A kind of nitrogen-doped graphene/activated carbon composite material and its preparation method and application

A nitrogen-doped graphene and composite material technology, applied in the field of nitrogen-doped graphene/activated carbon composite material and its preparation, can solve the problems of complex process, high production cost, uneven dispersion, etc., and achieves increasing contact area and improving monolayer rate. , Use the effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

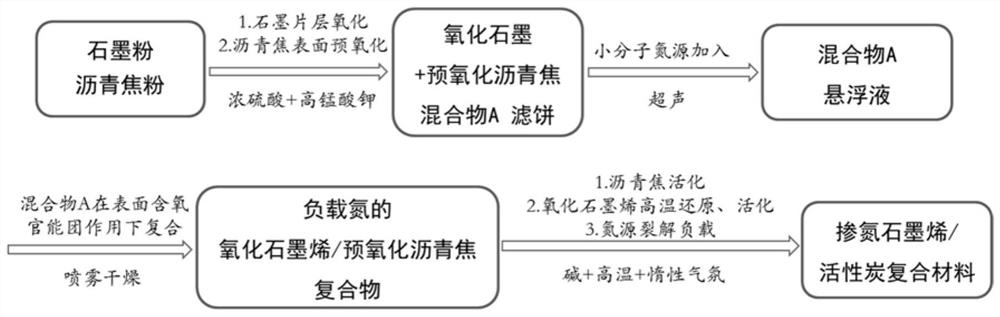

[0028] A preparation method of nitrogen-doped graphene / activated carbon composite material, combining figure 1 , including the following steps:

[0029] 1) Add concentrated acid and graphite powder into the reaction kettle and mix well; slowly add KMnO 4 And fully mix the reaction; add powdered pitch coke to continue the mixing reaction; slowly add pure water to continue the mixing reaction; add hydrogen peroxide to end the reaction.

[0030] Among them, the graphite powder is one of 100-20000 mesh flake graphite, expanded graphite, and intercalated graphite; the powdered pitch coke is a pitch coke with a particle size of ≤200 μm after crushing, and the ash content is ≤10%; the concentrated acid is preferably concentrated sulfuric acid, concentrated At least one of phosphoric acid and concentrated nitric acid; hydrogen peroxide is commercially available hydrogen peroxide with a concentration of 30%; the mass ratio of each material added is: 1 part of graphite powder, 70-400 p...

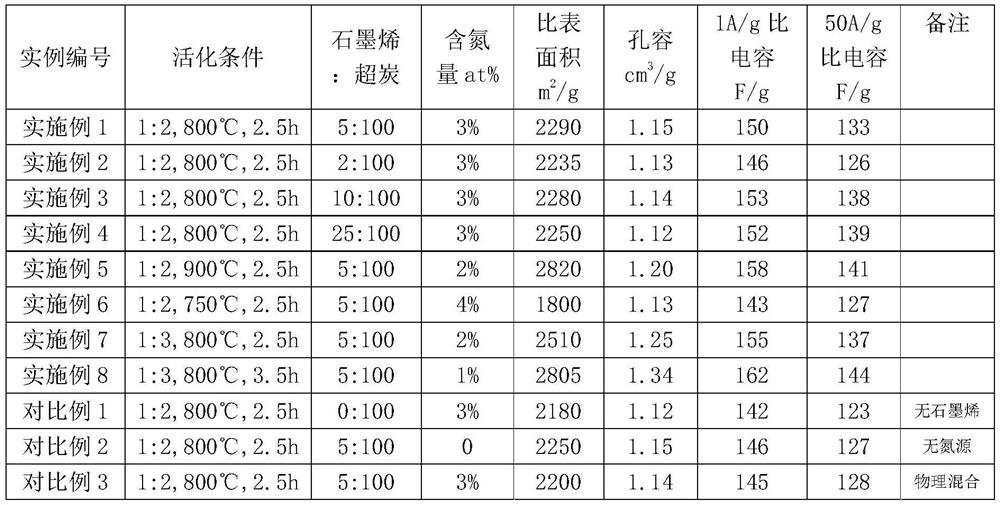

Embodiment 1

[0039] Add 10kg of concentrated sulfuric acid into a stirred tank with an interlayer, add 50g of 1000 mesh flake graphite powder during the stirring process, and stir for 30min to mix evenly, slowly add 200g of KMnO 4 In this process, 5°C cooling water is passed through the interlayer of the reaction kettle; the above-mentioned solid-liquid mixture is stirred and reacted for 180 minutes, and then 1000 g of pitch coke that has been crushed and passed through a 300 mesh sieve is added, and the stirring reaction is continued for 60 minutes. After lowering the temperature of the above solid-liquid mixture to 30°C, slowly add 10kg of distilled water, keep the temperature in the kettle at 60°C and stir for 120min, then add 200g of hydrogen peroxide and stir for 30min; add 100ml of 1‰ polyacrylamide flocculant to make the solid in the suspension After fully flocculating, filter, and wash the filter cake with deionized water until pH=3; disperse the filter cake in water, add 300g of me...

Embodiment 2

[0041] Add 15kg of concentrated sulfuric acid into a stirred tank with an interlayer, add 50g of 1000 mesh flake graphite powder during the stirring process, and stir for 30min to mix evenly, slowly add 250g of KMnO 4 In this process, 5°C cooling water is passed through the interlayer of the reaction kettle; the above-mentioned solid-liquid mixture is stirred and reacted for 180 minutes, and then 1700 g of pitch coke that has been crushed and passed through a 300-mesh sieve is added, and the stirring reaction is continued for 60 minutes. After lowering the temperature of the above solid-liquid mixture to 30°C, slowly add 15kg of distilled water, keep the temperature in the kettle at 60°C and stir for 120min, then add 250g of hydrogen peroxide, and stir for 30min; the rest of the steps are the same as in Example 1. The composite graphene: activated carbon mass ratio is about 2:100, the nitrogen content in the composite material is 3at%, and the specific surface area is 2235m 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com