Integrated control method for low-temperature flue gas pollutants

A technology of low-temperature flue gas and control method, which is applied in the field of flue gas purification, and can solve problems such as the work effect needs to be improved, the industrial application is limited, and the microwave reactor is expensive.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

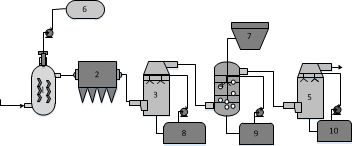

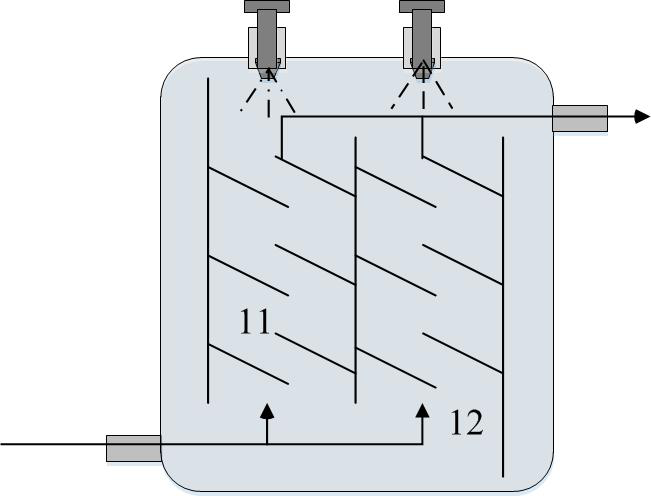

[0023] Particulate matter in flue gas, SO 2 , NO, Hg 0 Concentrations were 15 g / Nm 3 , 2000ppm, 400ppm and 50 μg / Nm 3 , flue gas temperature 110 o C. The flue gas flows through the agglomeration chamber (1) sequentially. At this time, the agglomeration agent storage tank (6) is opened, and it is sprayed into the agglomeration chamber (1) through the compressor and the two-fluid nozzle. The residence time of the flue gas in the agglomeration chamber is 3-5s. ; The outflowing flue gas enters the bag filter (2) for primary purification of dedusting; the primary purification flue gas enters the desulfurization tower (3), and the limestone slurry (8) is turned on for desulfurization, and the secondary purified flue gas after desulfurization The gas enters the oxidation reactor (4), turns on the ultra-micro bubble generator (7), the ultra-micro bubbles enter the oxidation reactor (4), triggers the oxidant (9) to form an oxidation reaction, the oxidation reaction time is 3-8s, and...

Embodiment 2

[0025] Particulate matter in flue gas, SO 2 , NO, Hg 0 Concentrations were 25 g / Nm 3 , 2000ppm, 400ppm and 70 μg / Nm 3 , flue gas temperature 105 o C. The flue gas flows through the agglomeration chamber (1) sequentially. At this time, the agglomeration agent storage tank (6) is opened, and it is sprayed into the agglomeration chamber (1) through the compressor and the two-fluid nozzle. The residence time of the flue gas in the agglomeration chamber is 3-5s. ; The outflowing flue gas enters the bag filter (2) for primary purification of dedusting; the primary purification flue gas enters the desulfurization tower (3), and the limestone slurry (8) is turned on for desulfurization, and the secondary purified flue gas after desulfurization The gas enters the oxidation reactor (4), turns on the ultra-micro bubble generator (7), the ultra-micro bubbles enter the oxidation reactor (4), triggers the oxidant (9) to form an oxidation reaction, the oxidation reaction time is 3-8s, and...

Embodiment 3

[0027] Particulate matter in flue gas, SO 2 , NO , Hg 0 Concentrations were 25 g / Nm 3 , 1450 ppm, 500ppm and 64 μg / Nm 3 , flue gas temperature 110 o C. The flue gas flows through the agglomeration chamber (1) sequentially. At this time, the agglomeration agent storage tank (6) is opened, and it is sprayed into the agglomeration chamber (1) through the compressor and the two-fluid nozzle. The residence time of the flue gas in the agglomeration chamber is 3-5s. ; The outflowing flue gas enters the bag filter (2) for primary purification of dedusting; the primary purification flue gas enters the desulfurization tower (3), and the limestone slurry (8) is opened for desulfurization, and the secondary purification smoke after desulfurization The gas enters the oxidation reactor (4), turns on the ultra-micro bubble generator (7), the ultra-micro bubbles enter the oxidation reactor (4), triggers the oxidant (9) to form an oxidation reaction, the oxidation reaction time is 3-8s, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com