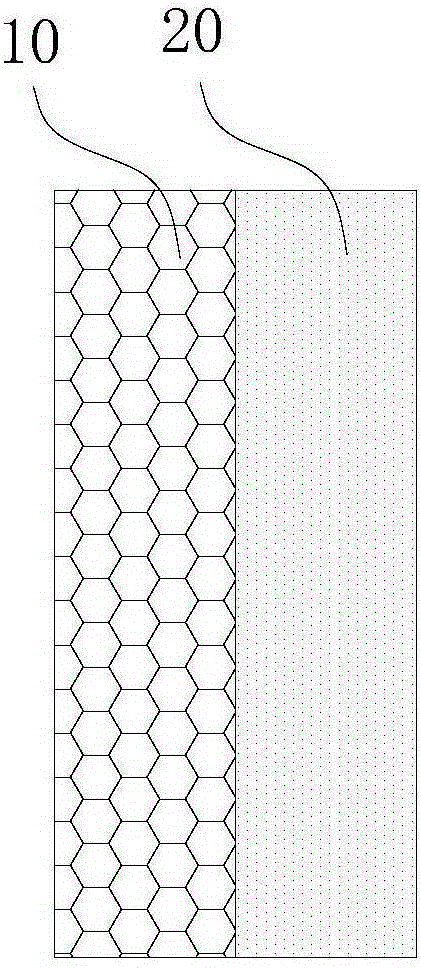

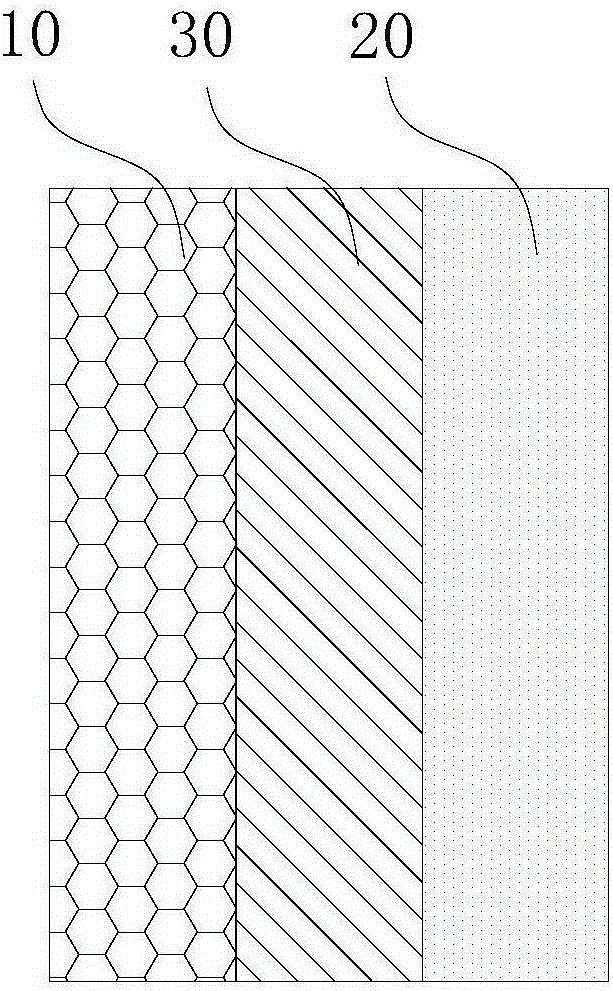

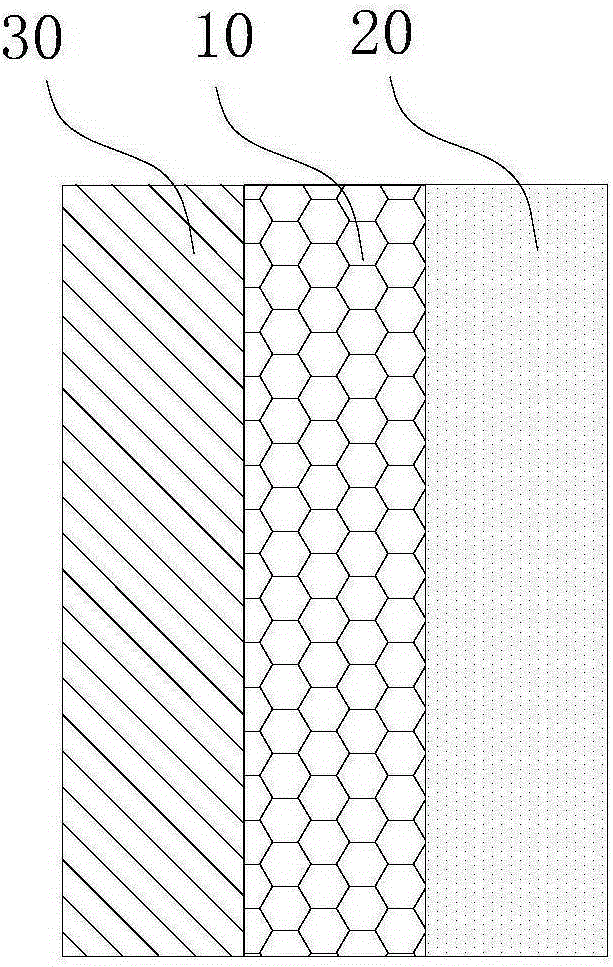

Image

Examples

Embodiment 1

[0076] Embodiment 1: preparation catalyst layer

[0077] Cut the 40-mesh nickel mesh into a rectangle of 4cm×8cm, put it in distilled water and ultrasonically clean it for 5-10 minutes, and remove dust and other impurities on the surface of the nickel mesh. The cleaned nickel mesh is curled into a shape that can be put into a quartz boat to ensure that the nickel mesh has no contact with each other, so that it can be in good contact with the reaction gas. Place the nickel mesh on the quartz boat, the quartz boat is connected with a copper wire, wind the iron wire at the end of the copper wire, and slowly push the quartz boat into the middle of the reaction chamber. Make sure that the wire part stays outside the reaction chamber. Wrap the heating tape in the preheating zone and set the temperature at 270 degrees Celsius. Check the airtightness of the reaction device, if the airtightness is good, feed 300mL / min of argon to discharge the air in the device. The furnace temperat...

Embodiment 2

[0078] Embodiment 2: preparation catalyst layer

[0079] Referring to Example 1, the difference is that the injection rate of acetonitrile is 10 μL / min, and the injection time is 5 minutes.

Embodiment 3

[0080] Embodiment 3: preparation catalyst layer

[0081] Referring to Example 1, the difference is that the injection rate of acetonitrile is 20 μL / min, and the injection time is 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cod | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com